Patents

Literature

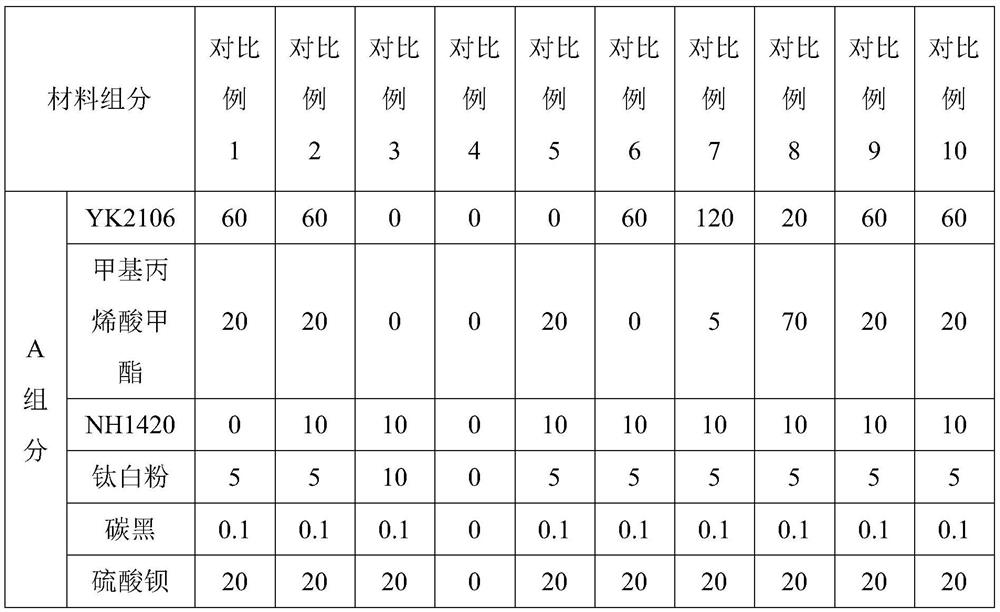

46results about How to "Strong elongation at break" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite sole hot melt adhesive film and preparation method thereof

InactiveCN112226180AHigh bonding strengthHigh mechanical strengthPolyureas/polyurethane adhesivesMacromolecular adhesive additivesElastomerPolymer science

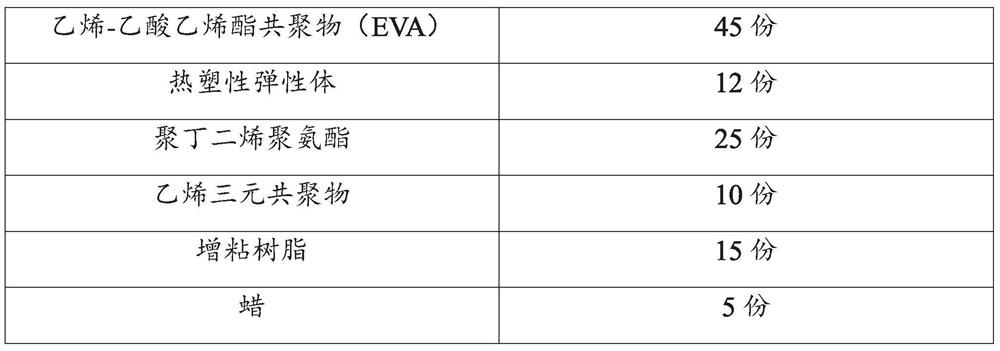

The invention belongs to the technical field of high polymer materials, and particularly discloses a composite sole hot melt adhesive film and a preparation method thereof. The composite sole hot meltadhesive film is prepared from the following raw materials in parts by weight: 40-50 parts of ethylene-vinyl acetate copolymer, 5-15 parts of thermoplastic elastomer, 20-30 parts of polybutadiene polyurethane, 2-10 parts of ethylene terpolymer, 5-15 parts of tackifying resin, 3-10 parts of reinforcing filler, 3-8 parts of wax and 0.1-1 part of antioxidant. The composite sole hot melt adhesive film is used for bonding an outsole and a mid-low sole of a shoe material, only needs to be attached to the outsole and the mid-low sole for hot pressing when used, and has the advantages of being easy to operate, firm in bonding, durable, non-toxic, environmentally friendly, high in yield and the like. The preparation process of the composite sole hot melt adhesive film is simple, convenient to operate and convenient for mass production.

