Sodium silicate modified zero-valent iron composite material as well as preparation method and application thereof

A composite material and sodium silicate technology, applied in the field of environmental chemistry, can solve the problems of hindering the contact of active ingredients, reducing the activity of zero-valent iron, poor selectivity, etc., and achieve the effects of inhibiting cold welding, increasing fracturing rate, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

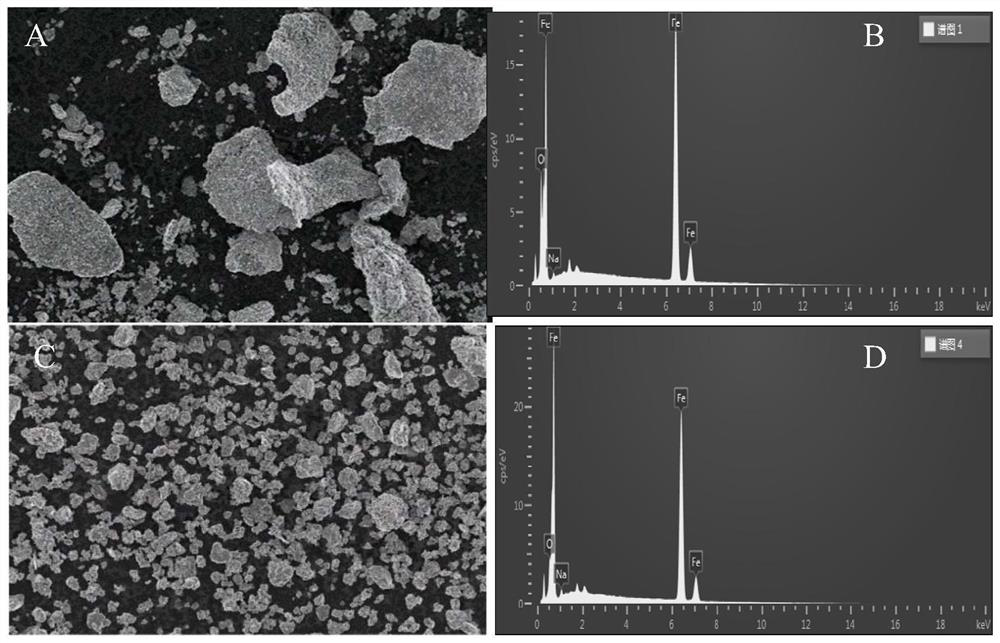

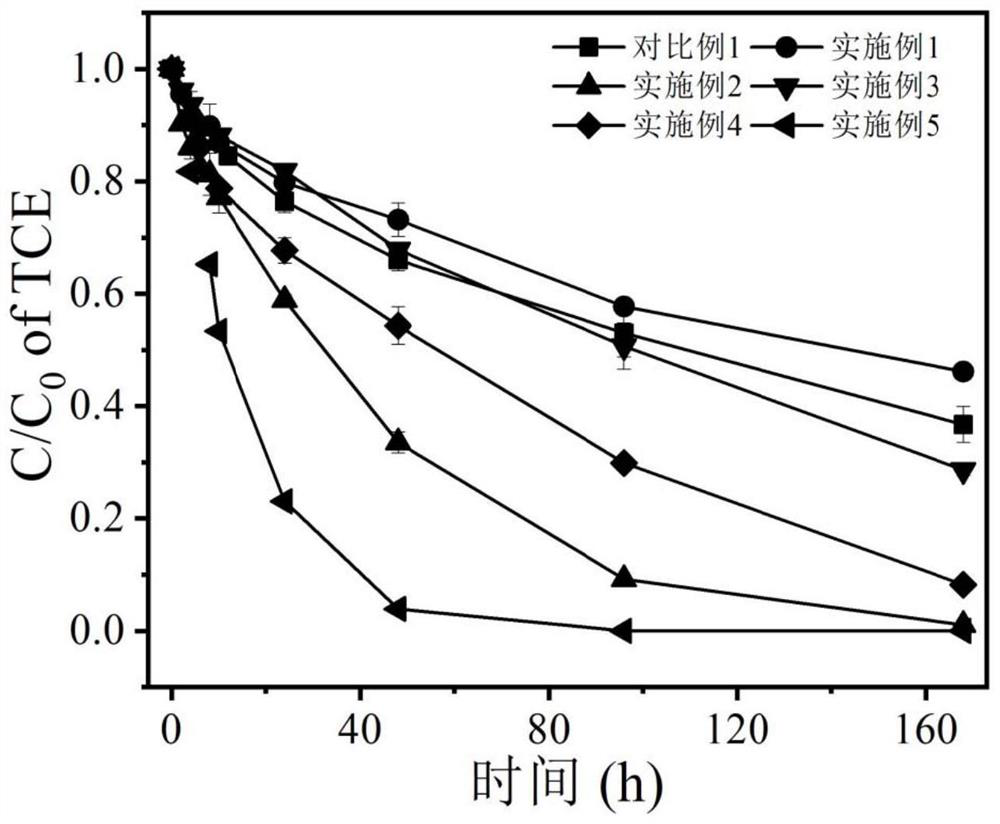

[0036] Preparation of NSzero-mZVI by Planetary Ball Mill bm , the steps are as follows: (1) put 20% of the cavity volume of zirconia balls (particle size 6mm) into the ball mill as grinding media; (2) weigh 0.00011g of anhydrous sodium silicate and 2.49989g of zero-valent iron powder (The mass ratio of anhydrous sodium silicate and iron is 1:20000) placed in the ball mill tank, and filled with argon gas; (3) turn on the ball mill, adjust the ball milling speed to 400rpm, and mill the ball for 20 hours; (4) in the Under nitrogen atmosphere, the prepared NSzero-mZVI was screened with a mesh bm Separated from grinding media to obtain NSzero-mZVI bm finished product.

Embodiment 2

[0038] Preparation of NSzero-mZVI by Planetary Ball Mill bm , the steps are as follows: (1) put 20% of the cavity volume of zirconia balls (particle size 6mm) into the ball mill as grinding media; (2) weigh 0.00044g anhydrous sodium silicate and 2.49956g zero-valent iron powder (The mass ratio of anhydrous sodium silicate and iron is 1:5000) placed in the ball mill tank, and filled with argon gas in the tank; (3) turn on the ball mill, adjust the ball milling speed to 400rpm, and mill the ball for 20 hours; (4) in the Under nitrogen atmosphere, the prepared NSzero-mZVI was screened with a mesh bm Separated from grinding media to obtain NS H2O -mZVI bm finished product.

Embodiment 3

[0040] Preparation of NSzero-mZVI by Planetary Ball Mill bm , the steps are as follows: (1) put 20% of the cavity volume of zirconia balls (particle size 6mm) into the ball mill as grinding media; (2) weigh 0.00055g anhydrous sodium silicate and 2.49978g zero-valent iron powder (The mass ratio of anhydrous sodium silicate and iron is 1:4000) placed in the ball mill tank, and filled with argon gas in the tank; (3) turn on the ball mill, adjust the ball milling speed to 400rpm, and mill the ball for 20 hours; (4) in the Under nitrogen atmosphere, the prepared NSzero-mZVI was screened with a mesh bm Separated from grinding media to obtain NS H2O -mZVI bm finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com