Method for producing high-strength high-modules carbon fibre and special equipment thereof

A high-modulus carbon fiber and production method technology, which is applied in the fields of fiber chemical characteristics, textiles and papermaking, microwave heating, etc., can solve problems such as unguaranteed strength, uneven product quality, and fluctuations in carbon fiber heating temperature, and achieve reaction temperature control Sensitive, accelerated graphitization process, uniform product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

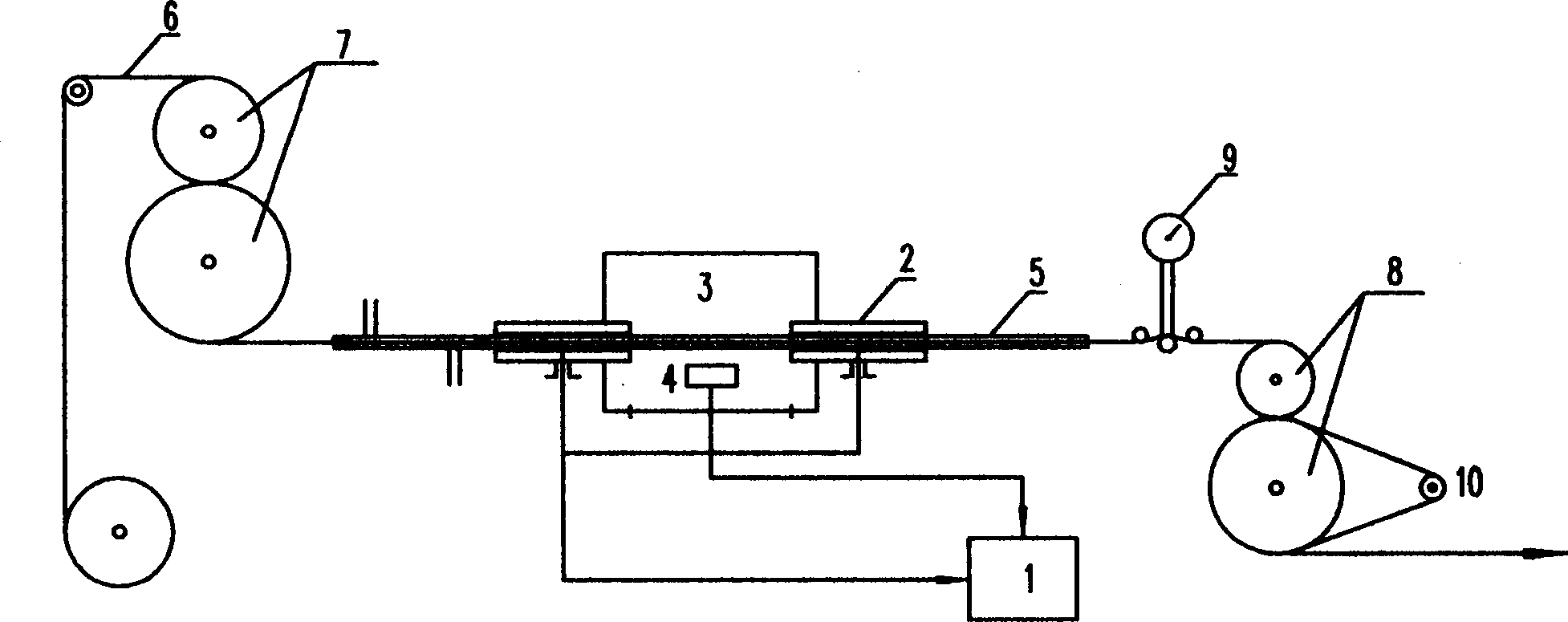

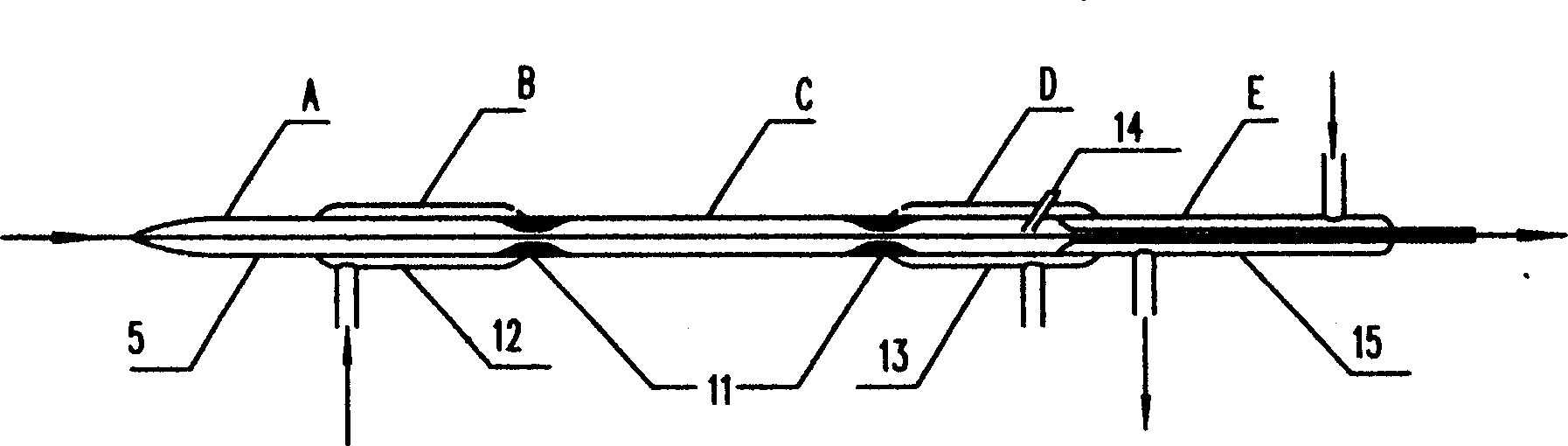

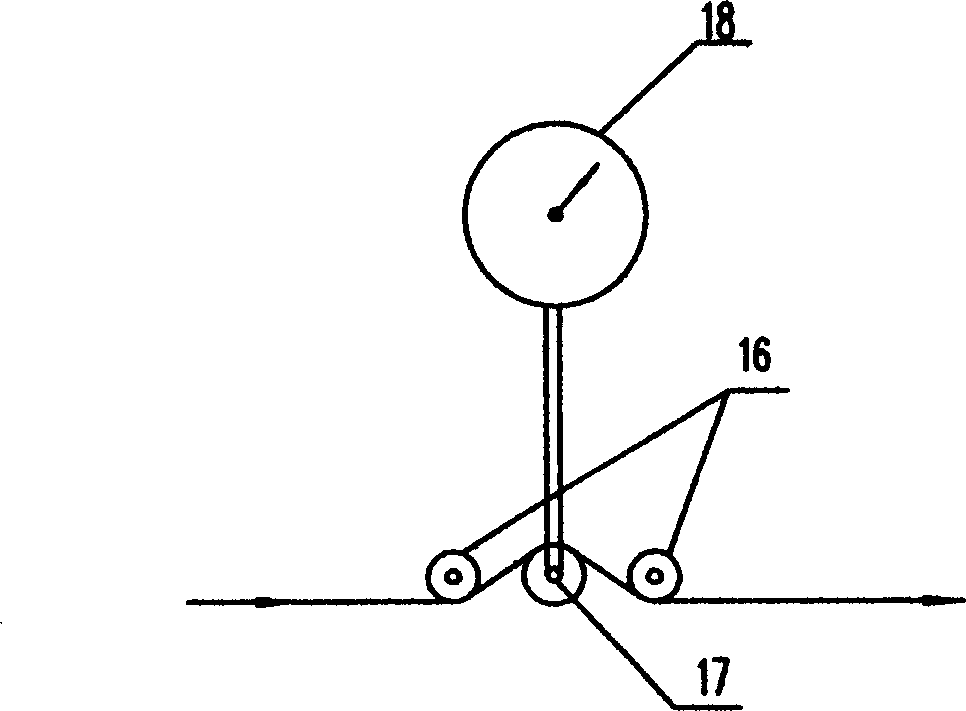

[0015] As shown in Figure 1 and Figure 2, the equipment for producing high-strength and high-modulus carbon fiber of the present invention is mainly composed of a high-frequency generator 1, a radio frequency coupler 2, a quartz reaction tube 5, and a drafting device 6, and its high-frequency heating reaction zone 3 is positioned In the resonant cavity of the RF coupler 2, the optical thermometer 4 is arranged outside the quartz reaction tube 5 in the high-frequency heating reaction zone, and its signal output terminal is connected with the input terminal of the high-frequency generator 1, and the optical temperature measurement device is used to The slight temperature change in the reaction tube is converted into an electrical signal and fed back to the high-frequency generator. The computer controls and continuously adjusts the output power of the high-frequency generator to realize the automatic control of the whole machine. It is easy to operate and accurate in temperature c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com