Two-phase ammonifying method of wet ammonia desulfurization process

An ammonia-based desulfurization and process technology, applied in the field of resources and environment, can solve problems affecting the safety of absorption towers or storage tanks, increase transportation costs, increase water consumption, etc., facilitate the ammonia water configuration process, improve ammonia utilization efficiency, and ensure the The convenient effect of ammonia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

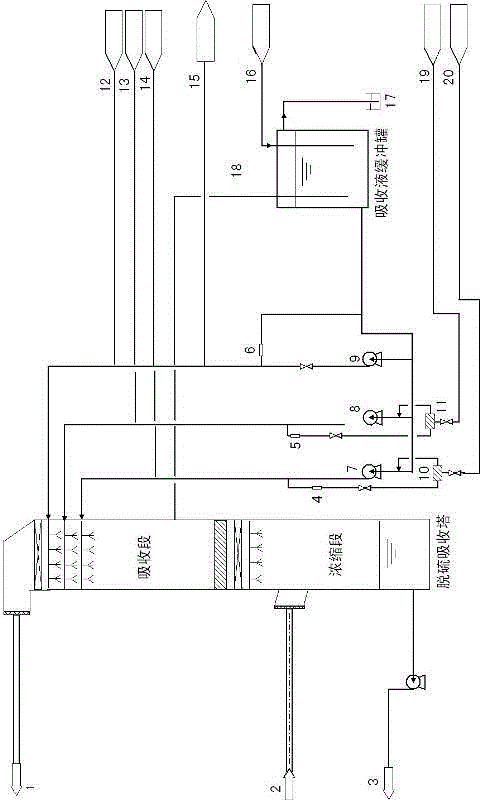

[0022] The specific embodiment of the present invention is:

[0023] a. Set up an absorbent buffer tank;

[0024] b. Fully mix the liquid ammonia from the liquid ammonia tank with the solution from the absorbent buffer tank at the static mixer at the outlet of the buffer tank;

[0025] c. Adjust the amount of liquid ammonia added according to the pH value of the solution at the outlet of the static mixer, and then enter the desulfurization absorption tower as an absorbent to absorb SO in the flue gas 2 Recycle into the absorption buffer tank;

[0026] d. The gas-phase ammonia from the liquid ammonia tank is directly added to the absorbent buffer tank to dissolve in the absorption liquid;

[0027]e. Part of the absorption liquid in the absorption liquid buffer tank is pumped to the oxidation tank for oxidation crystallization to maintain the material balance of the system.

[0028] see figure 1 , figure 1 It is a process flow diagram of a two-phase ammonia addition method ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com