Complex printing and dyeing wastewater quality-divided treating and reusing integrated technology

A technology for the treatment of printing and dyeing wastewater and quality separation, which is applied in the textile industry wastewater treatment, multi-stage water treatment, water/sewage treatment and other directions, can solve the problems of unfavorable waste water treatment cost, consuming manpower and financial resources, and not implementing quality separation treatment, etc. Achieve the effect of reducing energy consumption, high reuse rate of reclaimed water, and low treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

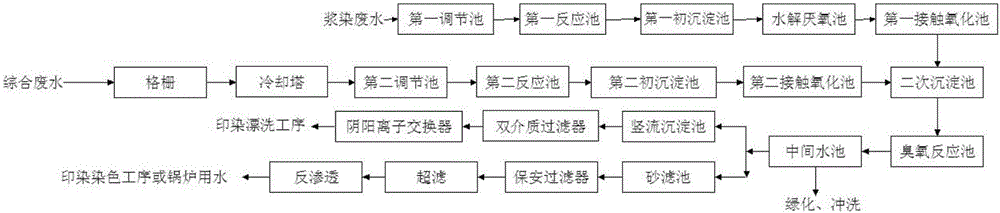

Image

Examples

Embodiment 1

[0043] The amount of highly polluted pulp dyeing wastewater with a COD of 1000mg / L and a chroma of 5000 times is 5000t; the water intake of comprehensive wastewater is 50000t with a COD of about 715mg / L and a chroma of 850 times. The highly polluted pulp dyeing wastewater is conditioned in the first regulating tank, and flocculated and decolorized in the first reaction tank, wherein the FeSO in the first reaction tank 4 The dosages of , PAM and quaternary ammonium polymer compounds were 1350mg / L, 9mg / L and 35mg / L respectively. After the first primary sedimentation tank settled (hydraulic retention time 3h), the COD dropped to 605mg / L, and the chroma reduced to 1852 times; after the reaction in the hydrolysis anaerobic tank, the COD dropped to 363mg / L, and the chroma dropped to 389 times (hydraulic retention time was 8h); after being degraded by the first contact oxidation tank, the COD dropped to 54mg / L, and the color The temperature is reduced to 206 times (the hydraulic rete...

Embodiment 2

[0048] The water intake of highly polluted pulp dyeing wastewater is 10,000t, the COD is about 2655mg / L, and the chroma is 9,000 times; the water intake of comprehensive wastewater is 40,000t, the COD is about 950mg / L, and the chroma is 1,000 times. Highly polluted wastewater is conditioned and tempered in the first regulating tank, and flocculated and decolorized in the first reaction tank, wherein the FeSO in the first reaction tank 4 The dosages of , PAM and quaternary ammonium polymer compounds were 1550mg / L, 13mg / L and 50mg / L respectively. After the first primary sedimentation tank settled (hydraulic retention time 3h), the COD dropped to 1290mg / L, and the chroma reduced to 2805 times; after the reaction in the hydrolysis anaerobic tank, the COD dropped to 768mg / L, and the chromaticity dropped to 626 times (the hydraulic retention time was 8h); after being degraded by the first contact oxidation tank, the COD dropped to 115mg / L, and the color The temperature is reduced to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com