Owner:厦门联合信诺新材料有限公司

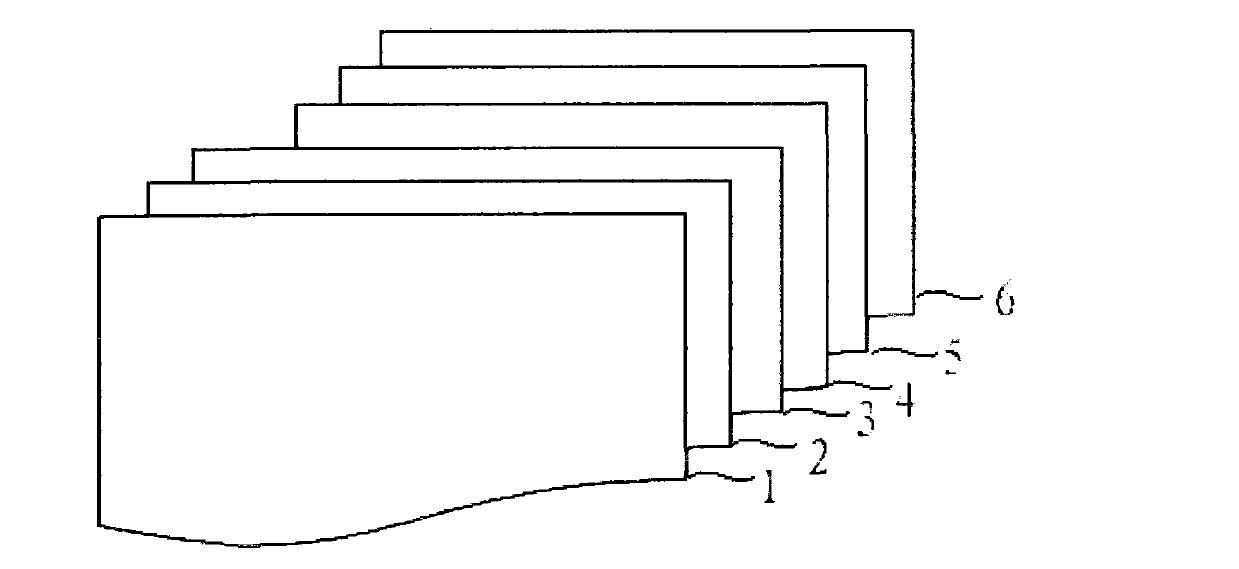

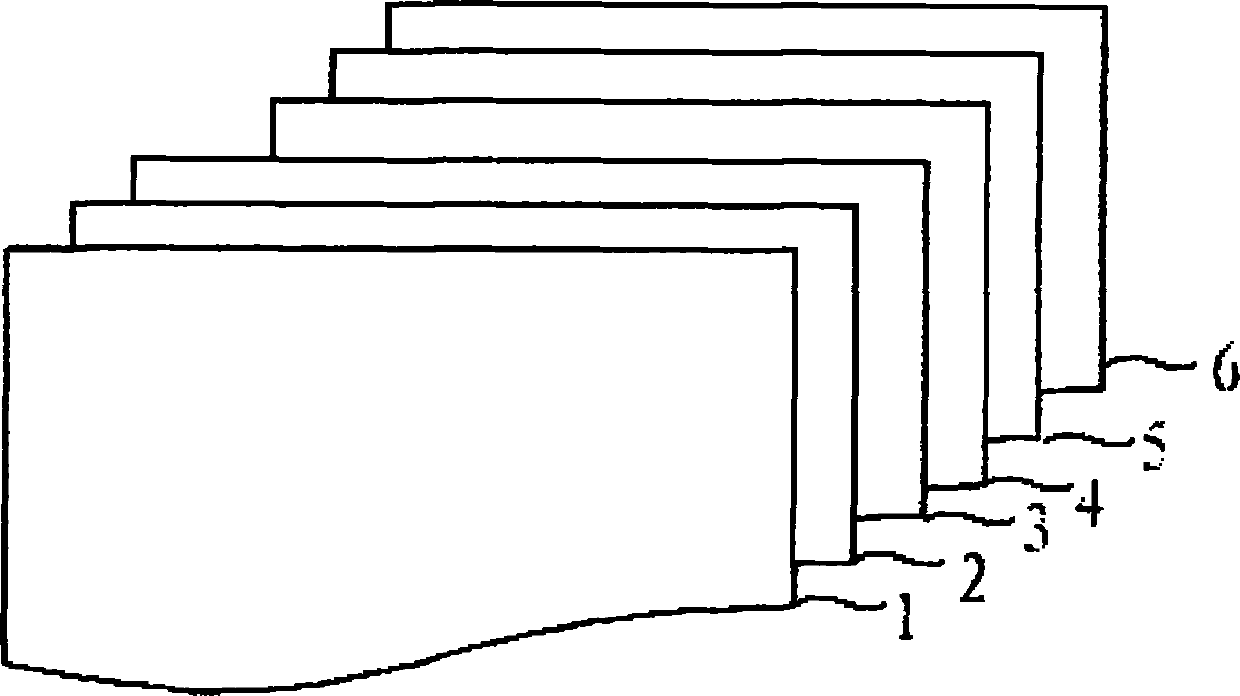

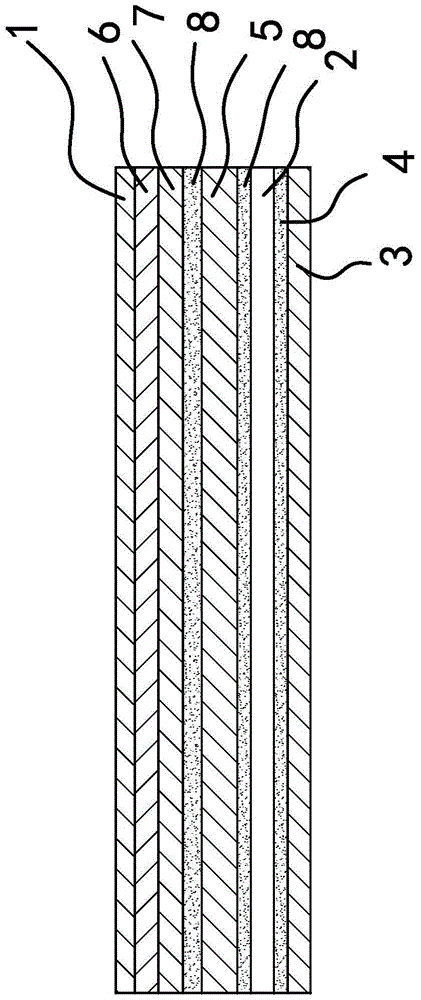

Layered broadband radar absorbing plate and manufacturing method thereof

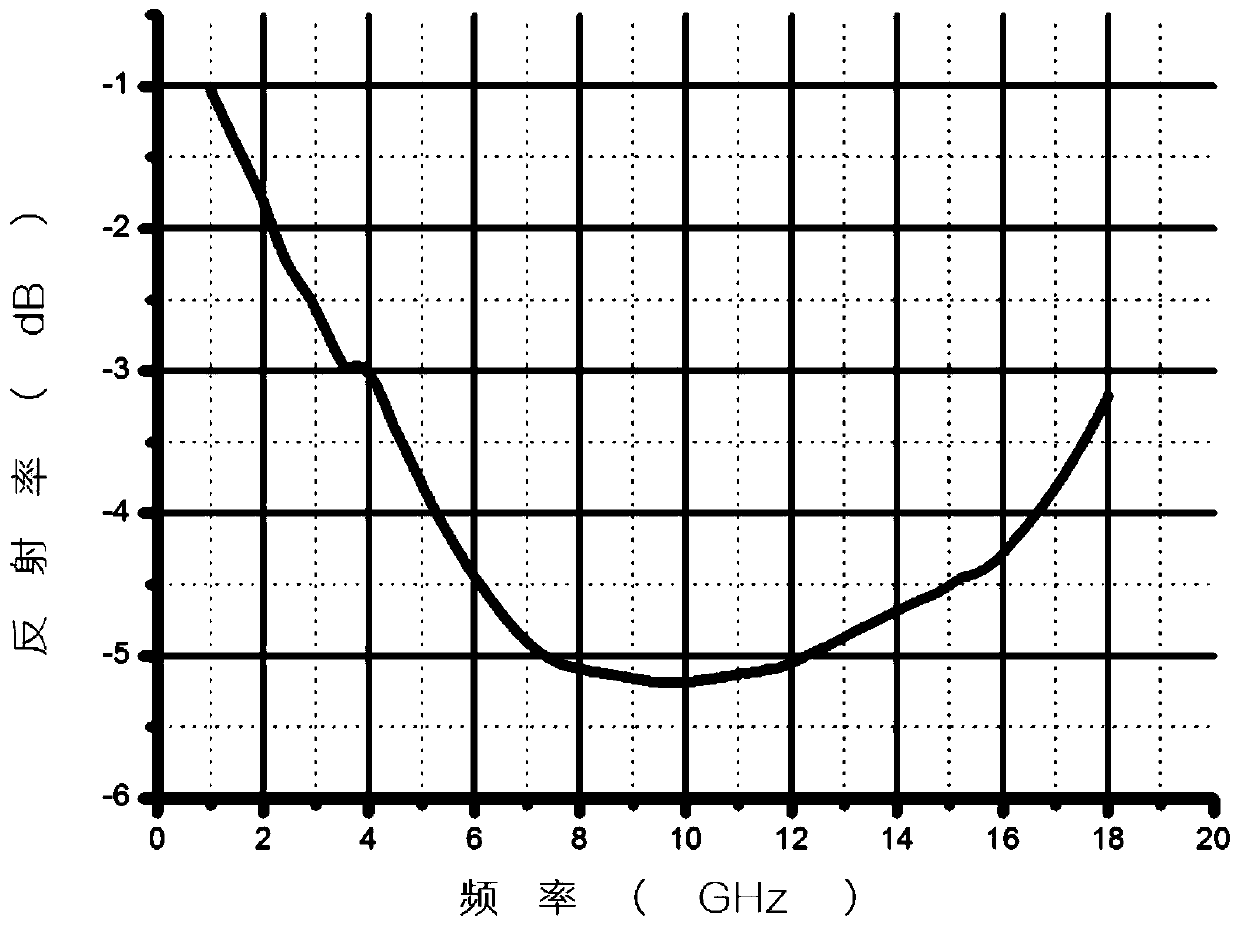

ActiveCN108092006AAbsorption BandwidthImprove microwave absorptionLamination ancillary operationsSynthetic resin layered productsVulcanizationAbsorption rate

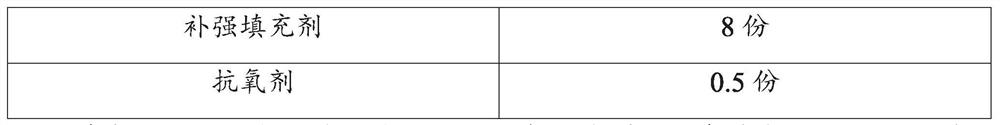

The invention discloses a layered broadband radar absorbing plate. The absorbing plate is a multilayer absorbing film. The multilayer absorbing film has five layers which are a first layer of a spherical carbonyl iron film, second and third layers of flaky carbonyl iron films, fourth and fifth layers of sheet Fe-Si-Al films from top to bottom in sequence. The invention also discloses a manufacturing method of the above-mentioned absorbing plate. The layered broadband radar absorbing plate of the present invention utilizes the principle of electromagnetic matching, the stress orientation technology, and the production technology of coating, rolling and vulcanization comprehensively. The finished product is characterized by high microwave absorption rate, a wide absorption frequency band, athin thickness, small surface density, high elongation at break, strong adhesion, high and low temperature resistance, flame retardance, easy usage, etc., and has wide application prospects in microwave stealth transformation of radar, communications equipment, satellite navigation, electrical equipment, notebooks, base stations, medical equipment and other electronic industries and weapons and equipment, and especially the stealth transformation of aerospace vehicles.

