Tree bast fiber and processing method therefor

A technology of bast fiber and processing method, which is applied in the field of textile fibers, can solve the problems that it is impossible to provide mulberry bark, and achieve the effects of excellent dyeing performance, wide application prospects, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

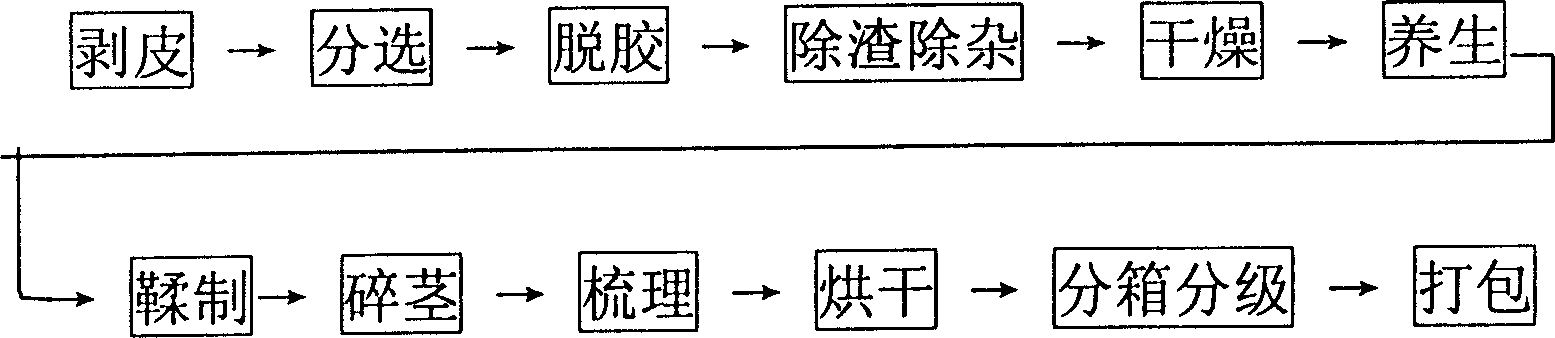

Method used

Image

Examples

Embodiment 1

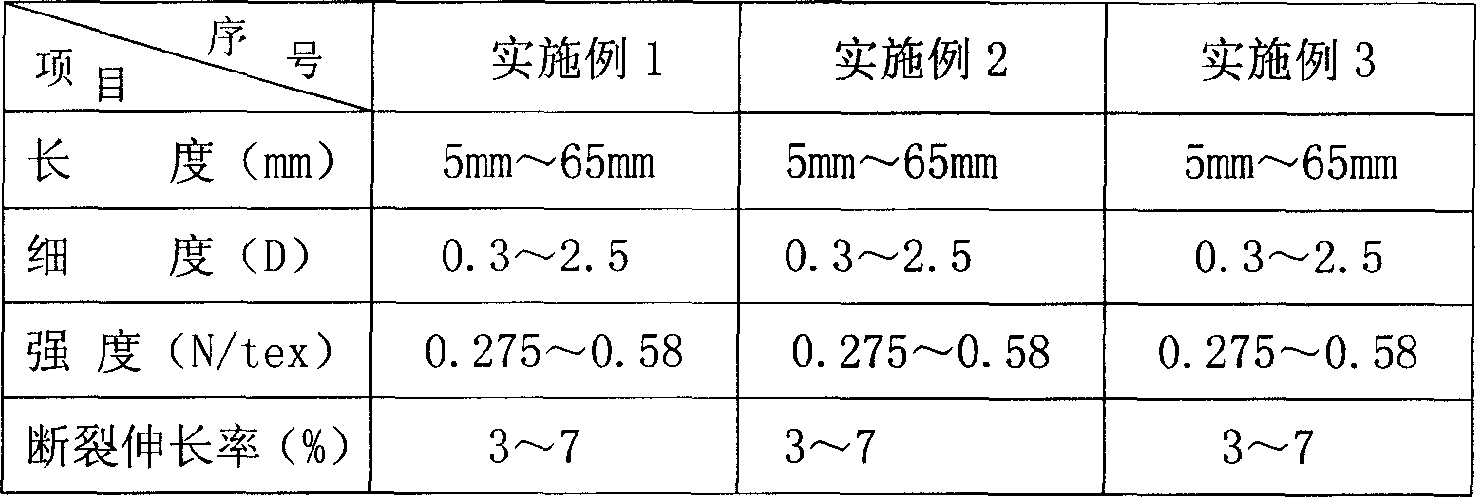

[0025] Take the elm tree that has just been felled, remove the old bark on the surface of the tree by hand, and then separate the bast layer from the tree stem. Try to avoid bringing in the hard wood fiber layer in the tree stem, and classify it according to the size of the bast bark of the tree. The tree bast with substantially the same size is put into a pool of 12g / L sodium hydroxide concentration, 0.5% by weight washing powder, and a temperature of 60°C. After soaking for 12 hours, take it out and dry it. After evenly spraying the emulsion in the humidification chamber, cover it with a cloth for 18 hours of health preservation; put the health care treatment into a mixture containing 1.5% of Remy Bang A, 0.5% of JFC, 1% of palm oil, 1% of motor oil and water 1:20 The tanning agent is used for tanning, and the tanned bast fiber is cut into about 70mm, opened and fiberized by a cotton opener, put into a carding machine for 3 to 5 times of carding, and the carded fiber is colle...

Embodiment 2

[0027] Get freshly felled willow branches, separate the bark from the stems by hand, put the sodium hydroxide concentration at 3g / L, add washing powder with 1% by weight, and soak in a pool at 20°C for 48 hours Finally, take it out and dry it, put it into the humidification chamber, spray the emulsion evenly, and cover it with a cloth for 24 hours of health preservation; put the bast fiber after the health care treatment into the water containing the following weight percentages: 2% penetrant M, 1% JFC , 1% peanut oil, 1% engine oil in normal temperature water for tanning, the bast fibers after tanning are cut into about 70mm, opened and fibered with a cotton opener, placed in a carding machine for 3 to 5 times, collected and carded The finished fibers were dried in an oven and then separated into bast fibers of different specifications by an airflow classification box. The properties of the fibers are shown in Table 1.

Embodiment 3

[0029] Get the oleander just felled, bark is separated from bark by hand, and bark is put into sodium hydroxide concentration and is 8g / L, adds the washing powder of 1% weight part, and temperature is in the pool of 50 ℃, After soaking for 24 hours, take it out and dry it, put it into the humidification chamber, spray the emulsion evenly, and then cover it with cloth for 24 hours; put the bast fiber after the health treatment into the water containing the following weight percentage: 1% Remybang A. Soak and tan with 1% Pingpingjia, 1% JFC, 1% vegetable oil, and 1% machine oil in water at 40°C, cut the bast fiber after tanning into about 70mm, open it with a cotton opener, and put it into carding Carding is carried out in the machine for 3 to 5 times, and the combed fibers are collected and dried in an oven, and then separated into bast fibers of different specifications through an airflow classification box. The fiber properties are shown in Table 1.

[0030] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com