Preparation method and application of stearic acid modified zero-valent iron composite material

A technology of composite materials and stearic acid, applied in the field of environmental chemistry, can solve the problems of hindering the contact of active ingredients, reducing the activity of zero-valent iron, and poor transmission, and achieve the effects of inhibiting cold welding, increasing fracturing rate, and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

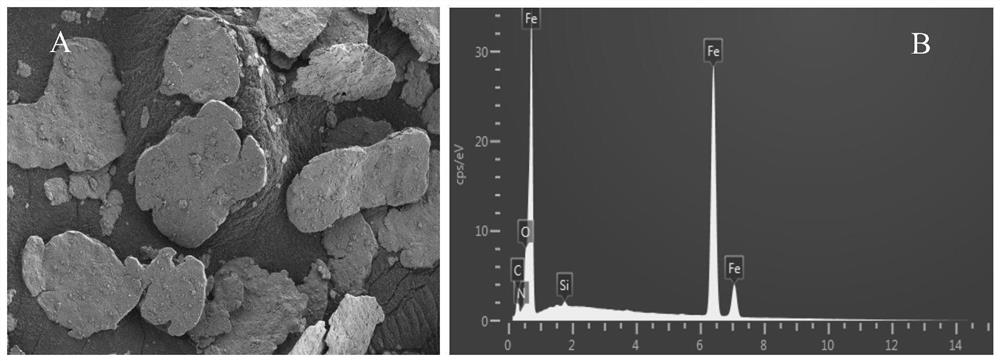

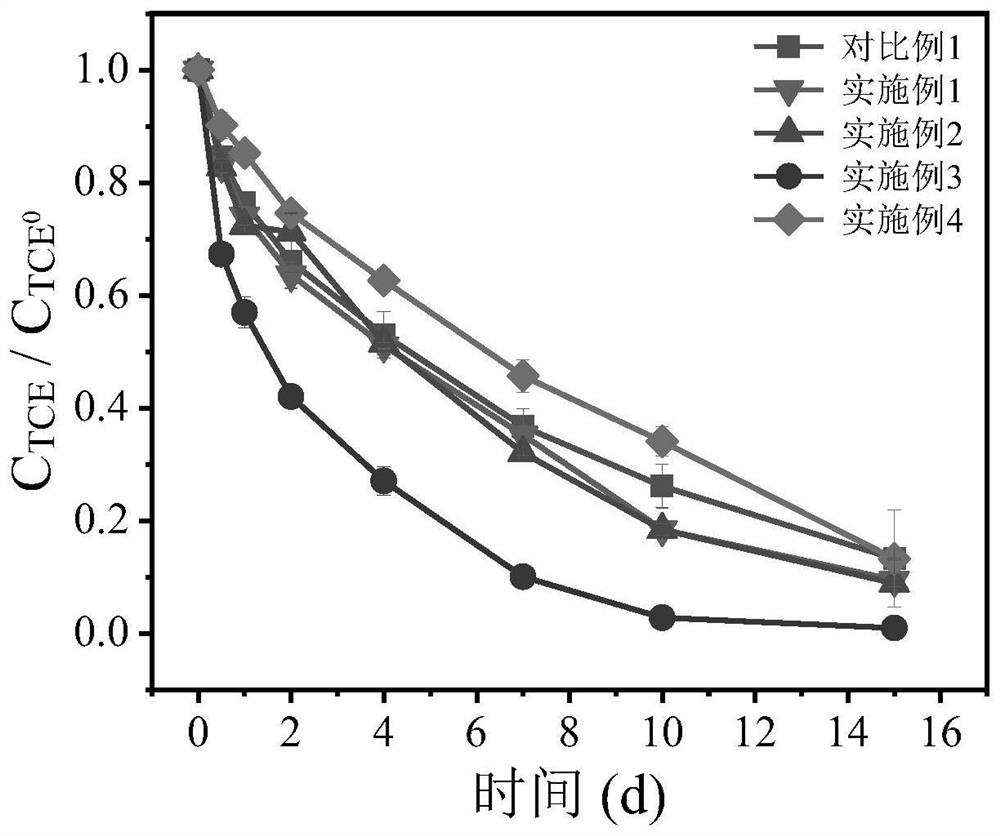

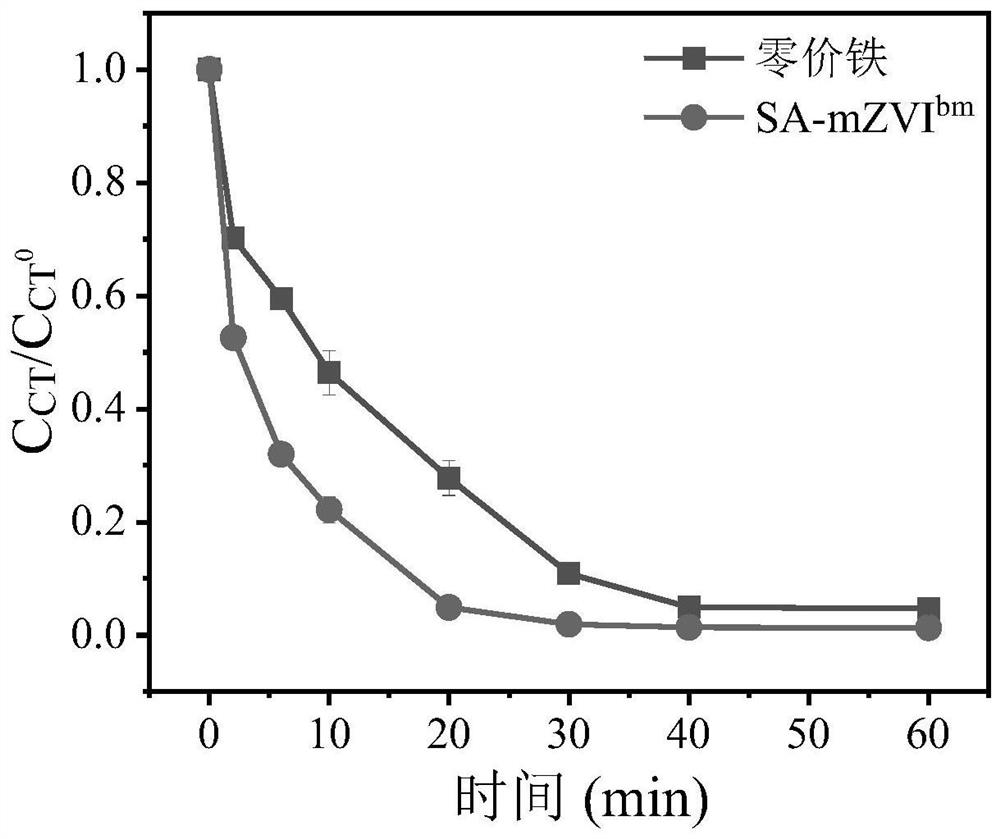

[0035] Preparation of SA-mZVI by planetary ball mill bm , the steps are as follows: (1) zirconia ball milling beads (6mm in particle size) with 20% cavity volume are packed into the ball mill jar as the grinding medium; (2) weigh 0.00125g stearic acid and 2.49875g zero-valent iron powder (hard The mass ratio of fatty acid and iron (1:2000) is placed in the ball mill jar, and is full of argon in the jar; (3) open ball mill, ball mill speed is transferred to 400rpm, ball mill 20 hours; (4) under nitrogen atmosphere, Sieve the prepared SA-mZVI bm Separation from grinding media to obtain SA-mZVI bm finished product.

Embodiment 2

