Titanium-aluminium alloy blisk and manufacturing method thereof

An integral blisk, titanium-aluminum alloy technology, applied in mechanical equipment, liquid fuel engines, components of pumping devices for elastic fluids, etc., can solve problems such as difficult control, welding cracks, large residual stress, etc., and achieve residual The effect of small stress, reducing technical difficulty and improving connection quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The preparation process is specifically:

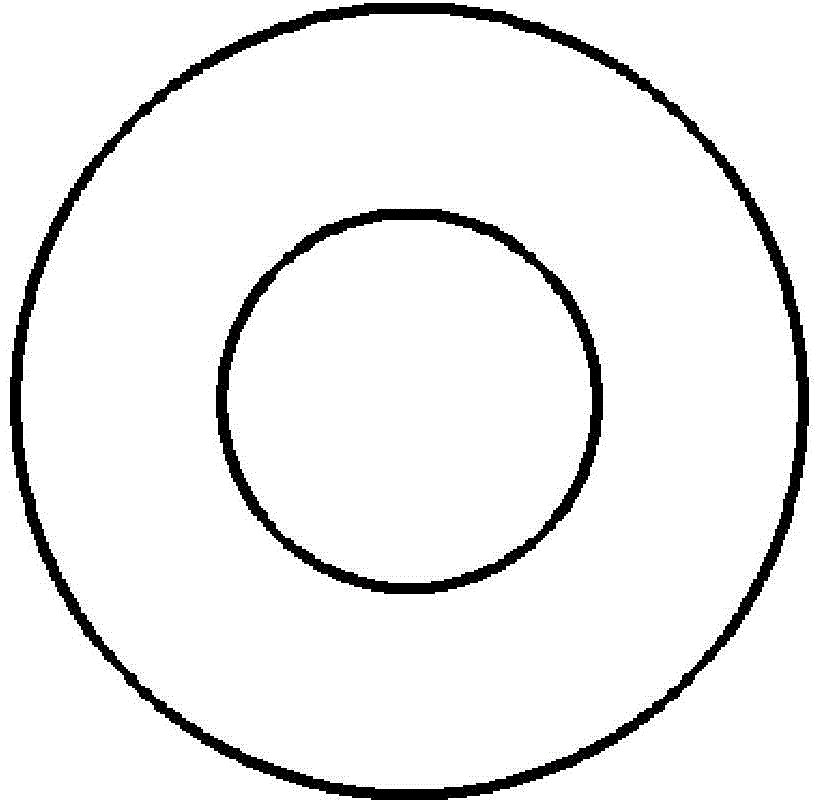

[0057] (1) The Ti of the overall blisk is forged by precision forging 2 AlNb disk-shaped parts, the shape is processed by CNC, such as figure 1 shown;

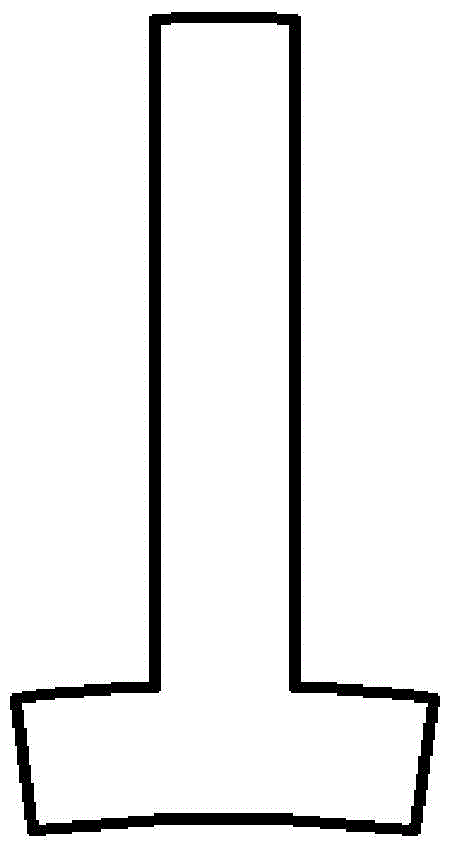

[0058] (2) The TiAl blades of the overall blisk are forged by the method of precision forging, and the shape is processed by numerical control, such as figure 2 shown;

[0059] (3) The method of chemical washing is used to treat Ti 2 The surface of the AlNb disc and TiAl blade is treated to remove the scale and dirt on the surface;

