Indoor wall base bottom layer leveling mud with purification function and preparation and construction method

A construction method and functional technology, applied in construction, building structure, covering/lining, etc., can solve problems such as damage to surface decoration, bulging, indoor air pollution, etc., and achieve the effect of excellent construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

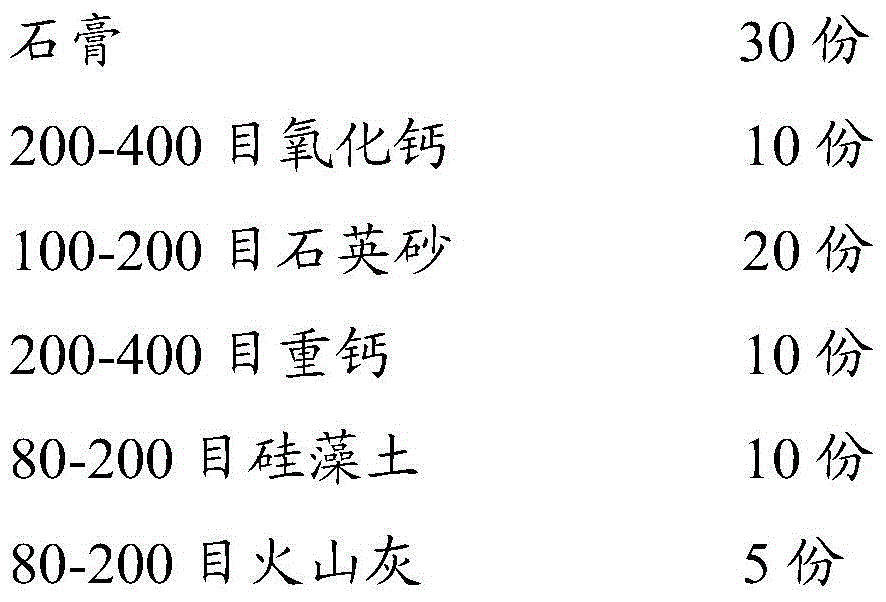

[0027] Prepare leveling mud by the following raw materials in parts by weight:

[0028] Gypsum 20kg, 200-400 mesh calcium oxide 5kg, 100-200 mesh quartz sand 50kg, 200-400 mesh heavy calcium 10kg, 80-200 mesh diatomite 10kg, 80-200 mesh volcanic ash 5kg, 100-200 mesh non-calcined Diatomite 5kg, 100-200 mesh attapulgite 1kg, 200-800 mesh magnesium aluminum silicate 1kg, 10-30nm nano-zinc oxide 0.5kg, 10-30nm nano-titanium dioxide 0.5kg, 300-1250 mesh kaolin 1kg, Pengrun Mix 5 kg of soil, 0.1 kg of citric acid, 0.9 kg of guar gum, 0.8 kg of alginate and 0.5 kg of hydroxymethyl cellulose, and stir evenly to obtain the described leveling mud with purification function.

Embodiment 2

[0030] Prepare leveling mud by the following raw materials in parts by weight:

[0031] Gypsum 50kg, 200-400 mesh calcium oxide 5kg, 100-200 mesh quartz sand 20kg, 200-400 mesh heavy calcium 10kg, 80-200 mesh diatomite 20kg, 80-200 mesh volcanic ash 10kg, 100-200 mesh non-calcined Diatomite 5kg, 100-200 mesh attapulgite 10kg, 200-800 mesh magnesium aluminum silicate 5kg, 10-30nm nano-zinc oxide 10kg, 10-30nm nano-titanium dioxide 0.5kg, 300-1250 mesh kaolin 10kg, bentonite 5kg, citric acid 0.5kg, guar gum 0.3kg, seaweed gum 4kg and hydroxymethyl cellulose 0.5kg are mixed, stir evenly, promptly obtain described leveling mud with purifying function.

Embodiment 3

[0033] Prepare leveling mud by the following raw materials in parts by weight:

[0034] Gypsum 30kg, 200-400 mesh calcium oxide 10kg, 100-200 mesh quartz sand 20kg, 200-400 mesh heavy calcium 30kg, 80-200 mesh diatomite 30kg, 80-200 mesh volcanic ash 6kg, 100-200 mesh non-calcined Diatomite 20kg, 100-200 mesh attapulgite 5kg, 200-800 mesh magnesium aluminum silicate 10kg, 10-30nm nano-zinc oxide 0.5kg, 10-30nm nano-titanium dioxide 10kg, 300-1250 mesh kaolin 5kg, bentonite 10kg, 0.5kg of citric acid, 0.3kg of guar gum, 0.8kg of seaweed gum and 5kg of hydroxymethyl cellulose were mixed, stirred evenly, and the described leveling mud with purification function was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com