Owner:南京冠旭新材料科技有限公司

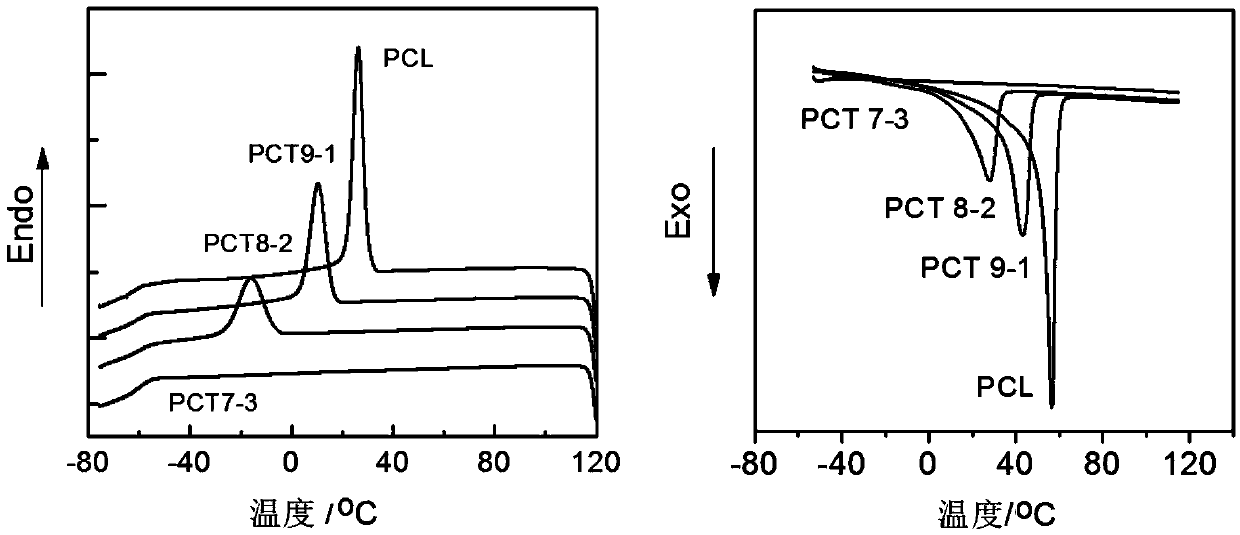

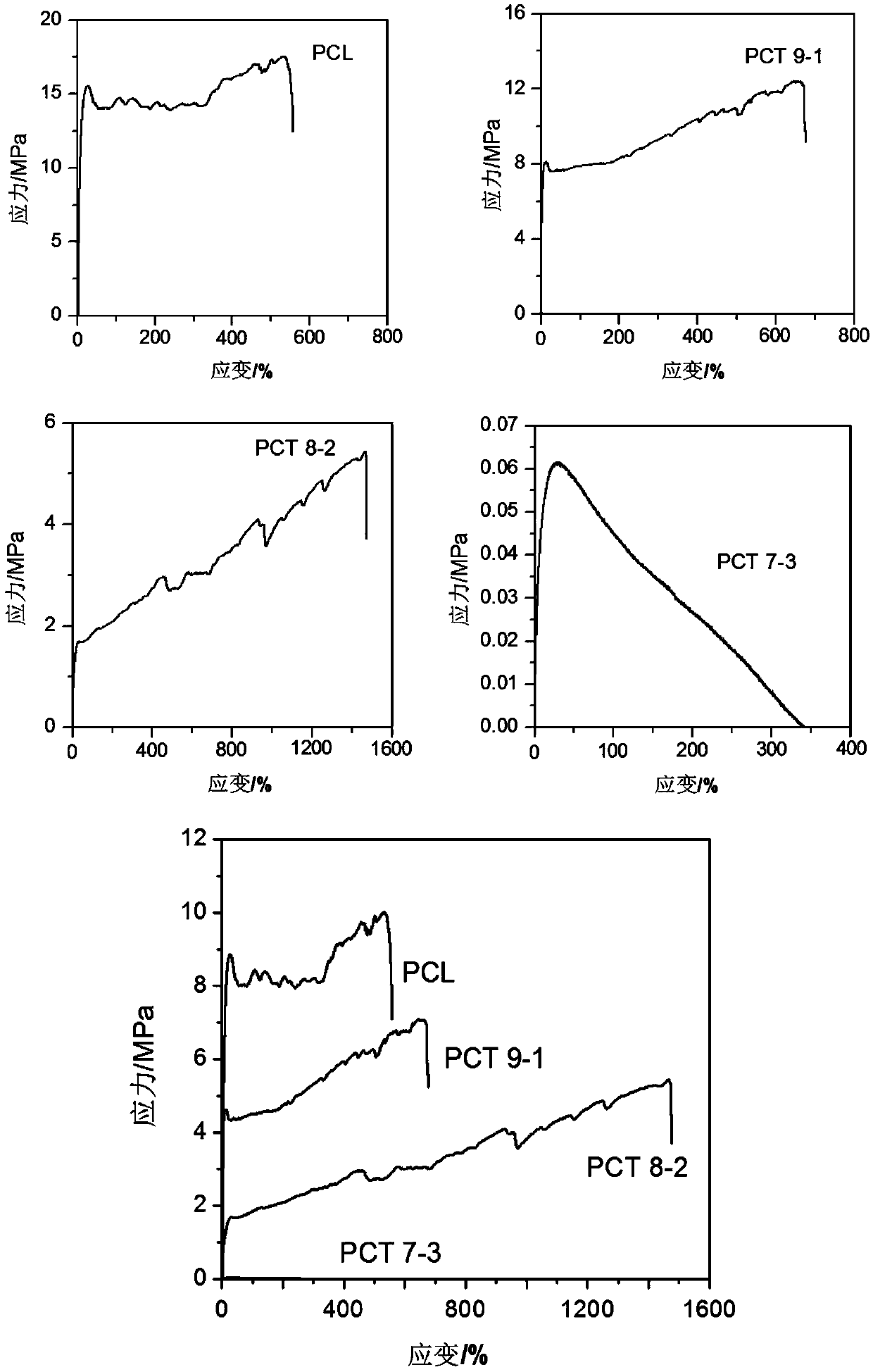

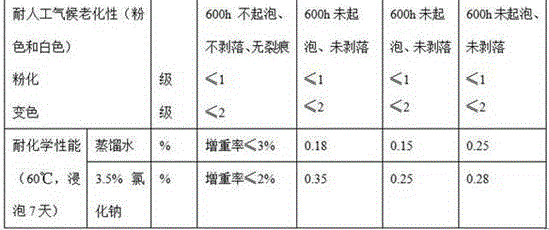

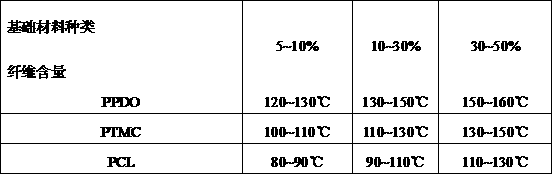

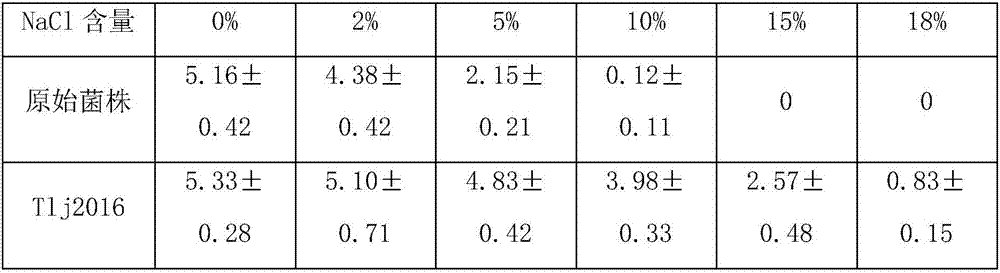

Preparation and application of linear biodegradable polyester elastomer with controllable elasticity and shape memory effect

