High molecular polymer material having anti-bacterial and trace element slow release functions and preparation method thereof

A high-molecular polymer and trace element technology, which is applied in the field of high-molecular polymers containing metal ions and iodine at the same time, can solve the problems of poor taste, lack of trace elements, secondary pollution of microorganisms, etc. The effect of slow release of trace elements in rapid antibacterial disinfection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

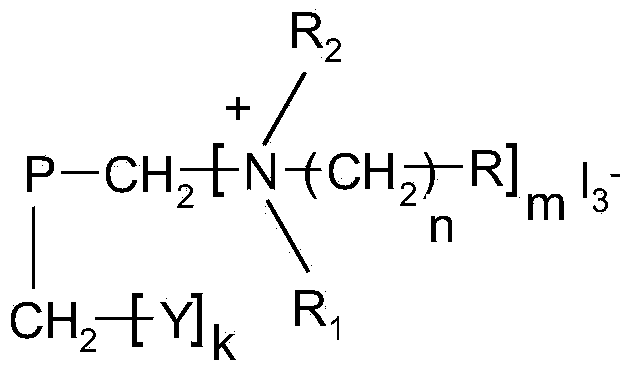

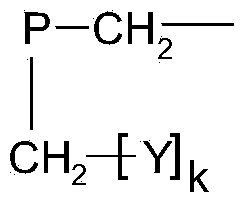

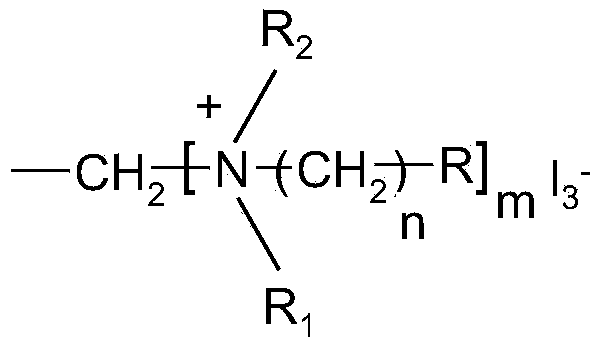

Image

Examples

Embodiment 1

[0029] This embodiment is the preparation of 1-dimethylaminomethyl-5,5-dimethylhydantoin, and its reaction formula is as follows:

[0030]

[0031] Weigh 5.84 g (0.037 mol) of 1-hydroxymethyl-5,5-dimethylhydantoin and place it in a 250 ml round-bottomed flask, add 30 ml of isopropanol to dissolve, and add dropwise a mass fraction of 33 5.05 g (0.037 mol) of dimethylamine solution, stirred and reacted at 40°C for 4 hours, and unreacted dimethylamine and solvent were distilled off under reduced pressure to obtain 7.37 g of a white solid product. Take 2.00 grams of white solid product, add an appropriate amount of anhydrous acetone until it is completely dissolved, and then pass through dry hydrogen chloride gas, there is a large amount of solid that is 1-dimethylaminomethyl-5,5-dimethylhydantoin The hydrochloride was precipitated, centrifuged, and dried to obtain 1.94 g. The dried 1-dimethylaminomethyl-5,5-dimethylhydantoin hydrochloride was dissolved in absolute ethanol, an...

Embodiment 2

[0033] This example is the preparation of p-vinylphenylmethylene-(5,5-dimethylhydantoin-1)methyl-dimethylammonium hydrochloride polymer macroporous cross-linked resin, which The reaction formula is as follows:

[0034]

[0035] Add 7.37 g of 1-dimethylaminomethyl-5,5-dimethylhydantoin obtained in Example 1 into a 250 ml round-bottomed flask and dissolve it with 30 ml of methanol, add macroporous cross-linked poly-p-chloro 2.82 g of methyl styrene resin was stirred and reacted at 60° C. for 16 hours. After the reaction, filter to obtain p-vinylphenylmethylene-(5,5-dimethylhydantoin-1)methyl-dimethylammonium hydrochloride polymer macroporous cross-linked resin, wash with water 6 times, and then dried at 45°C to constant weight to obtain 4.88 g of the product. Elemental analysis test values: C, 62.21; H, 7.483; N, 9.15. IR: 3425, 2348, 1787, 1733, 1614, 1513, 1476, 1433, 1379, 1293, 1222, 1105, 1013, 915, 857, 778, 747, 706, 631, 601cm -1 .

Embodiment 3

[0037] This embodiment is the immobilized Zn 2+ To p-vinylphenylmethylene-(5,5-dimethylhydantoin-1)methyl-dimethylammonium hydrochloride polymer macroporous cross-linked resin, the reaction process is as follows:

[0038] Weigh 5.00 g of p-vinylphenylmethylene-(5,5-dimethylhydantoin-1) methyl-dimethylammonium hydrochloride polymer macroporous cross-linking resin and place in 250 Add 100 ml of 0.10 mol / L sodium hydroxide solution into a beaker with 1000 ml, and slowly stir the reaction at room temperature for 1 hour, filter under reduced pressure to remove unreacted sodium hydroxide, wash it with deionized water for 5 times, and put it under 80 °C Dry to constant weight. Take 1.00 g of sodium hydroxide-treated resin, add it to 100 ml of 0.05 mol / L zinc chloride solution, stir slowly at room temperature for 1 hour, then filter under reduced pressure to remove unreacted zinc chloride, and use deionized Water was washed 5 times again, and dried to constant weight at 80°C to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com