Loading and swing conveying device for automobile seat shaft clamping bolts

A technology of clamping and installing the seat shaft, which is applied in the direction of positioning device, clamping, support, etc., and can solve the problem of inconvenient and fast installation or disassembly of the mounting seat, inclination angle of non-adjustable device placement, and inaccurate flipping and clamping bolts, etc. problems, to achieve good social and economic benefits, easy and quick installation or disassembly, compact and reliable installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

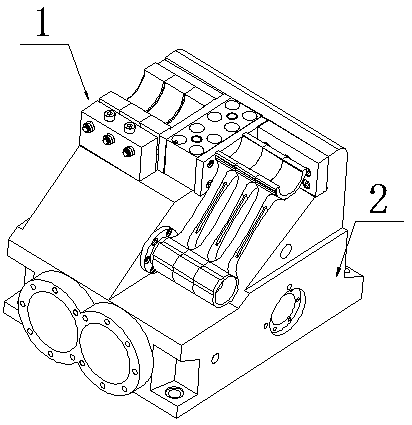

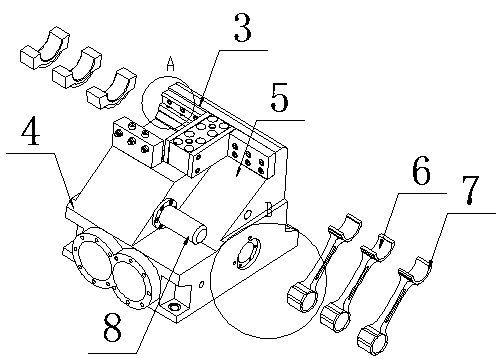

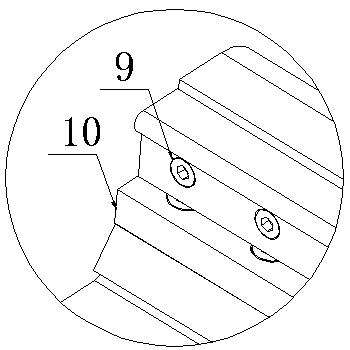

[0021] Such as Figure 1 to Figure 6 As shown, the installation and placement device 1 for the automobile seat shaft clamping bolt includes a base 2, a mounting seat 3 is arranged above the base 2, and a motor disk 4 is fixedly connected to the bottom of the mounting seat 3. The motor disk One side of the 4 is obliquely provided with a card slot 5, the outer wall of the motor disk 4 runs through a transmission shaft 8, and three swing frames 6 are sleeved on the transmission shaft 8, and a magnetic suction groove 7 is arranged above the swing frame 6, the A plurality of rotary bolts 9 are installed inside the loading seat 3, a baffle plate 10 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com