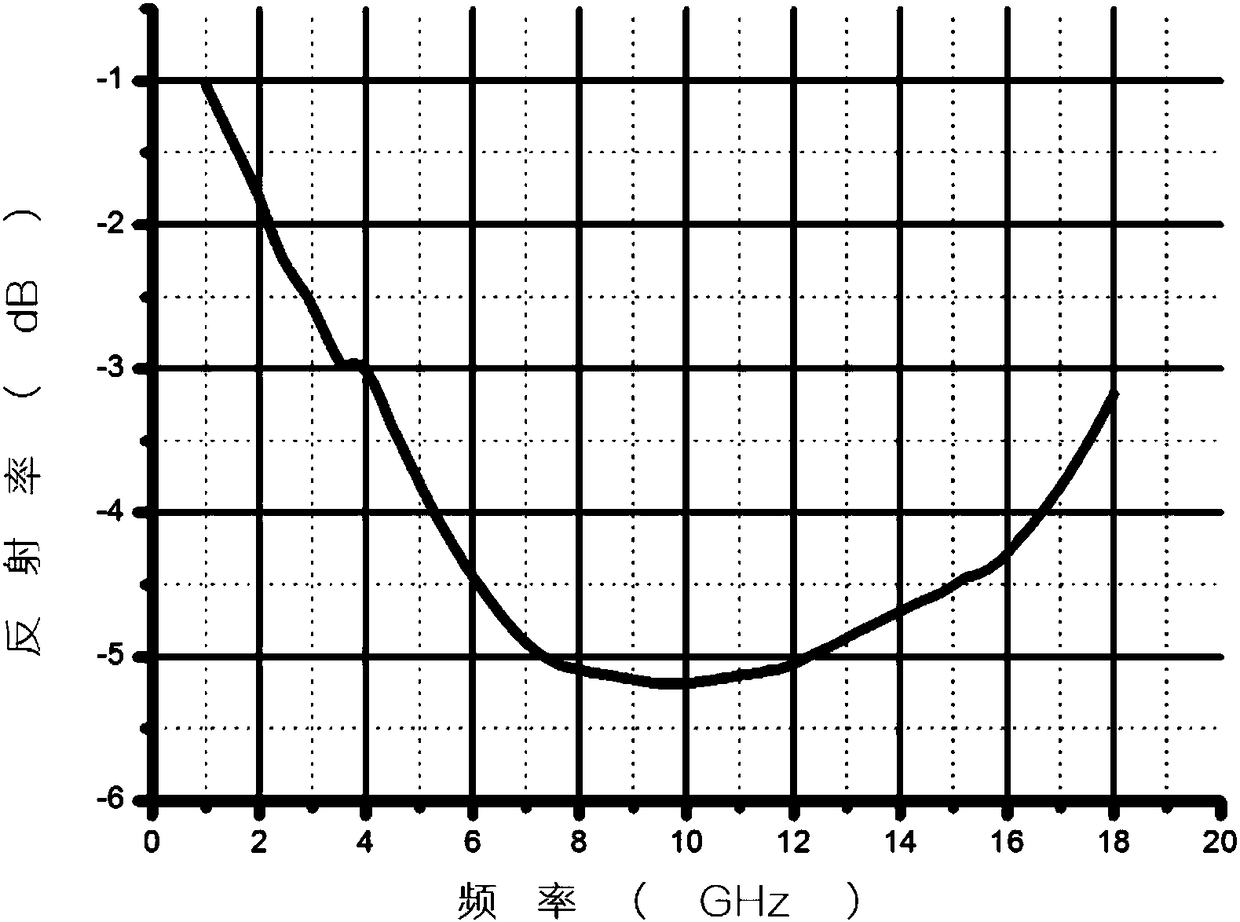

InactiveCN105504248AMeet biomechanical needsHigh viscoelasticitySuture equipmentsPharmaceutical delivery mechanismElastomerTissue repair

The invention discloses preparation and application of a linear biodegradable polyester elastomer with a controllable elasticity and shape memory effect. The linear biodegradable polyester elastomer with the controllable elasticity and shape memory effect is formed by conducting copolymerization on a caprolactone monomer containing a lateral cyclic ether structural unit and caprolactone, wherein the molar ratio of the caprolactone monomer containing the lateral cyclic ether structural unit to the caprolactone is 5:95-25:75, and the structural formula can be found in description. The viscoelasticity of the linear biodegradable polyester elastomer with the controllable elasticity and shape memory effect is remarkably improved, the elongation at break can reach 1600% and above, the elastomer can be dissolved in a conventional organic solvent, a three-dimensional porous support can be constructed conveniently through a construction technology of the porous support such as, electrostatic spinning, three-dimensional printing and phase separation, tissue engineering blood vessel scaffold materials, myocardial patches, nervous tissue engineering scaffold materials and the like are prepared, and the preparation and application of the linear biodegradable polyester elastomer can be widely applied to the fields of soft tissue engineering scaffolds, tissue repair and regenerative medicine.

Owner:JINAN UNIVERSITY

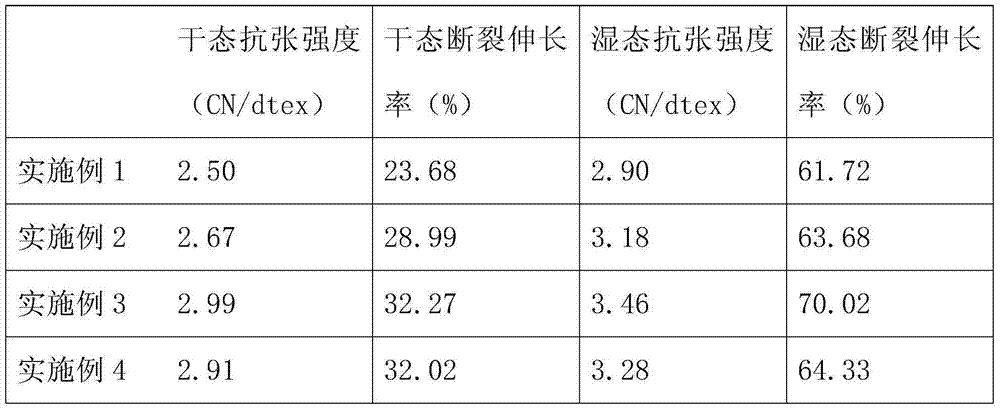

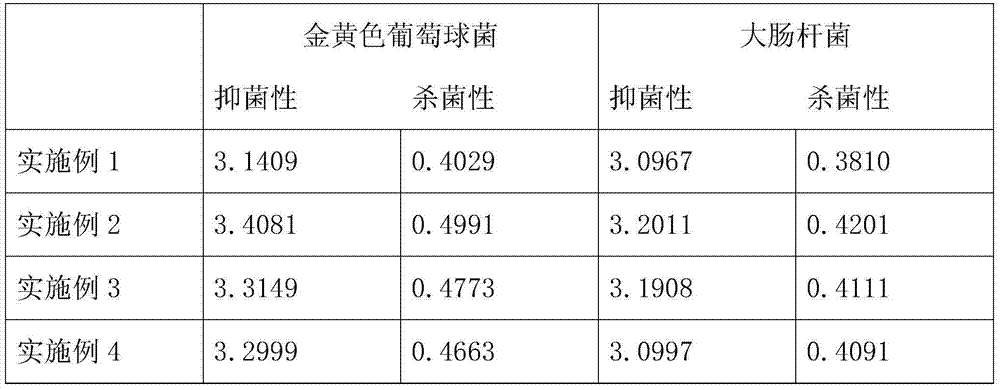

Manufacturing method of seaweed carbon fiber blended fabric

InactiveCN104213302APromote blood circulationWith insulationSucessive textile treatmentsVegetable fibres from other vegetable matterFiberCarbon fibers

The invention is suitable for the technical field of socks and discloses a manufacturing method of a seaweed carbon fiber blended fabric. The seaweed carbon fiber blended fabric is prepared by the following steps: carrying out preprocessing on seaweed, i.e. removing rhizoid and rotten leaves of the seaweed, washing clean, then cutting the seaweed into segments with lengths of 3 to 4cm and drying the seaweed segments in a drying oven at a temperature of 80 to 95 DEG C until the moisture content is 8 to 10 percent; then grinding the dried seaweed segments into the specification of 0.3 to 0.5cm in a grinder. According to the manufacturing method of the seaweed carbon fiber blended fabric, which is provided by the invention, the seaweed carbon fiber blended fabric has very high intensity and breaking elongation performance, is suitable for garments such as underwear and socks and has an excellent far infrared radiation function; the far infrared radiation can enable molecules in cells to move livelily to generate resonance and gives energy and vitality to cells; after a user wears the seaweed carbon fiber blended fabric, molecules of a human body are rubbed to generate thermal reaction so as to promote body blood circulation; the seaweed carbon fiber blended fabric has heat preservation, antibacterial and deodorizing effects, so that the seaweed carbon fiber blended fabric is beneficial for improving comprehensive performance and market competitiveness of a health care sock.

Owner:浙江久渔针纺织有限公司

Modified natural rubber composite material for cable insulation layer

InactiveCN105111656AGood resistance to heat and oxygenGood aging resistanceMaleic anhydrideCarbon black

The invention discloses a modified natural rubber composite material for a cable insulation layer. The material is prepared from the following raw materials in parts by weight: 30 to 40 parts of natural rubber, 40 to 60 parts of methyl methacrylate natural rubber, 50 to 60 parts of ethylene propylene diene monomer, 50 to 55 parts of nanosilicon dioxide, 16 to 20 parts of diatomite, 7 to 12 parts of nylon PA-66, 12 to 16 parts of calcined clay, 33 to 37 parts of white carbon black, 15 to 25 parts of carbon black, 30 to 45 parts of attapulgite, 2 to 3 parts of zinc oxide, 1.8 to 2.5 parts of sulphur, 2 to 4 parts of N-cyclohexyl-2-benzothiazole sulfenamide, 1 to 2 parts of bis(3-triethoxysilicyl propyl)-tetrasulfide, 2.5 to 3 parts of magnesium stearate, 5 to 10 parts of maleic anhydride and 2 to 5 parts of liquid carboxylated nitrile rubber. According to the modified natural rubber composite material for the cable insulation layer, provided by the invention, the cable insulation layer adopts the modified natural rubber composite material, the oxidation and heat resistant properties are good, the ageing-resistant performance is excellent, the mechanical property is good and the service life is long.

