Method for realizing additive manufacturing through cold gas dynamic spray

A technology of cold air power spraying and additive manufacturing, applied in pressure inorganic powder coating and other directions, can solve problems such as difficult additive manufacturing, and achieve the effect of good mechanical properties and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

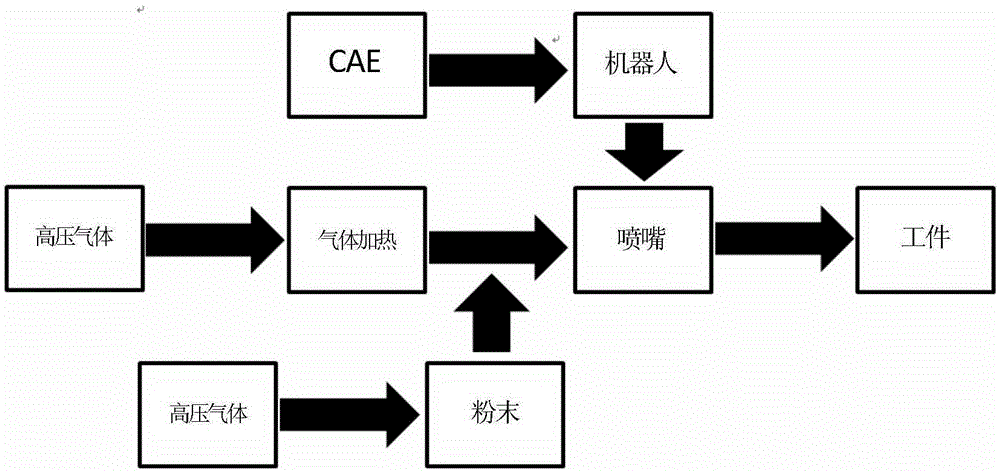

Method used

Image

Examples

Embodiment 1

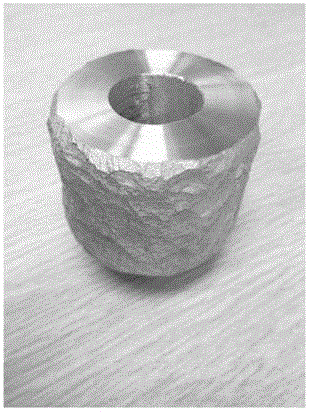

[0030] The spraying particle size is 400-500 mesh pure Al powder, the operating pressure is 1.5MPa, the gas heating temperature is 380°C, and the incident angle is 60°-90°. The injection direction is controlled according to the CAD file program, and the injection distance is moved in accordance with the growth direction to realize the 3D printing of pure aluminum special-shaped parts. In this embodiment, the prepared workpiece has a bonding strength of 40-200 MPa, a porosity of 0.1%-0.5%, and a surface roughness Ra of 40 μm-160 μm. Such as figure 2 As shown, it can be seen from the preparation of aluminum materials by using the cold air power spraying 3D printing technology that the cold air power spraying additive manufacturing technology can manufacture workpieces with complex shapes to a certain extent.

Embodiment 2

[0032] Spray pure Cu powder with a particle size of 325-600 mesh, operating pressure of 2.5MPa, gas heating temperature of 500°C, incident angle of 60°-90°, and the print head rotates with the surface of the opposite conductor. Copper powder is deposited on the surface of the original substrate layer by layer, and the added part has good conductivity after measurement, realizing the additive manufacturing of easily oxidizable materials. In this embodiment, the bonding strength of the prepared workpiece reaches 65-200 MPa, the porosity is 0.2%-1.2%, and the electrical conductivity is close to that of pure copper.

Embodiment 3

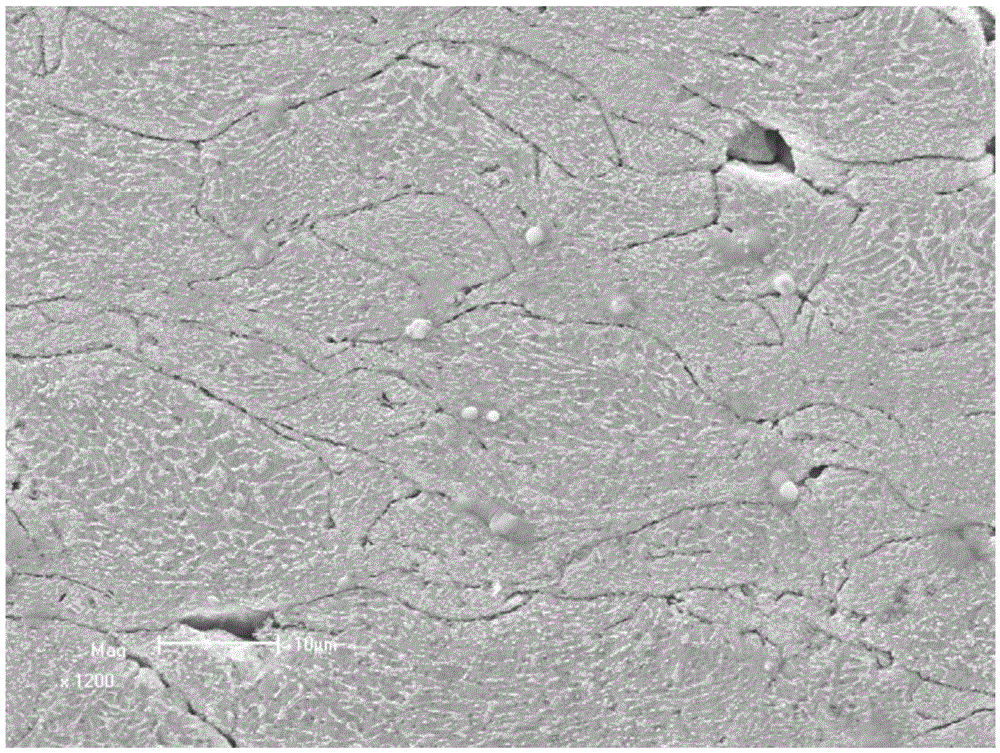

[0034] The particle size of spraying is 450-500 mesh amorphous Al powder, the operating pressure is 1.8MPa, the gas heating temperature is 250°C, and the incident angle is 90°. The printing nozzle sprays perpendicular to the direction of the substrate, and the spraying distance moves in accordance with the growth direction to realize the additive manufacturing of amorphous pure aluminum. In this example, the structure of the prepared bulk material has the characteristics of an amorphous structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com