Manufacturing method of seaweed carbon fiber blended fabric

A technology of seaweed carbon fiber and blended fabric, which is applied in the processing of textile materials, continuous processing of textile materials, plant fibers of other plant raw materials, etc., can solve the problem of low strength of alginate fibers, unsuitable for socks production, and decreased elongation at break. and other problems, to achieve good far-infrared radiation performance, improve comprehensive performance and market competitiveness, strong strength and elongation at break.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

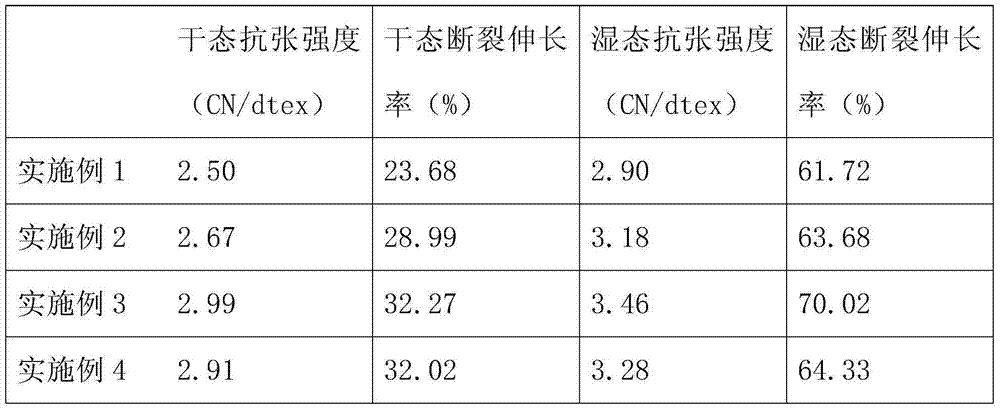

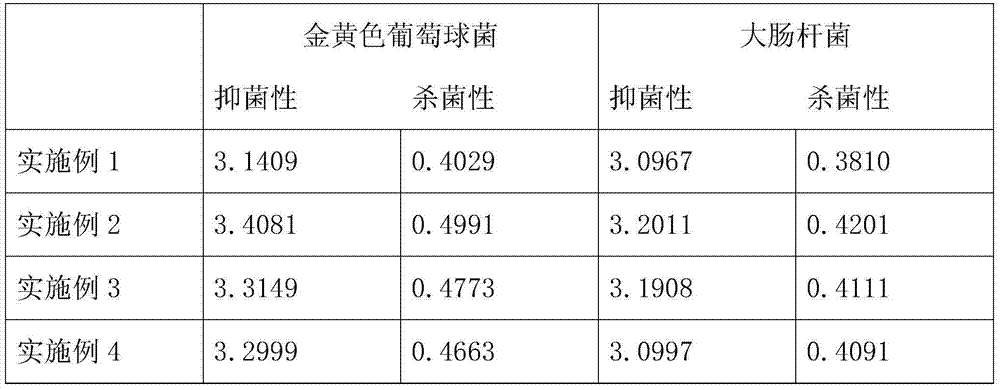

Examples

Embodiment 1

[0029] Embodiment 1 of the present invention provides a kind of preparation method of seaweed carbon fiber blended fabric, and it is made through the following steps:

[0030] A) seaweed pretreatment: remove the rhizoids and rotten leaves of kelp, clean and cut into 3-4cm fragments, dry the kelp fragments in an oven at 90°C until the water content is 9%; then dry the seaweed The kelp section is crushed in a grinder to 0.3-0.5cm;

[0031] B) Burning seaweed carbon: the seaweed powder obtained in step A) is sent into the carbonization furnace for the following three steps:

[0032] (B1) Drying treatment: first raise the temperature in the carbonization furnace to 100°C at a rate of 1-3°C / min, then raise the temperature to 180°C at a rate of 5-7°C / min and hold at this temperature Keep warm for 2.5 hours;

[0033] (B2) Pre-carbonization treatment: raise the temperature from 180°C to 230°C at a rate of 8-10°C / min, and keep it at 230°C for 5 hours;

[0034] (B3) Carbonization and...

Embodiment 2

[0049] The difference between Example 2 of the present invention and the above-mentioned Example 1 is that the seaweed treated in step A) is Sargassum. All the other steps are the same as in Example 1.

Embodiment 3

[0051]The difference between Example 3 of the present invention and the above-mentioned Example 1 is that: in step C), seaweed carbon fiber and modal fiber are blended, and the two are mixed and cleaned into rolls. All the other steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com