Owner:ZIBO KUAKE MEDICINE TECH

Wear-resistant and anti-ageing automotive rubber damping piece material

The invention discloses a wear-resistant and anti-ageing automotive rubber damping piece material. The wear-resistant and anti-ageing automotive rubber damping piece material comprises the following raw materials in parts by weight: 20-30 parts of natural rubber, 20-25 parts of butyl rubber, 10-15 parts of butadiene rubber, 20-25 parts of wear-resistant polyvinyl chloride masterbatches, 4-7 partsof talcum powder, 2-5 parts of a toughener, 2-4 parts of an antioxidant, 1-4 parts of an anti-ageing agent, 1-3 parts of a coupling agent, 3-9 parts of mineral oil, 3-6 parts of a maleic anhydride compatilizer, 3-7 parts of paraffin, 5-8 parts of nano barium sulfate, 2-5 parts of modified nano silicon nitride, 1-3 parts of potassium stearate, 2-5 parts of a promotor, 2-4 parts of a crosslinking agent, 1-2 parts of zinc borate and 3-7 parts of sulphur. The wear-resistant and anti-ageing automotive rubber damping piece material is reasonable in formula, the compatibility of various components isgood, and the prepared damping material has the advantages of high damping coefficient, high resilience force, damping ability, high temperature resistance, ageing resistance, creep resistance, wearresistance, good flame retardant and the like, and is suitable for automotive damping products.

Owner:ANHUI WEIWEI RUBBER PARTS GRP

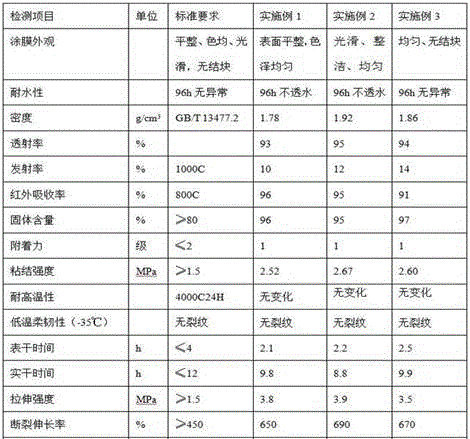

Color modified waterproof coating

InactiveCN106433458AShorten drying timeGood extensibilityProtein coatingsMulticolor effect coatingsWeather resistanceThermal insulation

The invention discloses a color modified waterproof coating which is prepared by the following steps: grinding pigment and filler into powder by a ball milling way; sequentially adding the powder together with a film forming agent, a solvent and an auxiliary into a plastic tank; stirring for 8-10min till uniform mixing; stirring for 25-28min at a speed of 1,500rpm for full dispersion; adding a film forming agent and dispersing at a high speed for 3-5min to obtain a disperse system; adding a sodium hydroxide solution and adjusting the pH value to 7.5-8.5; and mixing uniformly to obtain the waterproof coating. In the invention, the film forming agent is modified to serve as an important raw material for preparing the coating disclosed by the invention, the tensile strength and film hardness are remarkably improved, and the prepared coating has good weather resistance and waterproof property under an indoor condition and has the effects of high-temperature resistance, thermal insulation and decoration; and the preparation process is simple.

Owner:南宁马瑞娜装饰工程有限公司

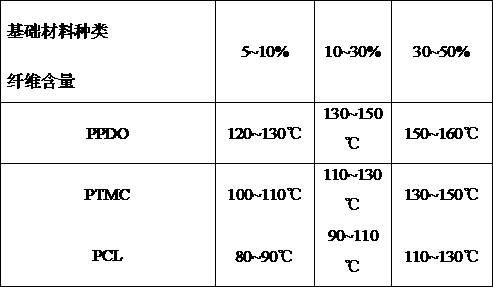

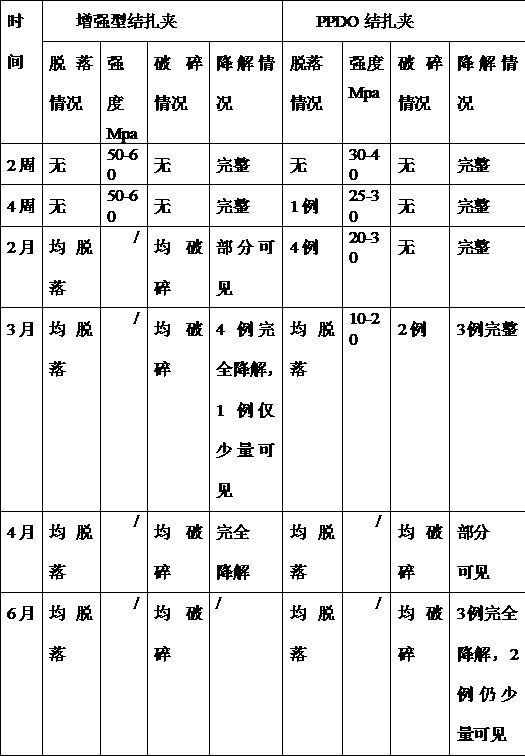

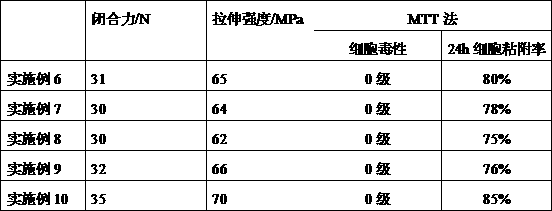

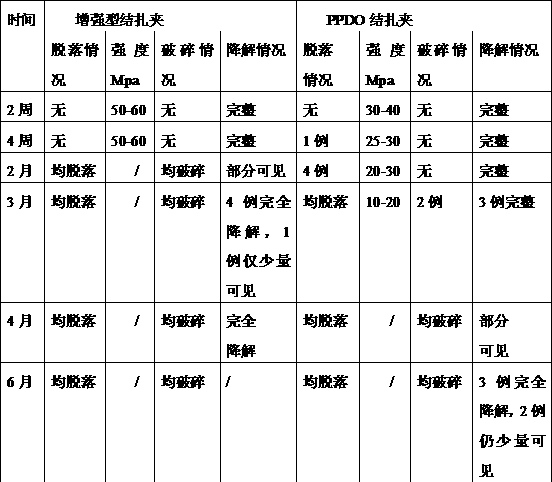

A kind of enhanced absorbable ligation clip and its preparation method

ActiveCN107812231BStrong closing forceLow melting pointSuture equipmentsPharmaceutical delivery mechanismFiberForeign matter

Owner:SHANDONG ACADEMY OF PHARMACEUTICAL SCIENCES

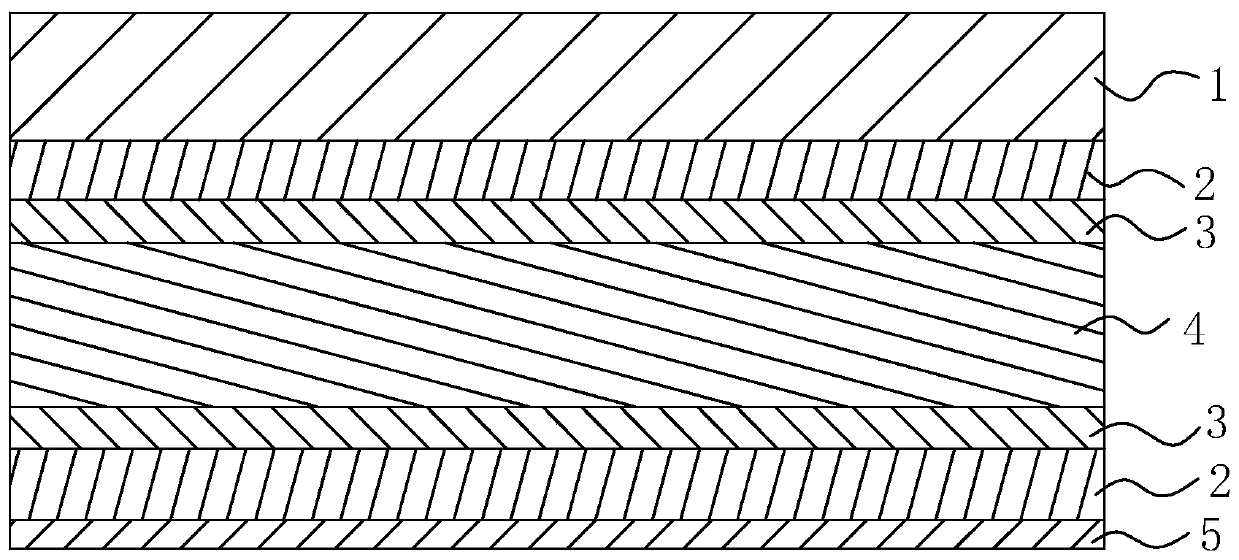

Cold stamping formed composite hard sheet for packaging medicines

InactiveCN102211431AImprove toughnessStrong toughnessFlexible coversWrappersPolymer sciencePolyvinyl chloride

The invention discloses a cold stamping formed composite hard sheet for packaging medicines. The hard sheet comprises a polyamide layer, a maleic anhydride modified polyethylene layer, an acrylic acid modified polyethylene layer, an aluminum foil layer, a dry-laminate glue layer and a polyvinyl chloride layer which are arranged in turn. By the maleic anhydride modified polyethylene layer and the acrylic acid modified polyethylene layer which are extruded in a co-extrusion mode, the aluminum foil layer and the polyamide layer to which the maleic anhydride modified polyethylene layer and the acrylic acid modified polyethylene layer are attached have higher peel strength, the whole extrusion layer is flexible and high in toughness and has high tensile strength and elongation at rupture, and a product can be effectively prevented from having problems of aluminum rupture, layer separation and the like in the cold stamping process.

