Glufosinate-ammonium dispersible oil suspension and preparation method therefor

A technology of glufosinate-ammonium and dispersing oil, which is applied in the field of pesticides, can solve the problems of high component matching requirements, difficult emulsification, high volatility, etc., and achieve good heat storage stability and low temperature stability, resistance to rain erosion, and long-lasting effect long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

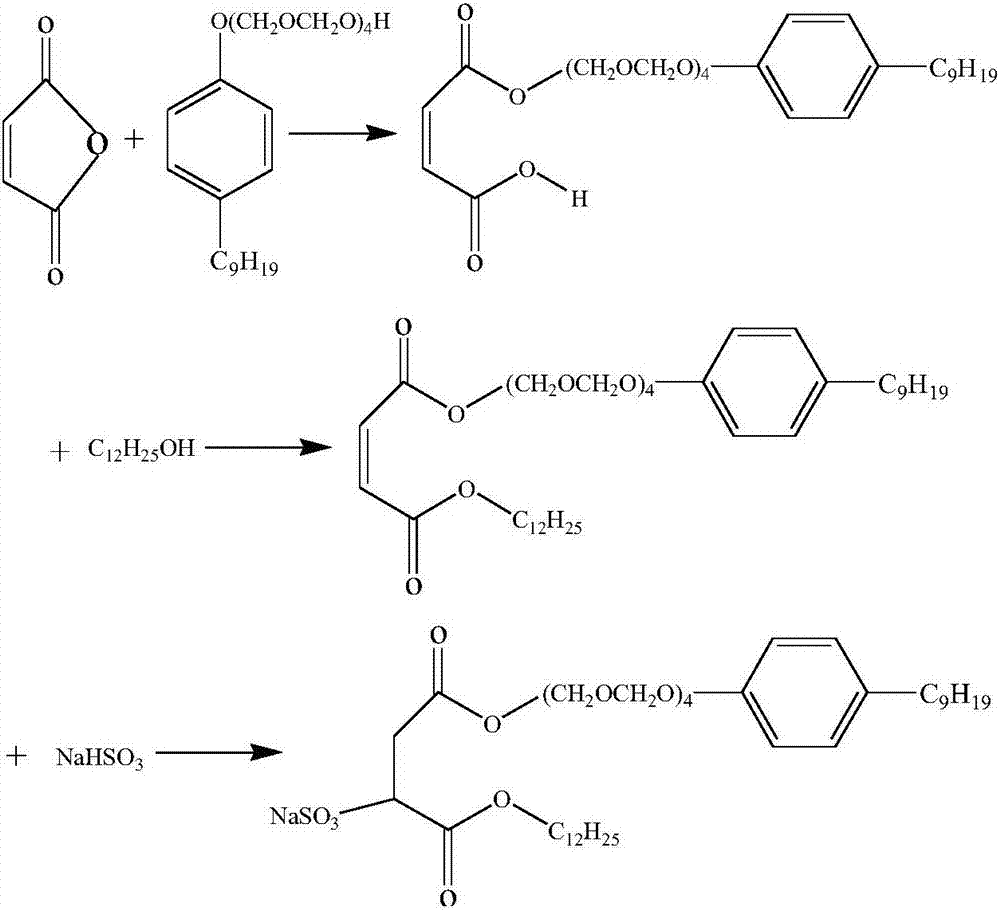

Method used

Image

Examples

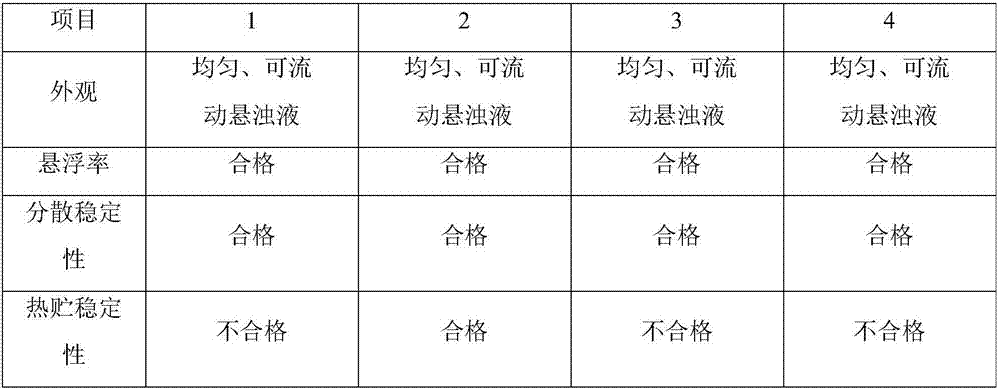

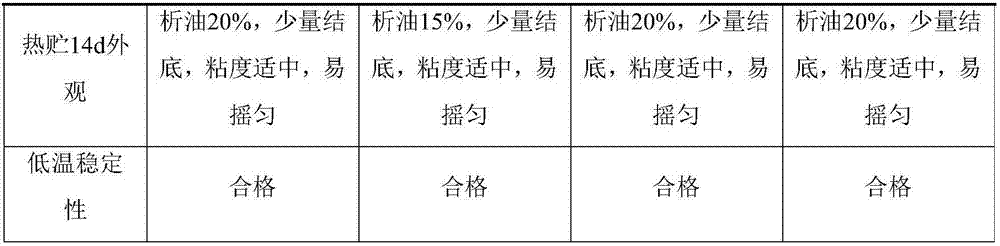

Embodiment 1

[0020] A glufosinate-ammonium dispersible oil suspension concentrate is composed of the following substances in weight percent: glufosinate-ammonium 15%, emulsifier 12%, wetting and dispersing agent 3%, thixotropic agent 4%, and the balance is dispersion medium.

[0021] 4% triphenylethylphenol polyoxyethylene ether, 4% propylene glycol polyoxyethylene polyoxypropylene block polymer, 4% calcium dodecylbenzenesulfonate, 3% alkylphenol polyoxyethylene ether carboxylate , 20% solvent oil, and the remaining amount of methyl oleate are mixed and dispersed evenly; add 15% glufosinate-ammonium technical material; add 3.5% fumed silica, 0.5% organic bentonite, stir and mix and perform high-speed shearing; Carry out sand grinding, grinding for 1-2h, the particle size D90 is below 5 microns.

Embodiment 2

