Combination technology for processing difficultly-degraded dye waste water

A combination process and dye wastewater technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., to achieve complete decolorization and deodorization treatment, simple operation, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with specific examples.

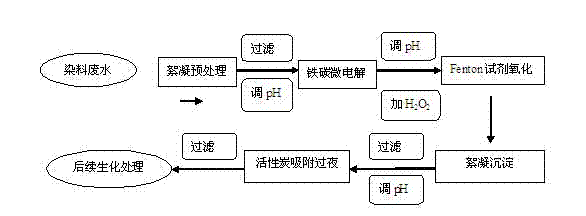

[0017] Wastewater from a dye factory contained about ten different types of dyes, including metal complex dyes. The color of the wastewater is dark brown red, exudes a foul smell, the COD is about 5000, and the chromaticity is about 3200. Using a single method such as micro-electrolysis, Fenton method, and catalytic degradation method has little effect on decolorization and deodorization. The waste water is treated by a combined process as shown in the accompanying drawing.

[0018] Firstly, add inorganic salts such as ammonium oxalate into the wastewater, stir and let it stand, a large amount of precipitation will be produced, and the color of the wastewater will become significantly lighter, from opaque dark brown red to transparent light brown, and the chromaticity will drop by 30-40%.

[0019] Add an iron-carbon mixture (the mass ratio of the two is 2:1) to the light bro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com