Preparation process of stearate

A technology of stearate and preparation technology, applied in the field of preparation technology of stearate, can solve the problems of affecting the performance of plastic products, difficulty in controlling its wetness, unstable production process, etc., saving reaction time and eliminating caustic soda , The effect of uniform product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A kind of preparation technology of zinc stearate, described technology specifically comprises the steps:

[0041] (1) Weigh 500kg of stearic acid and 75.5kg of zinc oxide, the metal compound is ground and passed through a 200-mesh screen, then stearic acid and zinc oxide are added to the reaction kettle in turn, and then 0.86kg of benzoic acid is added.

[0042] (2) Fill the inside of the reaction kettle in step (1) with an inert gas to pressurize to 0.6 MPa, then stir and heat up to 80° C., and react for 4 hours to obtain zinc stearate coarse powder.

[0043] (3) the zinc stearate coarse powder that step (2) obtains is pulverized, finally obtains zinc stearate white powder.

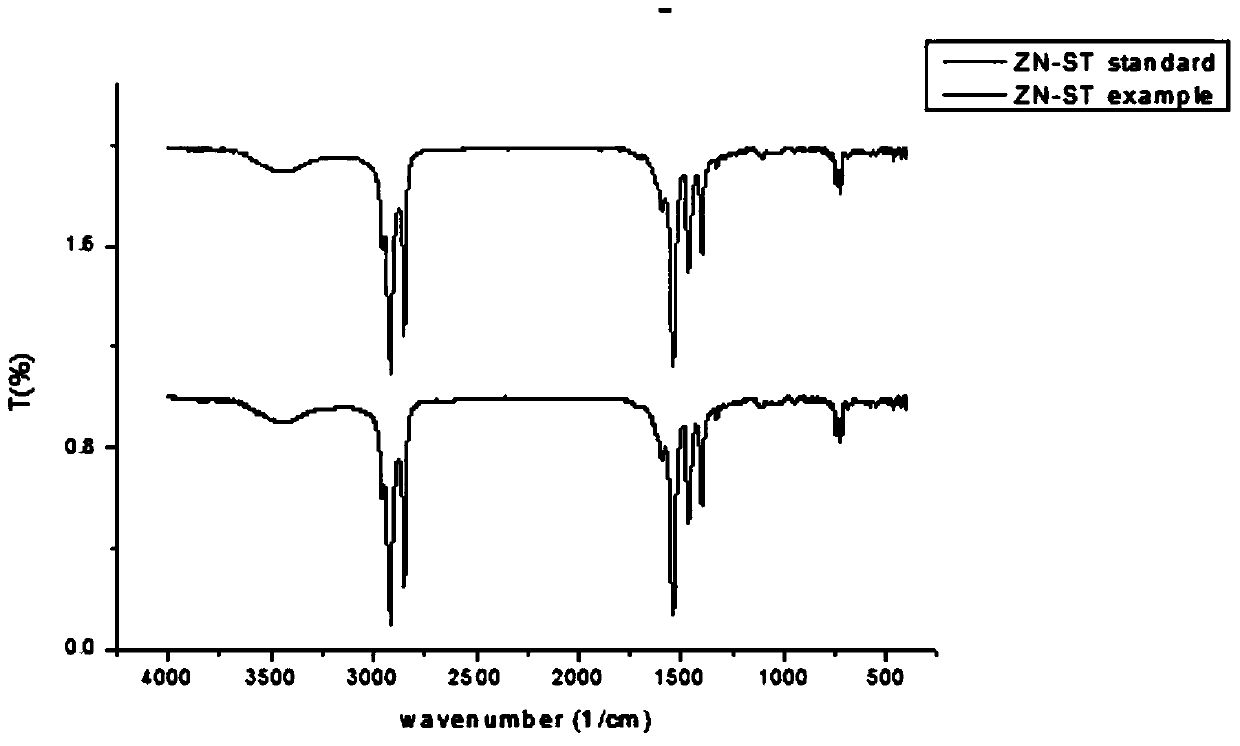

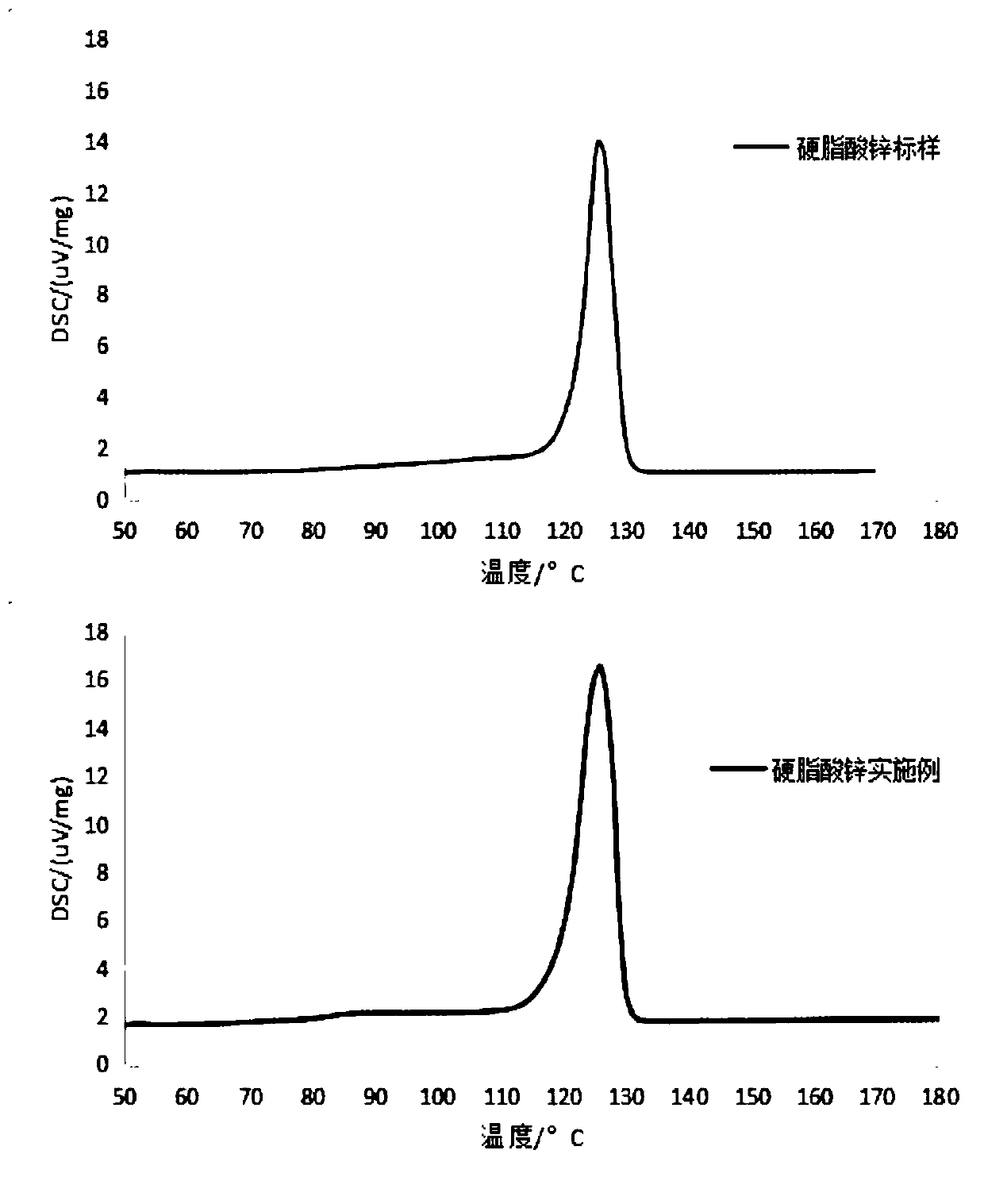

[0044] (4) Using a differential scanning calorimeter to analyze the purity of the powder product obtained in step (3).

[0045] Table 1 is zinc stearate product detection analysis result among the present invention.

[0046] Table 1:

[0047] Test items standard value test value ...

Embodiment 2

[0049] A kind of preparation technology of magnesium stearate, described technology specifically comprises the steps:

[0050] (1) Weigh 500kg of stearic acid and 31.5kg of magnesium oxide, the metal compound is ground and passed through a 200-mesh sieve, then the stearic acid and zinc oxide are added to the reaction kettle in turn, and then 0.53kg of water is added.

[0051] (2) Fill the inside of the reactor in step (1) with an inert gas and pressurize to 0.55 MPa, then stir and heat up to 80° C., and react for 4.5 hours to obtain magnesium stearate coarse powder.

