Method of constructing a wall or roof using a contained load transfer device for wood sheathing products

a technology of load transfer device and wood sheathing, which is applied in the direction of roofs, walls, constructions, etc., can solve the problems of difficult application of adhesive tape, certain reduction of potential adhesion, and high undesirable effects of such a purpose, and achieves convenient and safe installation, reliable attachment of such devices, and convenient and safe manner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

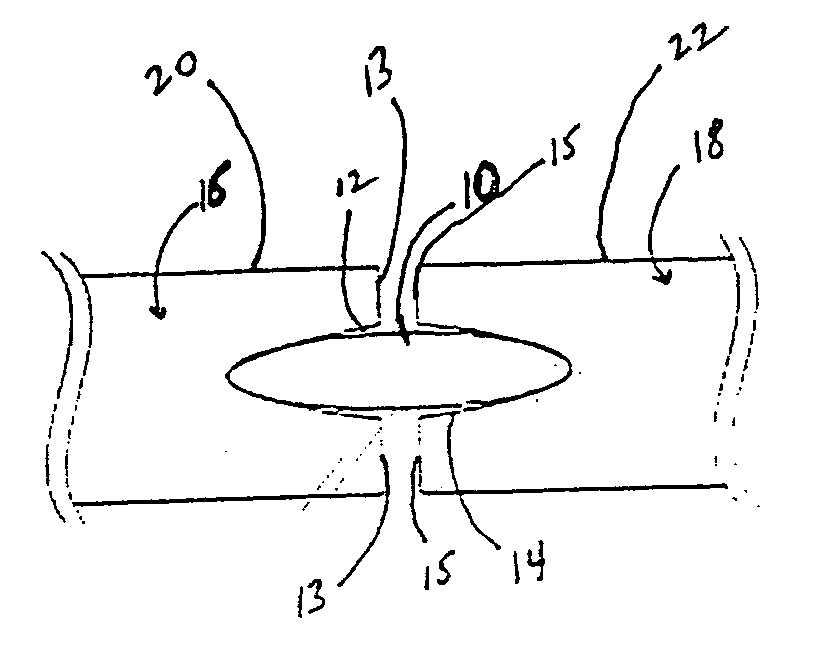

[0022]FIG. 1 shows a cross-sectional perspective of a disk 10 inserted within the cavities 12, 14 of peripheral edges 13, 15 of two adjacent wood boards 16, 18. As can be seen, the disk 10 is flush with the internal portions of said cavities 12, 14 to the degree that a distance between both boards 16, 18 is evident. A tape (not illustrated) may then be applied in contact with the top portions 20, 22 of both wood boards 16, 18. When multiple disks are utilized, the distance between the wood boards 16, 18, will be roughly uniform along the peripheral edges 13, 15.

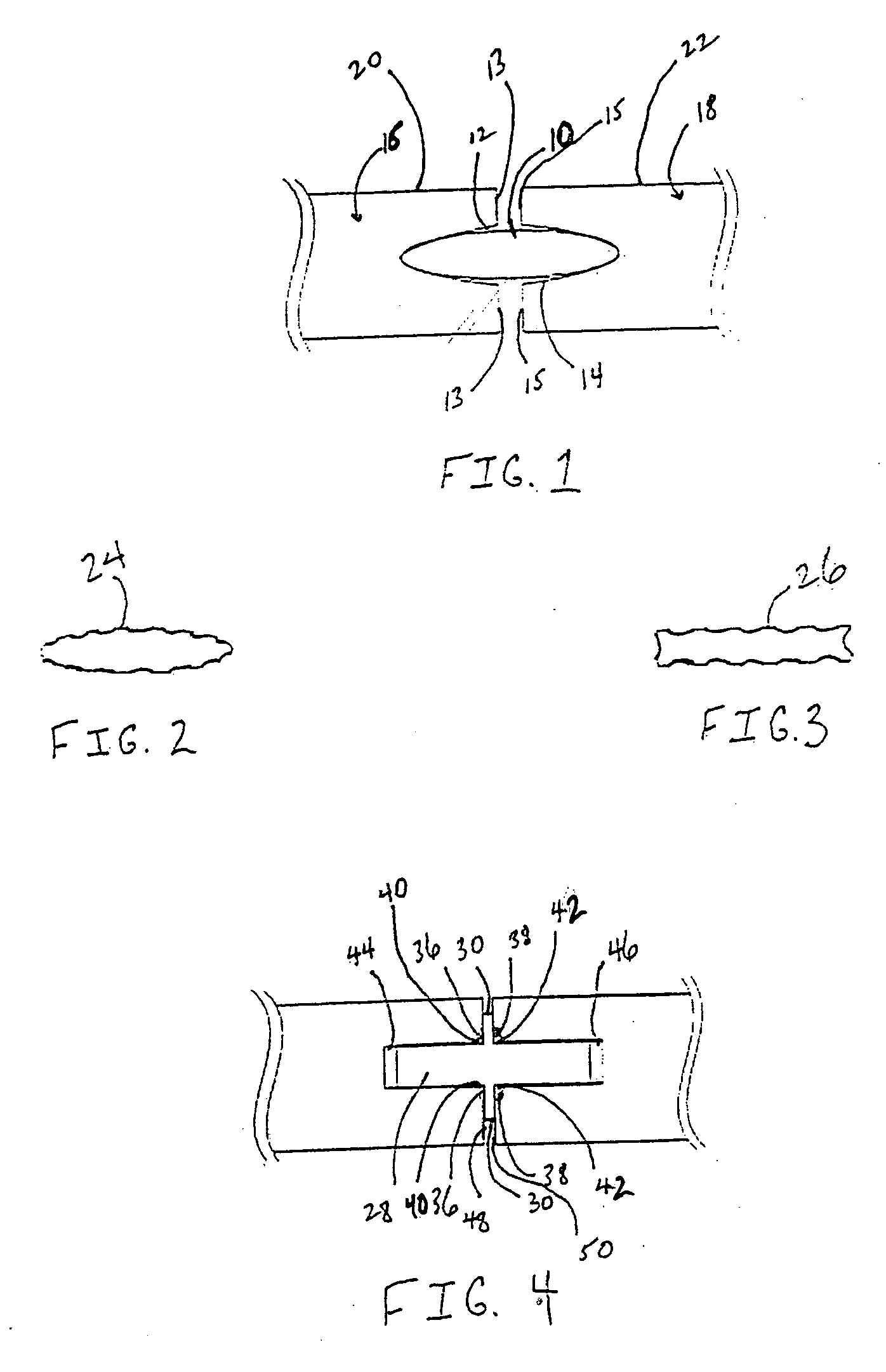

[0023] The disks of FIGS. 2 and 3 merely show that such devices, either oval in shape 24, or rectangular in shape 26, may be modified or produced originally in such a manner as to impart an increase in surface area thereto to aid in adhering such devices to the cavities in which they are inserted within wood boards (not illustrated).

[0024]FIG. 4 depicts a cross-sectional perspective of a different potential embodiment where...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com