[0023] A glufosinate-ammonium dispersible oil suspension concentrate is composed of the following substances in weight percent: glufosinate-ammonium 15%, emulsifier 12%, wetting and dispersing agent 3%, thixotropic agent 4%, and the balance is dispersion medium.

[0024] 3% alkylphenol polyoxyethylene ether formaldehyde condensate, 4% tristyrylphenol polyoxyethylene ether, 5% calcium dodecylbenzenesulfonate, 3% dispersant A and 20% epoxy soybean oil, The remaining amount of methyl oleate was mixed and dispersed evenly; 15% glufosinate-ammonium technical material was added; 3.5% fumed silica and 0.5% organic bentonite were added; after stirring and mixing, high-speed shearing was carried out; -2h, the particle size D90 is below 5 microns.

Embodiment 3

[0026] A glufosinate-ammonium dispersible oil suspension concentrate is composed of the following substances in weight percentage: glufosinate-ammonium 18%, emulsifier 12%, wetting and dispersing agent 3%, thixotropic agent 4%, and the balance is dispersion medium.

[0027] 4% triphenylethylphenol polyoxyethylene ether, 4% alkylphenol polyoxyethylene ether formaldehyde condensate, 4% calcium dodecylbenzenesulfonate, 3% sodium isooctyl maleate sulfonate Mix with methyl oleate and disperse evenly; add 18% glufosinate-ammonium technical material; add 3.5% fumed silica, 0.5% organic bentonite, stir and mix and perform high-speed shearing; perform sand milling under grinding media, and grind for 1- 2h, the particle size D90 is below 5 microns.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com