Novel wooden box for packaging external rotor axial flow fan

A technology of axial fans and packing wooden boxes, applied in packaging, transportation and packaging, rigid containers, etc., can solve the problems of loose installation, damage, economic loss of enterprises or customers, etc., to achieve tight and reliable installation, and prevent damage to fan equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

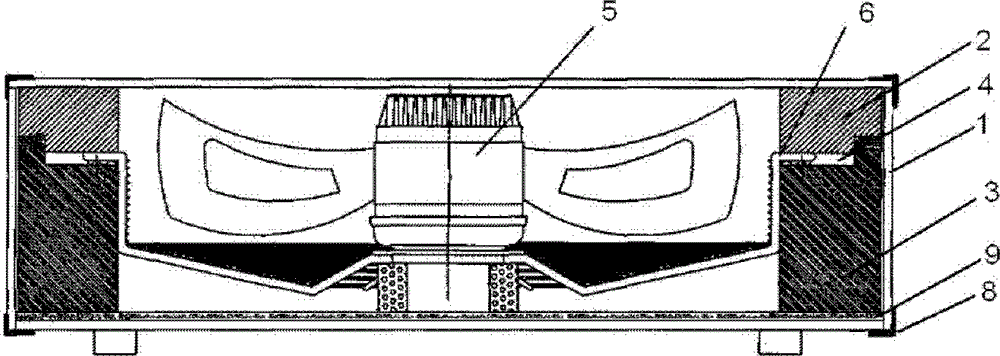

[0012] Such as figure 1 As shown, a wooden box for packing a new type of external rotor axial flow fan, it includes a box body 1, a foam bottom plate 9 is provided at the bottom of the box body 1, and an upper foam block 2 and a lower foam block are provided at the four corners of the box body 1 3. The main body section of the upper foam block 2 and the lower foam block 3 is a right triangle, and the two sides of the right angle are pressed against the inner wall of the box body 1, and the mating surface between the upper foam block 2 and the lower foam block 3 is a dislocated step Shaped structure, a part of the mating surface leaves a gap 4 for placing the mounting rib 6 of the outer rotor axial fan 5 . The four corners of the casing are connected by tinplate 8.

[0013] When installing: first install the foam bottom plate 9 in the box bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com