Coconut fiber automobile backrest and method for manufacturing back cushion of backrest

A technology of coconut palm fiber and a manufacturing method, which is applied to back cushions, plant fibers of other plant materials, non-woven fabrics, etc., can solve the problems of high manufacturing cost, unenvironmental protection, poor air permeability, etc., and achieves low manufacturing cost and air permeability. The effect of good performance and rich source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

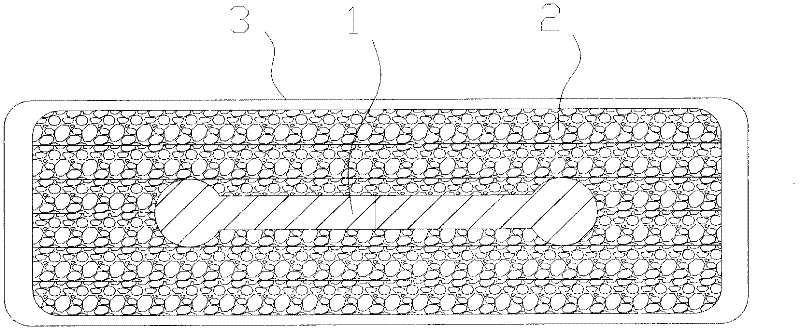

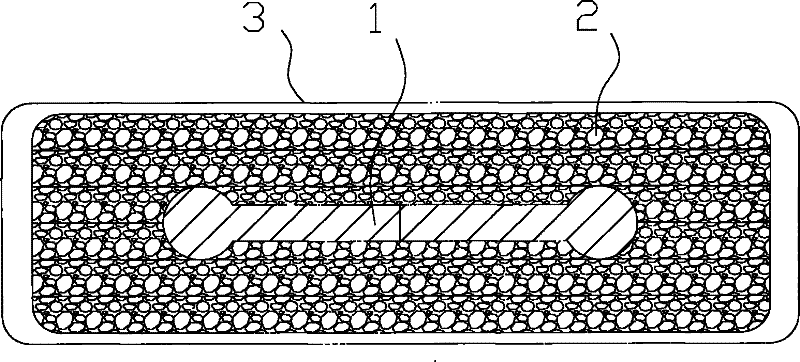

[0017] figure 1 Schematically shows the cross-sectional structure of the preferred embodiment of the present invention, as shown in it, the coconut palm fiber automobile backrest that the preferred embodiment of the present invention provides comprises the coconut palm fiber layer 2 of backrest support structure 1, wrapping fabric 3 and multilayer stacking , that is, the car back cushion layer of the present preferred embodiment is the coconut palm fiber layer 2, and the coconut palm fiber layer 2 superimposed successively is arranged on the back support structure 1, and the wrapping fabric layer 3 is coated on the coconut palm fiber layer 2 stacked in multiple layers superior. Of course, in other embodiments, a thicker coconut palm fiber layer can also be set, but its strength is not as good as this preferred embodiment.

[0018] E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com