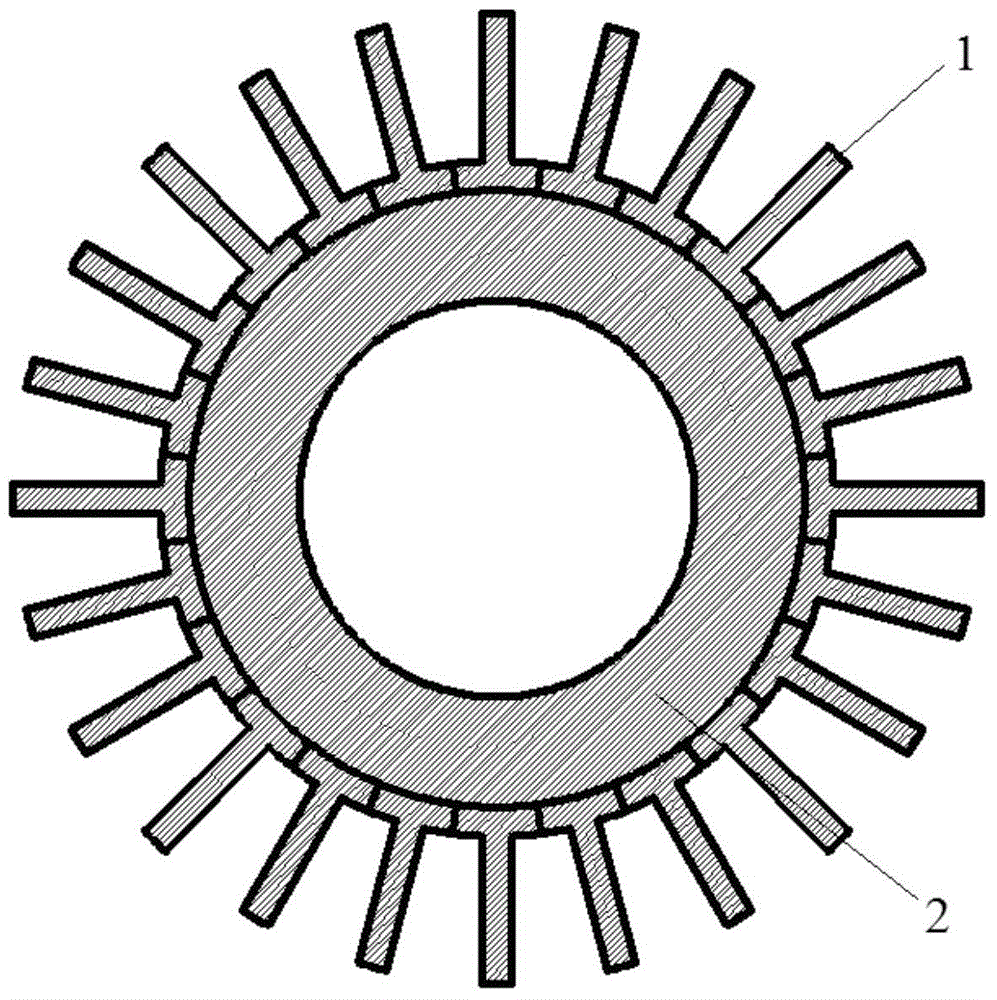

[0060] (4) Put Ti 2 The AlNb disk and TiAl blade are combined together, as shown in Figure 3(a), put into the cold spray equipment, and a layer of TC4 sheath is coated on the outer surface of the combined blade and disk, in which the cold Spraying process parameters: the preheating temperature is 500°C, the material acceleration is 800m / s, and the spraying distance is 10mm. The spraying sheath is a TC4 alloy casing with a thickness of about...

Embodiment 2

[0064] The preparation process is specifically:

[0065] (1) The TiAl disk-shaped piece of the overall blisk is forged by precision forging, and the shape is processed by numerical control, such as figure 1 shown;

[0066] (2) The TiAl blades of the overall blisk are forged by the method of precision forging, and the shape is processed by numerical control, such as figure 2 shown;

[0067] (3) adopt the method for chemical cleaning to treat the surface of TiAl disk and TiAl blade, remove surface oxide skin and dirt;

[0068] (4) Combine the TiAl disk and TiAl blade, as shown in Figure 3(a), put it into the electron beam forming equipment, and coat a layer of Q235 on the outer surface of the combined blade and disk Sheath, wherein the welding speed is 100mm / min, the angle is 50°, and the wire feeding speed is 160cm / min. The sheath of the electron beam forming is a Q235 sheath with a thickness of about 1mm that covers the blade and the disk. This shell wraps the blade and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com