Bi-component epoxy adhesive and preparation method thereof

An epoxy adhesive, two-component technology, used in adhesives, epoxy resin adhesives, carboxyl rubber adhesives, etc. The effect of good connection, good adhesion and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Two-component epoxy adhesive of the present invention comprises A component and B component, and described A component is made up of following components by weight:

[0037] Modified bisphenol A epoxy resin 30

[0038] Fluorenyl epoxy resin 20

[0039] Hyne Epoxy 15

[0040] The B component consists of the following components in parts by weight:

[0041] Maleic anhydride and endomethylenetetrahydrophthalic anhydride in a 4:3 mixture 20.

[0042] Preparation:

[0043] A, prepare modified bisphenol A epoxy resin

[0044] Under the condition of nitrogen protection, heat 100 parts by weight of bisphenol A type epoxy resin and 1 part by weight of liquid carboxyl-terminated nitrile rubber to 85 °C according to the above ratio to mix the two evenly, add 15 parts by weight of dicyandiamide, stir, Simultaneously vacuumize and react for 0.5 hours; keep warm for 4 hours at 130°C;

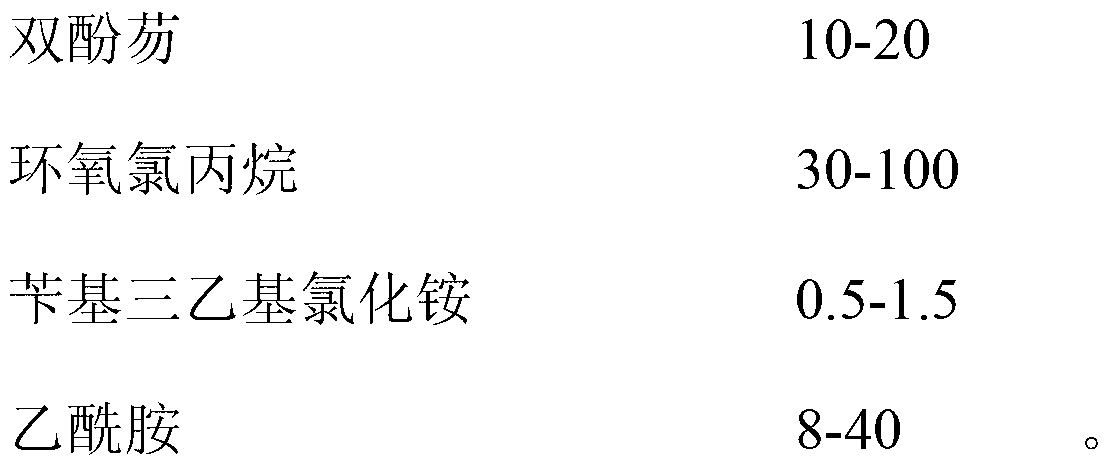

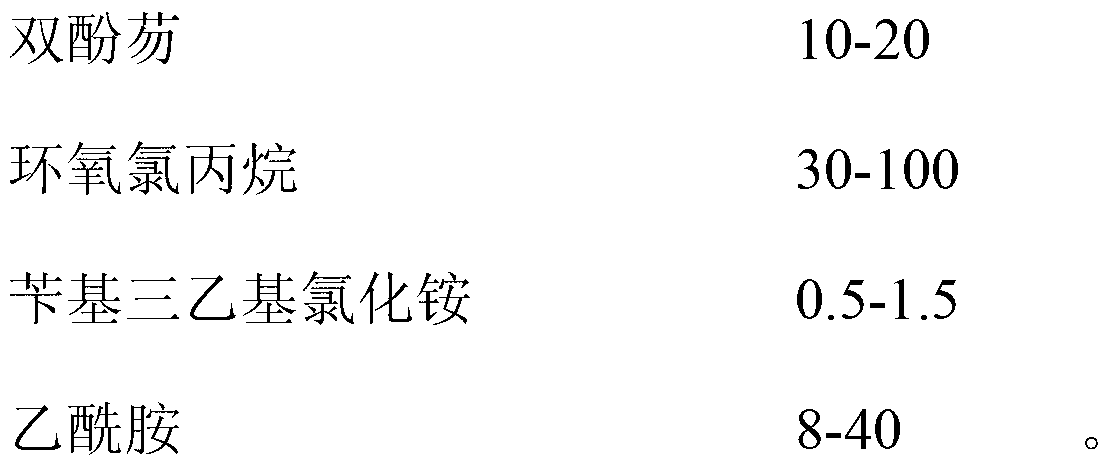

[0045] B. Preparation of fluorenyl epoxy resin

[0046] Add 10 parts by weight of bisphenol ...

Embodiment 2

[0050] Two-component epoxy adhesive of the present invention comprises A component and B component, and described A component is made up of following components by weight:

[0051] Modified bisphenol A epoxy resin 30

[0052] Fluorenyl epoxy resin 70

[0053] Hein Epoxy 50

[0054] The B component consists of the following components in parts by weight:

[0055] A 4:3 mixture of maleic anhydride and endomethylene tetrahydrophthalic anhydride 150.

[0056] Preparation:

[0057] A, prepare modified bisphenol A epoxy resin

[0058] Under the condition of nitrogen protection, heat 100 parts by weight of bisphenol A epoxy resin and 8 parts by weight of liquid-terminated carboxylated nitrile rubber to 120 °C according to the above ratio to mix the two evenly, add 30 parts by weight of dicyandiamide, stir, Simultaneously vacuumize and react for 1.5 hours; keep warm for 4 hours at 160°C;

[0059] B. Preparation of fluorenyl epoxy resin

[0060] Add 20 parts by weight of bisphen...

Embodiment 3

[0064] Two-component epoxy adhesive of the present invention comprises A component and B component, and described A component is made up of following components by weight:

[0065] Modified bisphenol A epoxy resin 60

[0066] Fluorenyl epoxy resin 20

[0067] Hyne Epoxy 15

[0068] The B component consists of the following components in parts by weight:

[0069] A 4:3 mixture of maleic anhydride and endomethylenetetrahydrophthalic anhydride 90.

[0070] Preparation:

[0071] A, prepare modified bisphenol A epoxy resin

[0072]Under the condition of nitrogen protection, heat 100 parts by weight of bisphenol A type epoxy resin and 3 parts by weight of liquid carboxylated nitrile rubber to 90°C according to the above ratio to mix the two evenly, add 18 parts by weight of dicyandiamide, stir, Simultaneously vacuumize and react for 1 hour; keep warm for 4 hours at 140°C;

[0073] B. Preparation of fluorenyl epoxy resin

[0074] Add 15 parts by weight of bisphenol fluorene an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com