Owner:SUZHOU HAISHUN PACKAGING MATERIAL

PCM plate for air conditioner outdoor unit and production process of PCM plate

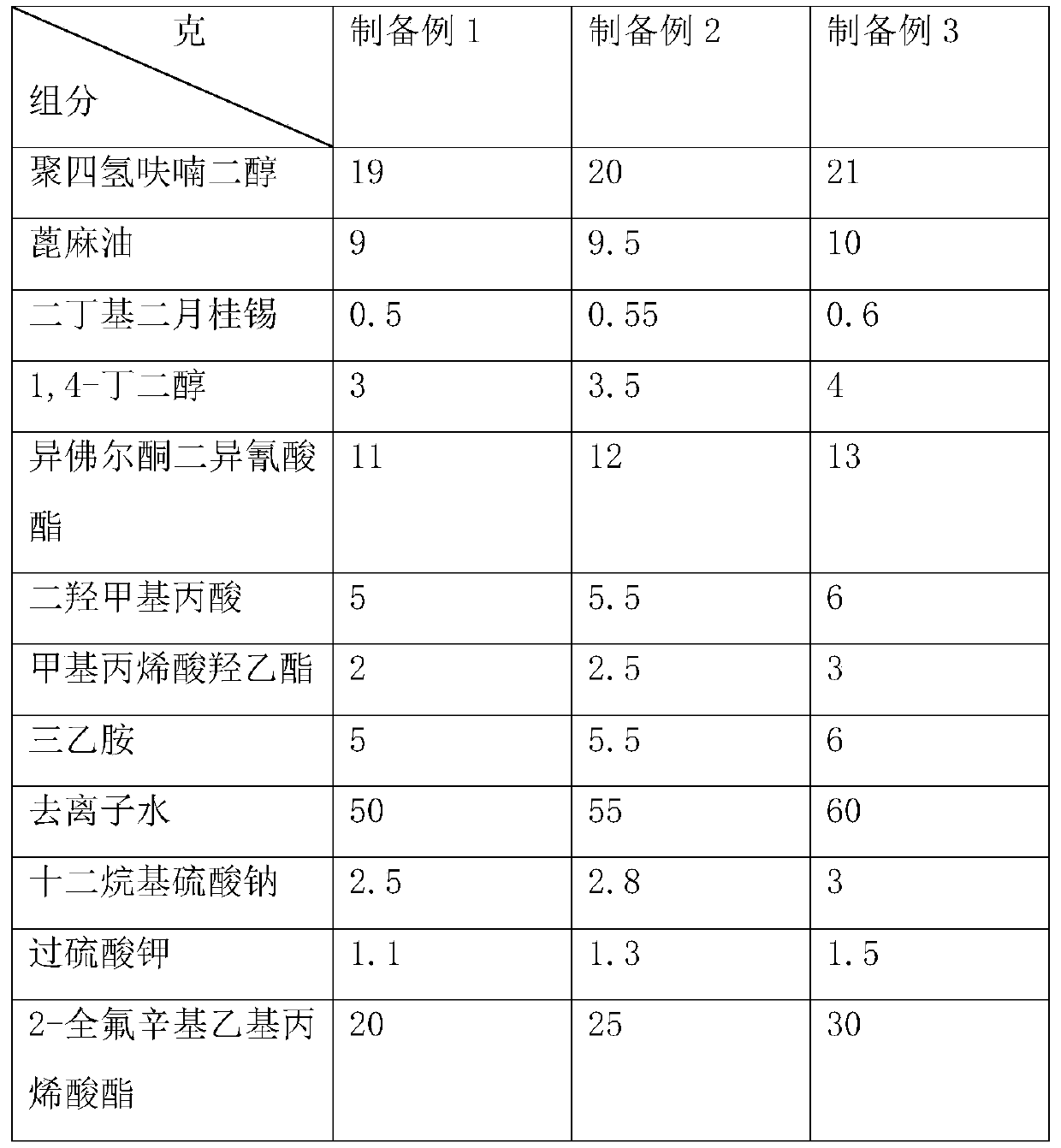

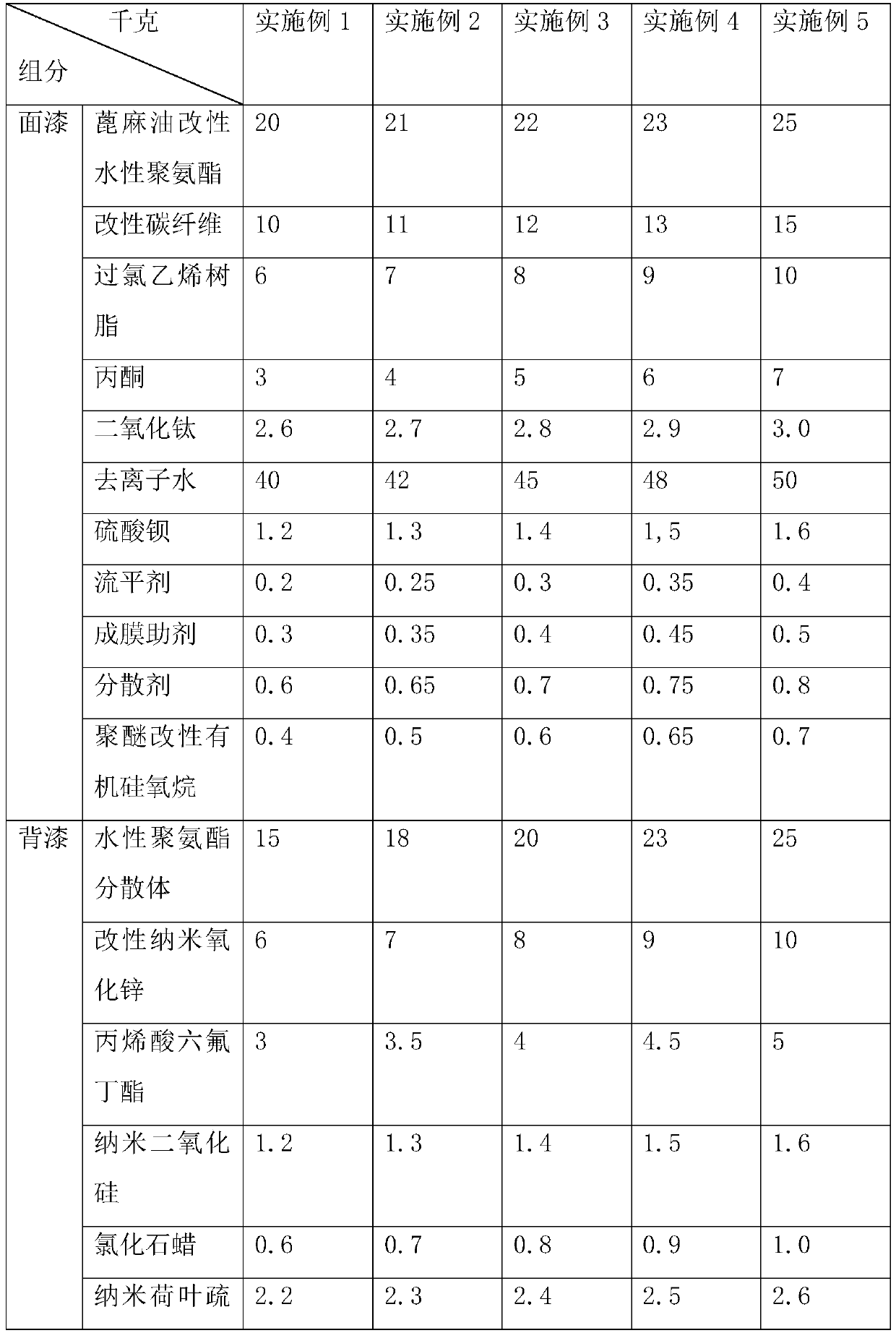

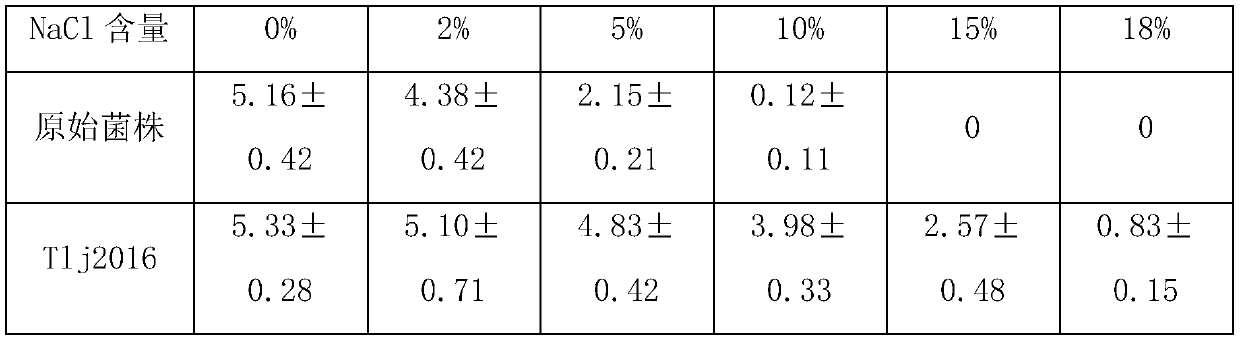

ActiveCN110484040AHigh tensile strengthStrong elongation at breakPretreated surfacesPolyurea/polyurethane coatingsFiberModified carbon