[0037] Preparation of SA-mZVI by planetary ball mill bm , the steps are as follows: (1) the zirconia ball milling beads (6mm in particle diameter) of 20% cavity volume are packed in the ball mill jar as grinding medium; (2) take by weighing 0.0025g stearic acid and 2.4975g zero-valent iron powder ( The mass ratio of stearic acid and iron (1:1000) is placed in the ball mill jar, and is filled with argon in the jar; (3) Open the ball mill, adjust the ball mill speed to 400rpm, and ball mill for 20 hours; (4) Under nitrogen atmosphere , the prepared SA-mZVI was sieved bm Separation from grinding media to obtain SA-mZVI bm finished product.

Embodiment 3

[0039] Preparation of SA-mZVI by planetary ball mill bm , the steps are as follows: (1) the zirconia ball milling beads (6mm in particle diameter) of 20% cavity volume are packed in the ball mill jar as grinding medium; (2) take by weighing 0.0125g stearic acid and 2.4875g zero-valent iron powder ( The mass ratio of stearic acid and iron (1:200) is placed in the ball mill jar, and is filled with argon in the jar; (3) Open the ball mill, adjust the ball mill speed to 400rpm, and ball mill for 20 hours; (4) Under nitrogen atmosphere , the prepared SA-mZVI was sieved bm Separation from grinding media to obtain SA-mZVI bm finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com