[0052] (3) The magnesium stearate coarse powder obtained in step (2) is pulverized to finally obtain the magnesium stearate white powder product.

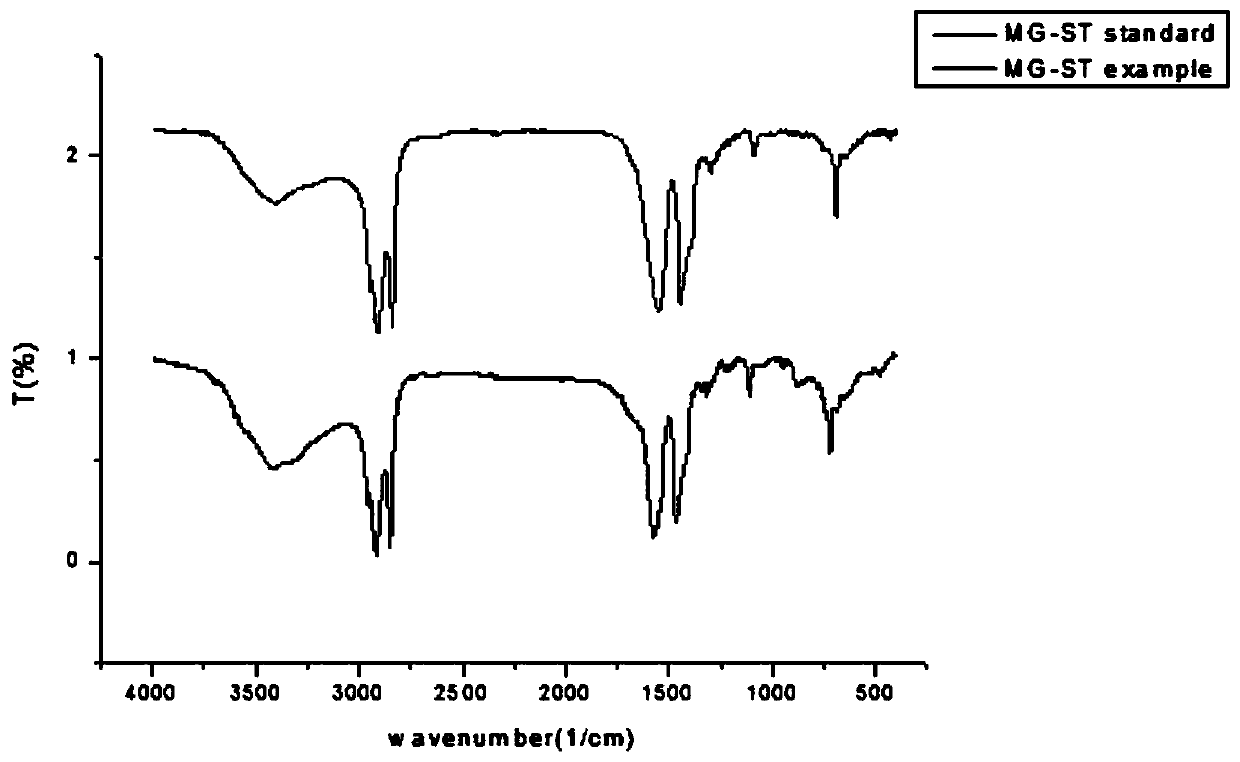

[0053] (4) Using a differential scanning calorimeter to analyze the purity of the powder product obtained in step (3).

Embodiment 3

[0055] A kind of preparation technology of magnesium stearate, described technology specifically comprises the steps:

[0056] (1) Weigh 500kg of stearic acid and 61kg of magnesium hydroxide, grind the metal compound and pass through a 200-mesh sieve, then add stearic acid and zinc oxide into the reaction kettle successively, and then add 0.82kg of maleic anhydride.

[0057] (2) Fill the inside of the reactor in step (1) with an inert gas to pressurize to 0.5 MPa, then stir and heat up to 65° C., and react for 5 hours to obtain coarse magnesium stearate powder.

[0058] (3) The magnesium stearate coarse powder obtained in step (2) is pulverized to finally obtain the magnesium stearate white powder product.

[0059] (4) Use a differential scanning calorimeter to detect the powder product obtained in step (3) for analysis.

[0060] Table 2 is the detection analysis result of magnesium stearate product among the present invention.

[0061] Table 2: Standard values: melting poin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com