The invention discloses a PCM plate for an air conditioner outdoor unit and a production process of the PCM plate. The PCM plate for the air conditioner outdoor unit comprises a finish paint layer, aprimer layer, a passivation layer, a base plate, a passivation layer, a primer layer and a back paint layer which are sequentially stacked. The finish paint layer comprises the following components: castor oil modified waterborne polyurethane, modified carbon fibers, vinylidene chloride resin, acetone, titanium dioxide, deionized water, barium sulfate, a flatting agent, a coalescing agent, a dispersing agent and polyether modified organosiloxane; the primer layer comprises the following components: waterborne polyurethane dispersoid, modified nano zinc oxide, hexafluorobutyl acrylate, nano silicon dioxide, chlorinated paraffin, a nano lotus leaf water repellent agent, a flatting agent, a coalescing agent, a dispersing agent, polyether modified organosiloxane and deionized water. The PCM plate for the air conditioner outdoor unit has the advantages that the coating tensile property is good, the edge is not prone to cracking, and the temperature and salt mist corrosion resistance is excellent.

Owner:杭州普络飞新材料科技有限公司

Shell body material of automobile cooling pump

The invention discloses a shell body material of an automobile cooling pump. The shell body material is prepared from the following raw materials in parts by weight: 30 to 60 parts of high density polyethylene, 3 to 7 parts of dicumyl peroxide, 3 to 7 parts of clay, 4 to 6 parts of carbon black, 10 to 20 parts of modified natural wood fiber, 20 to 30 parts of phenolic resin, 2 to 4 parts of color master batch, 2 to 4 parts of disproportionated rosin, 2 to 6 parts of pine tar oil, 1 to 2 parts of an antioxidant, 2 to 4 parts of a lubricating agent and 1.5 to 2.5 parts of an antistatic agent. The shell body material of the automobile cooling pump, provided by the invention, has excellent tensile strength, high elongation at break and excellent insulativity and ageing resistance.

Owner:NINGGUO HUASHENG PLASTIC PROD

Preparation method of gum for wall

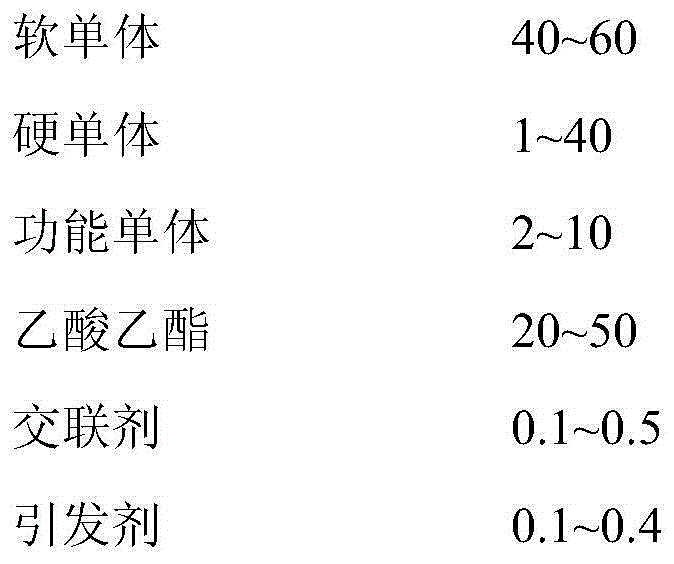

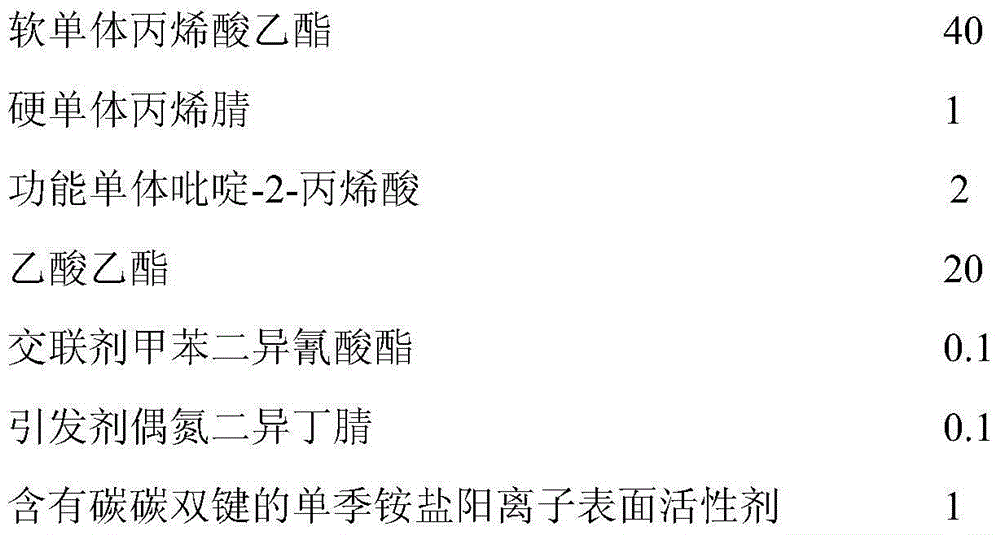

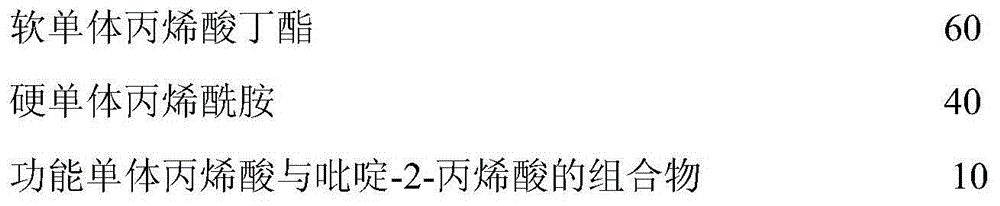

ActiveCN104694041AHigh bonding strengthImprove adsorption capacityFilm/foil adhesivesEster polymer adhesivesFunctional monomerPyridine

The invention relates to a preparation method of gum for a wall. The preparation method comprises the steps that an ink-receptive coating is coated on a printing paper layer; an acrylate pressure-sensitive adhesive layer is coated on a release layer; drying is performed; and the gum for the wall is obtained by compounding through a dry-type compounding technology. The preparation method is characterized in that an acrylate pressure-sensitive adhesive used by the acrylate pressure-sensitive adhesive layer is an acrylate pressure-sensitive adhesive for the wall, and is mainly made by copolymerization of a soft monomer, a hard monomer and a functional monomer, and the functional monomer at least comprises pyridine-2-acrylic acid. Pyridine-2-acrylic acid can form coordination with a Fe element in the wall to improve the adhesive force with the wall, so that the acrylate pressure-sensitive adhesive for the wall has the advantages of high adhesive strength, adsorption force, peeling strength and elongation at break, and good weather ability, and the gum for the wall obtained by taking the acrylate pressure-sensitive adhesive as the raw material can be applied to adhesion with the wall well.

Owner:滁州云林数码影像耗材有限公司

Impact-resistant polyurethane sieve plate for sieving ore

InactiveCN110760178AIncrease crosslink densityImprove impact resistanceCalcium silicateVulcanization

The invention relates to the technical field of polyurethane sieve plate, in particular to an impact-resistant polyurethane sieve plate for sieving ore, which comprises seven steps of modification ofactive calcium silicate, preparation of composite filler, preparation of prepolymer, chain extension of prepolymer, casting molding, demoulding vulcanization and low temperature curing. The polyurethane sieve plate prepared by the invention is prepared by inserting active calcium silicate into the long chain of polyphenol oxide resin, as that polyphenol oxide resin is uniformly distributed in thepolyurethane, crosslinked networks and a large number of hydrogen bonds are formed in the polyurethane, which greatly increases the impact resistance of the polyurethane sieve plate, and the compositepowder does not reduce the wear resistance of the polyurethane sieve screen while enhancing the impact resistance of the polyurethane sieve screen, so that the service life of the polyurethane sievescreen when screening ores is as high as 6-7 months.

