Inositol refining method

A refining method, the technology of inositol, applied in the field of inositol refining, can solve the problems of low utilization rate of mother liquor, low product quality, high production cost, etc., and achieve the effect of low production cost, high product quality and less inorganic salt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

[0016] A method for refining inositol, comprising the following steps:

[0017] Step 1: dissolving crude inositol in distilled water to prepare inositol solution, and then heating.

[0018] Step 2: adding activated carbon of 5% mass of crude inositol to the inositol solution to decolorize the inositol solution.

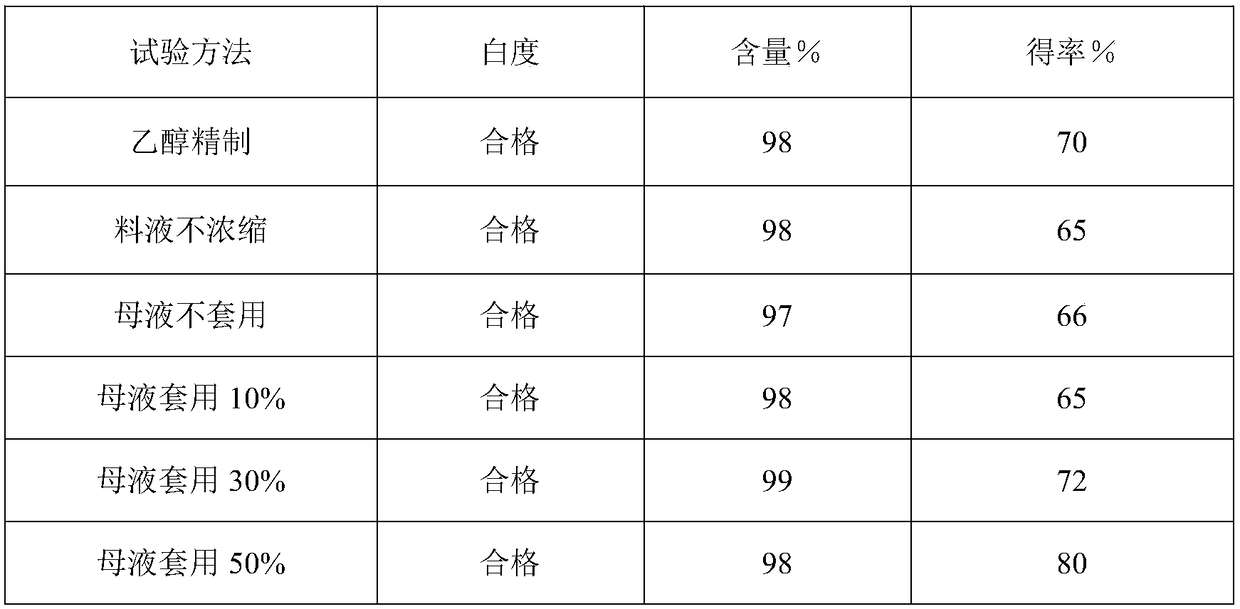

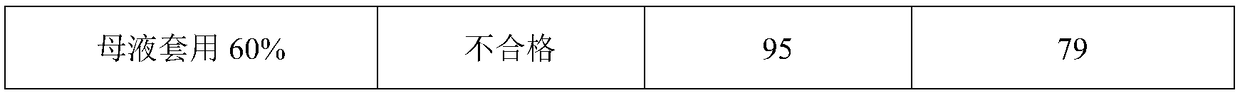

[0019] Step 3: Activated carbon is removed by negative pressure suction filtration at 90°C, concentrated and cooled to 25°C, crystallized, and then filtered to obtain a primary refined product of inositol; 50% of the refined mother liquor is reused, and the remaining 50% of the mother liquor is reused to The pre-evaporation purification section of the inositol solution, re-evaporating and crystallizing after purification, and extracting the crude inositol.

[0020] Step 4: Re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com