Preparation method of high-purity plant source oligomerization galactose

A technology of galactooligosaccharides and plant sources, applied in the field of preparation of plant sources of galactooligosaccharides, can solve the problems of complex process, low purity of active ingredients, low extraction rate, etc., achieve high social benefits, simple and controllable fermentation process , The effect of high yield of active ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

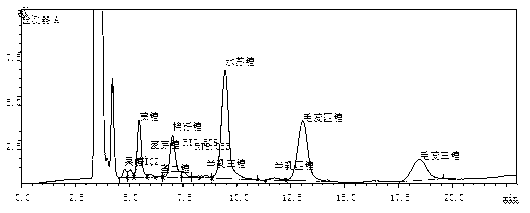

Embodiment 1

[0032] A preparation method of high-purity plant-derived galacto-oligosaccharides, comprising the following steps:

[0033] (1) Preparation of sugar solution: choose Zeilan as the raw material, wash the raw material, add water at 70°C for 1.5 hours according to the ratio of raw material to water mass ratio of 1:4, squeeze the juice; take the residue, add 2 times to Residue-quality water, extract at 70°C for 1.0h, squeeze the juice; mix the sugar liquid obtained from virgin pressing and re-pressing.

[0034] (2) Fermentation: Press the juice, yeast extract, MgSO 4 ·7H 2 O and KH 2 PO 4Mix, sterilize, cool to normal temperature, add activated fruit wine yeast to the mixed liquid at a ratio of 1 L: 2.0 g, incubate on a constant temperature shaker at 28°C for 10 hours, stop fermentation, and obtain a fermented liquid.

[0035] (3) Impurity removal: raise the temperature of the fermentation broth to 121°C, keep it for 15 minutes, filter, remove the precipitate, add the clarifyi...

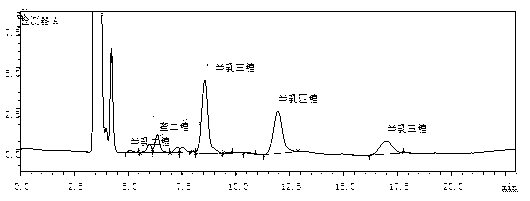

Embodiment 2

[0040] A preparation method of high-purity plant-derived galacto-oligosaccharides, comprising the following steps:

[0041] (1) Preparation of sugar solution: choose Salvia miltiorrhiza as the raw material, wash the raw material, add water to extract at 80°C for 1.0 h according to the ratio of raw material to water mass ratio of 1:6, and squeeze the juice; take the residue and add 1 times the residue Quality water, leached for 1.0h at 80°C, squeezed the juice; mixed the sugar liquid obtained from virgin pressing and re-pressing.

[0042] (2) Fermentation: According to the mass ratio of 1000:6:0.4:0.6, the squeezed juice, yeast extract, MgSO 4 ·7H 2 O and KH 2 PO 4 Mix, sterilize, cool to normal temperature, add activated fruit wine yeast to the mixed solution at a ratio of 1 L: 2.5 g, incubate in a constant temperature shaker at 30°C for 6 hours, stop fermentation, and obtain a fermentation broth.

[0043] (3) Impurity removal: raise the temperature of the fermentation bro...

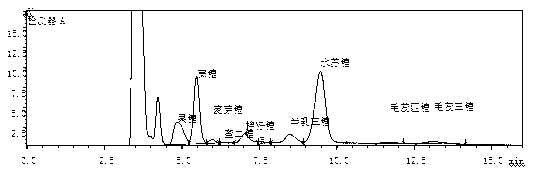

Embodiment 3

[0048] A preparation method of high-purity plant-derived galacto-oligosaccharides, comprising the following steps:

[0049] (1) Preparation of sugar liquid: collect soybean wastewater generated during the production of soybean products, concentrate it until the refraction is 8°Brix, and use it as the sugar liquid to be fermented.

[0050] (2) Fermentation: According to the mass ratio of 1000:4:0.2:0.8, the squeezed juice, yeast extract, MgSO 4 ·7H 2 O and KH 2 PO 4 Mix, sterilize, cool to normal temperature, add activated fruit wine yeast to the mixed solution at a ratio of 1L:0.5g, incubate on a constant temperature shaker at 32°C for 7 hours, stop fermentation, and obtain a fermentation broth.

[0051] (3) Impurity removal: raise the temperature of the fermentation broth to 115°C, keep it for 20 minutes, filter, remove the sediment, add the clarifier calcium hydroxide to the filtrate at a ratio of 8g:1L, wait until the precipitation is complete, take the supernatant liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com