High-flash-point odorless coating as well as preparation method and application thereof

A high-flash point, clean-odor technology, applied in the field of coatings, can solve problems such as low flash point, flammability, and threats to human health, and achieve high flash point, safe and convenient transportation and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

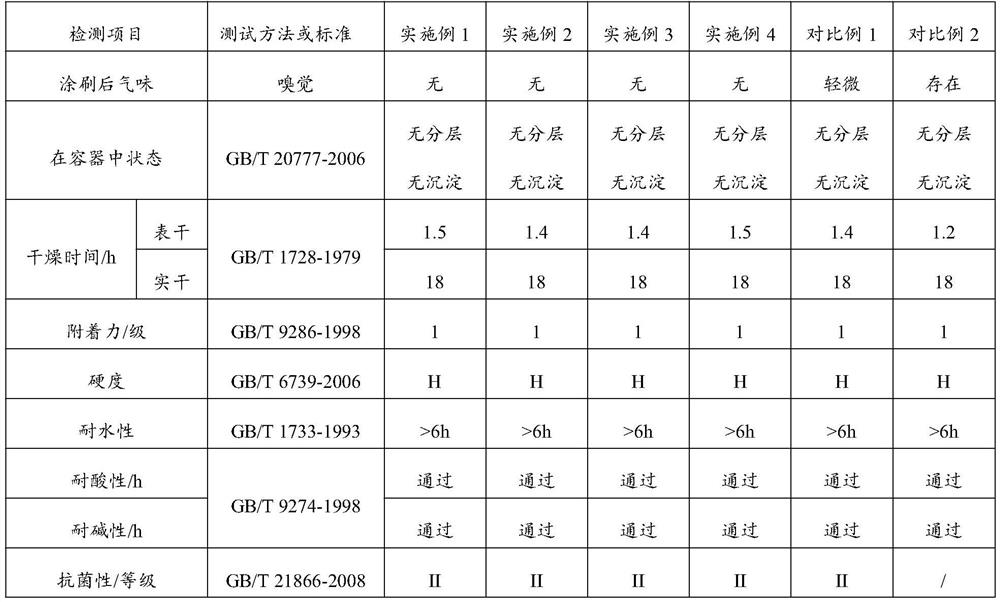

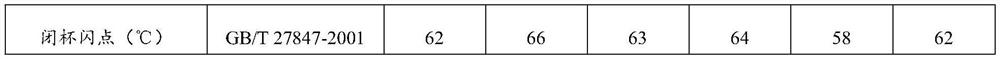

Examples

preparation example Construction

[0043] The present invention also provides the preparation method of the high-flash-point deodorant coating described in the above technical solution, comprising the following steps:

[0044] adding dispersant, anti-settling agent, wetting agent, film-forming aid and drier to the solvent, and dispersing to obtain the first solution;

[0045] Mixing the alkyd resin and terpineol with the first solution, and dispersing to obtain an emulsion;

[0046] The anti-skinning agent, zinc oxide and titanium dioxide are mixed with the emulsion and dispersed to obtain a high-flash-point clean-odor paint.

[0047] In the present invention, the dispersing agent, anti-settling agent, wetting agent, film-forming aid and drier are dispersed in a solvent to obtain a first solution. In the present invention, it is preferable to add dispersant, anti-settling agent, wetting agent, film-forming aid and drier to the solvent, and disperse the obtained mixed solution to obtain the first solution. In ...

Embodiment 1

[0055] Add 0.5 part of drier Borchers Dry0411HS, 0.3 part of dispersant Triton XN-45S, 0.5 part of anti-settling agent BYK-410, 0.2 part of wetting agent triton X-405, 5 part of film-forming aid dipropylene glycol butyl ether and added 14 parts of In D40 solvent, after dispersing at 500r / min for 10min, the first solution was obtained;

[0056] 50 parts of 389-9 alkyd resin and 5 parts of ɑ-terpineol were added to the first solution, and after being dispersed at 1000r / min for 20min, an emulsion was obtained;

[0057] Add 0.2 part of anti-skinning agent butanone oxime, 7 parts of zinc oxide and 18 parts of titanium dioxide into the emulsion, and after dispersion at 1500r / min for 20min, the finished paint with high flash point and clean taste is obtained.

Embodiment 2

[0059] Mix 0.6 parts of drier Borchers Dry0411HS, 6 parts of D40 solvent oil and 7.5 parts of D60 solvent to obtain a mixed solvent;

[0060] Add 0.3 part of dispersant Triton XN-45S, 0.5 part of anti-settling agent BYK-410, 0.2 part of wetting agent triton X-405, 5.5 part of film-forming aid dipropylene glycol butyl ether into the mixed solvent, disperse at low speed at 600r / min After 10min, the first solution was obtained;

[0061] 0.2 part of anti-skinning agent butanone oxime, 52 parts of 389-9 alkyd resin, 6 parts of ɑ-terpineol were added to the first solution, and after high-speed dispersion at 1000r / min for 20min, an emulsion was obtained;

[0062] Add 8 parts of zinc oxide and 14 parts of titanium dioxide into the emulsion, and after high-speed dispersion at 1500r / min for 20min, the finished paint with high flash point and clean taste is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com