Moulds and methods for forming blanks of worm shafts rolled with roller wedge laterally

A technology for forming molds and worm shafts, applied in the direction of rolls, metal rolling, manufacturing tools, etc., can solve the problems of waste of materials, low efficiency, and high production costs, and achieve the effects of reducing processing procedures, reducing production costs, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

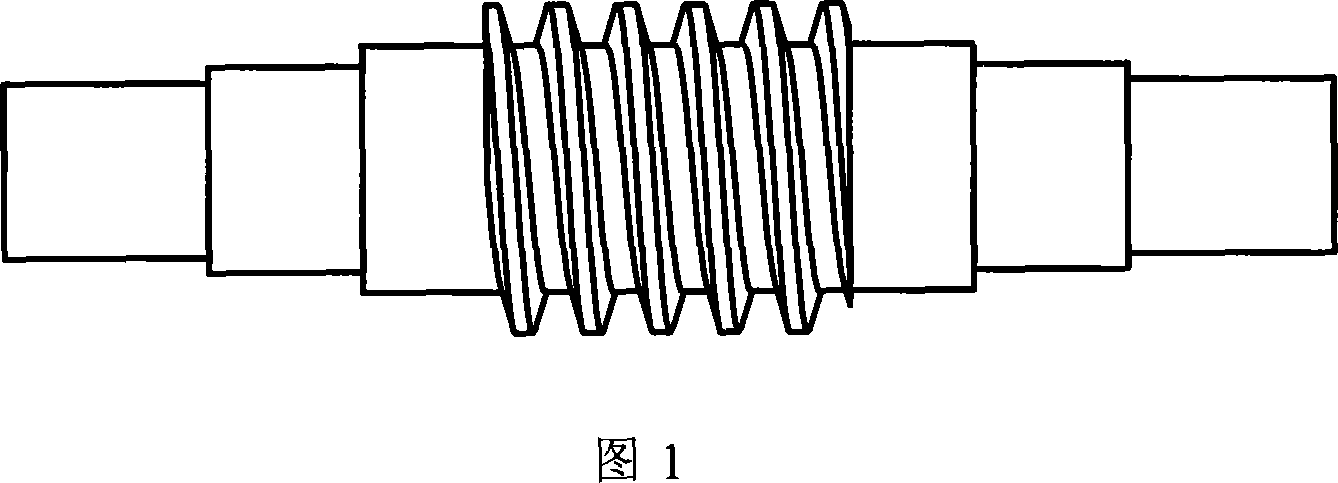

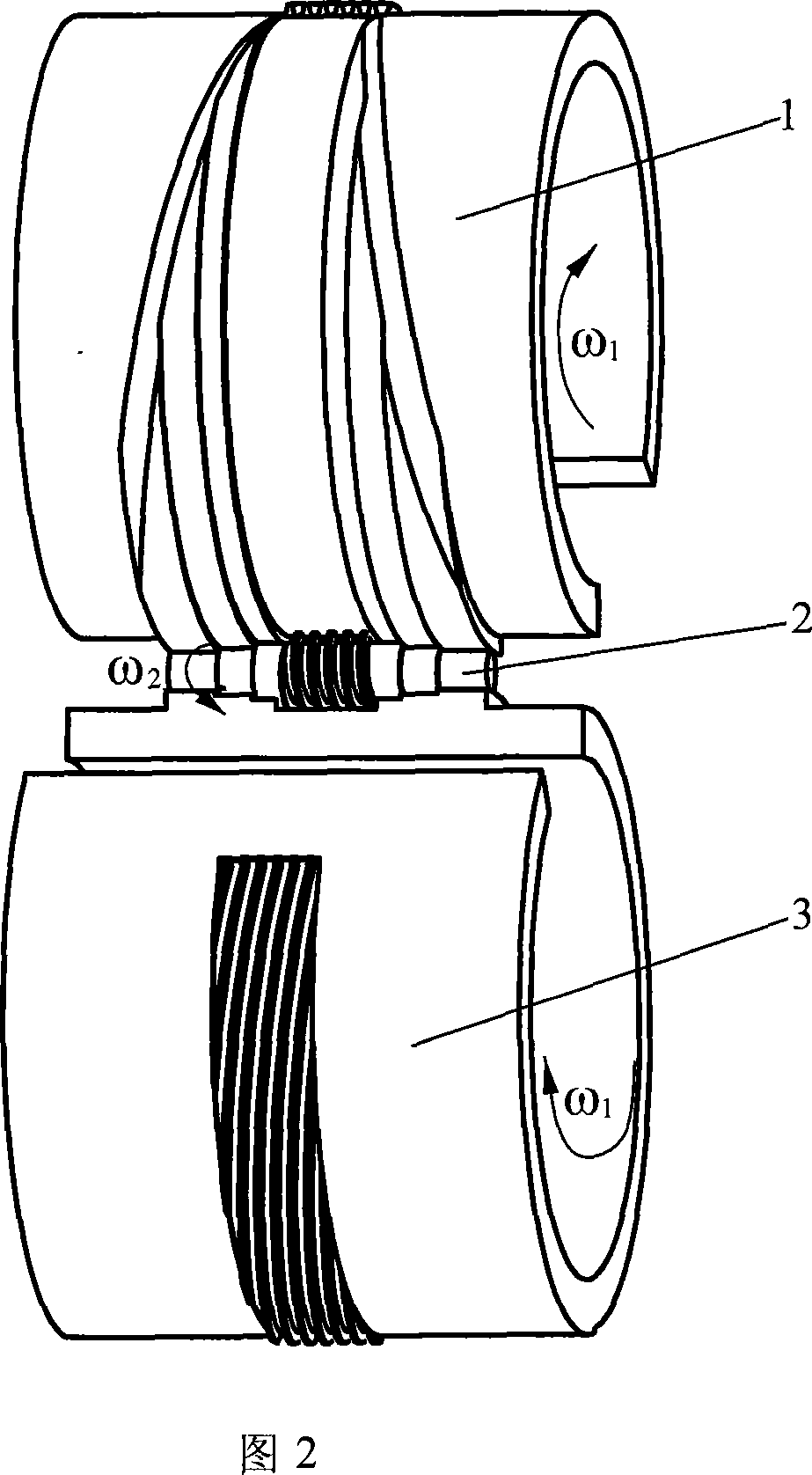

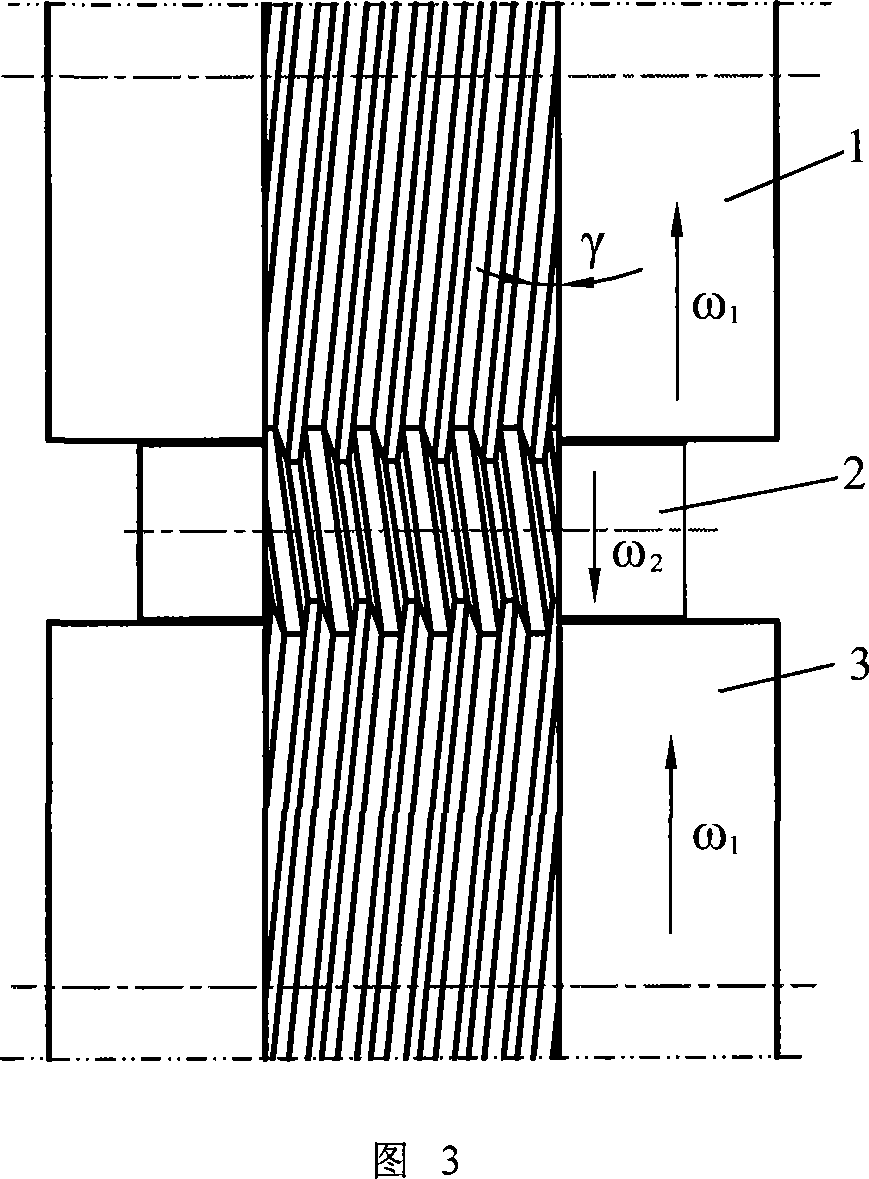

[0038] 1 to 20 are specific embodiments of the present invention.

[0039] First cut the round bar with a diameter of 58mm into 260mm long, then heat the bar to 1100~1150C in the medium frequency induction heating furnace, and send it into the cross wedge rolling mill through the feeding device, as shown in Figure 2, and install it on the rolling mill The upper mold 1 and the lower mold 3 with cavities on the two surfaces rotate in the same direction, and the heated metal circular bar 2 rotates in the opposite direction under the action of the mold to realize continuous radial compression and axial extension deformation. The spiral tooth-shaped part in the middle of the worm shaft blank is made, and then the stepped shaft parts at both ends of the worm shaft are gradually formed. One worm shaft blank is produced per roll revolution (Fig. 11). Forming example The helix angle of the upper and lower molds of the worm shaft blank is γ=4.75°, the rising angle of the top surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com