Internal air injection discharging double-roller granulator

A granulator and granulation technology, applied in the direction of die extrusion granulation, etc., can solve the problems affecting granulation efficiency and granulation quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

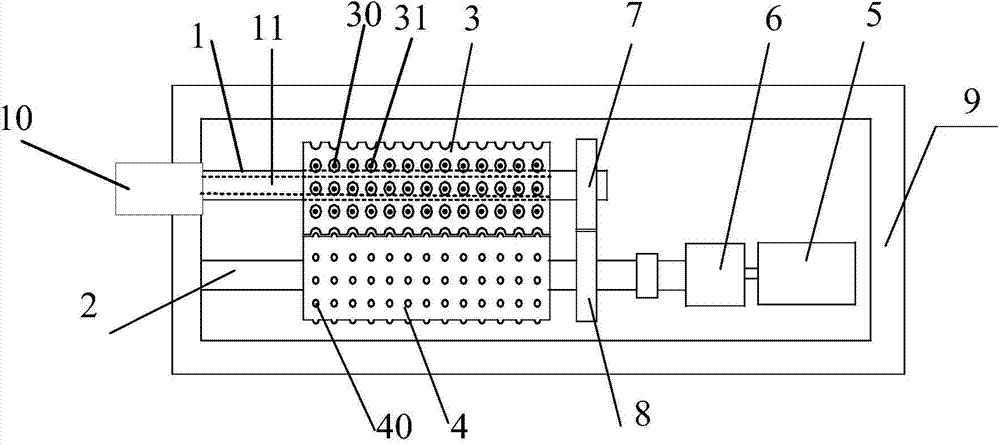

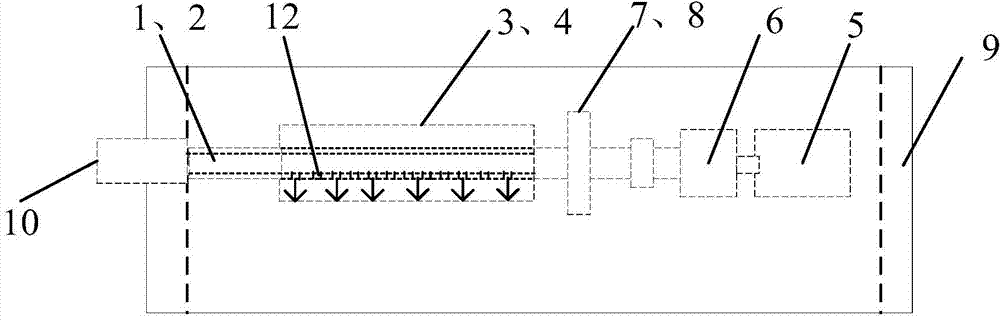

[0024] Such as figure 1 and figure 2 as shown, figure 1 It is a top view of a kind of internal jet unloading roller granulator proposed by the present invention; figure 2 It is a side view of an internal air-jet unloading double-roll granulator proposed by the present invention.

[0025] refer to figure 1 and figure 2 , a kind of internal jet unloading roller granulator that the present invention proposes, comprises: the first rotating shaft 1, the second rotating shaft 2, the first roller 3, the second roller 4 and power mechanism; The first rotating shaft 1 and the second rotating shaft The two rotating shafts 2 are arranged in parallel, the first roller 3 is fixed on the first rotating shaft 1, and the second roller 4 is fixed on the second rotating shaft 2; a plurality of grooves 30 are arranged on the outer surface of the first roller 3, and The outer surface of the second roller 4 is provided with a plurality of protrusions 40, the grooves 30 and the protrusions ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com