Owner:太和县绿源滤材有限公司

Layered broadband radar wave-absorbing sheet and its preparation method

ActiveCN108092006BAbsorption BandwidthImprove microwave absorptionLamination ancillary operationsSynthetic resin layered productsWideband radarMedical equipment

The invention discloses a layered broadband radar absorbing plate. The absorbing plate is a multilayer absorbing film. The multilayer absorbing film has five layers which are a first layer of a spherical carbonyl iron film, second and third layers of flaky carbonyl iron films, fourth and fifth layers of sheet Fe-Si-Al films from top to bottom in sequence. The invention also discloses a manufacturing method of the above-mentioned absorbing plate. The layered broadband radar absorbing plate of the present invention utilizes the principle of electromagnetic matching, the stress orientation technology, and the production technology of coating, rolling and vulcanization comprehensively. The finished product is characterized by high microwave absorption rate, a wide absorption frequency band, athin thickness, small surface density, high elongation at break, strong adhesion, high and low temperature resistance, flame retardance, easy usage, etc., and has wide application prospects in microwave stealth transformation of radar, communications equipment, satellite navigation, electrical equipment, notebooks, base stations, medical equipment and other electronic industries and weapons and equipment, and especially the stealth transformation of aerospace vehicles.

Owner:南京冠旭新材料科技有限公司

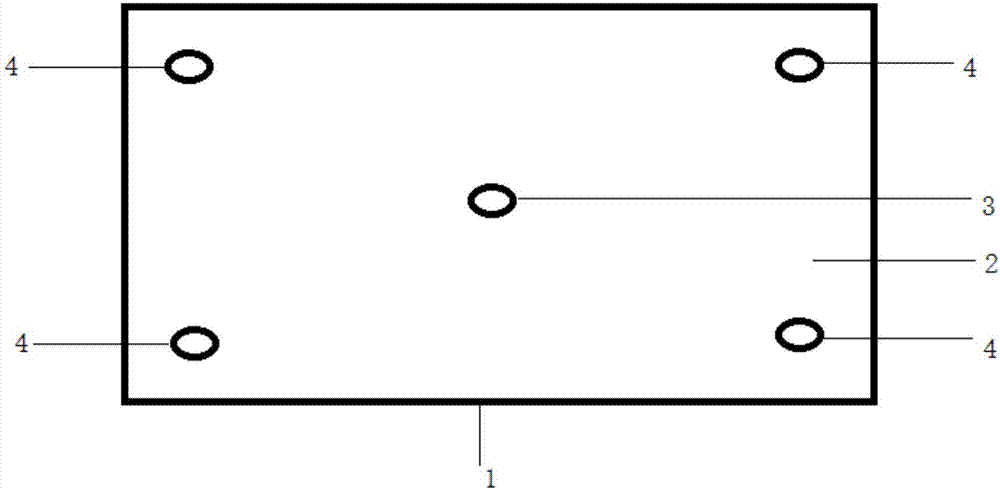

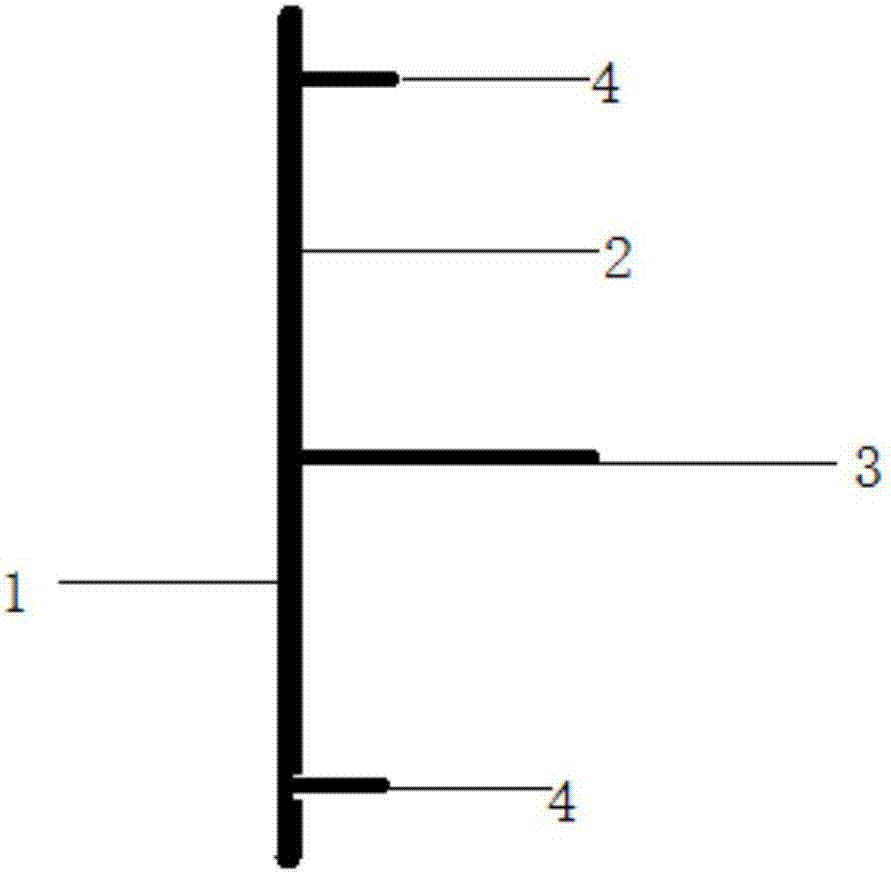

Enhanced type adsorbable ligation clip and preparation method thereof

ActiveCN107812231AStrong closing forceLow melting pointSuture equipmentsPharmaceutical delivery mechanismFiberPolyester

The invention discloses an enhanced type adsorbable ligation clip and a preparation method thereof. The ligation clip is prepared from a base material and nano staple fibers, the nano staple fibers are uniformly dispersed in the base material in a manner of keeping a crystalline form, and the mass percent of the nano staple fibers in a composite material is 5% to 50%. The enhanced type adsorbableligation clip disclosed by the invention has good biocompatibility and biodegradability; after the ligation clip is used, phenomena such as tissue adhesion, infarction and sepsis cannot be caused; during degradation, polyester materials of the nano staple fibers such as polyglycollide or polylactide are relatively high in hydrolysis speed, and a regional acidic environment can be generally formedinside the ligation clip in 30 days, so that the degradation of the base material is accelerated, and the absorption time of the base material is greatly shortened to 90 days from original 180 days; the generation of foreign-matter adverse reaction is absent, so that the clinical requirements of medical materials can be met.

Owner:SHANDONG ACADEMY OF PHARMACEUTICAL SCIENCES

Method for producing plastic tray by utilizing hollow blow molding machine

The invention discloses a method for producing a plastic tray by utilizing a hollow blow molding machine. The method comprises the steps of sealing an original air outlet of a blowing hole in the bottom of a traditional front die of the plastic tray, and arranging five blowing needles on the forming surface of the front die by utilizing a ventilation channel of the original bottom blowing hole; clamping the bottom of a tubular hollow blank when the blank is discharged, beginning to assemble, preblowing air to the hollow position of the tubular hollow blank through a blowing port in an extruding machine at the same time, stopping preblowing air when the tubular hollow blank is expanded to the set size, and continuing assembling; at the time, the five blowing needles are slowly close to the hollow blank, firstly, the hollow blank is punctured by the longest central blowing needle so as to blow air, and secondly, the hollow blank is punctured by the corner blowing needles with the same length at four corners so as to blow air, so that simultaneous blowing from five side surfaces is realized, and the tray blank is uniformly and closely adhered to the surface of a die cavity instantly. Finally, the method for producing the plastic tray, which has the advantages of uniformity in wall thickness, high intensity, low raw material consumption, low cost, stable quality and high efficiency, is provided.

Owner:吴忠市恒通塑料制品有限公司

Cable material

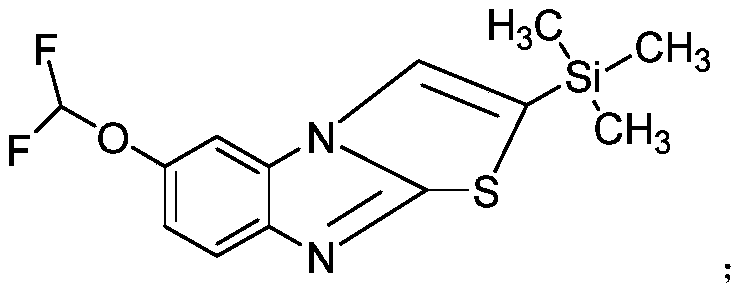

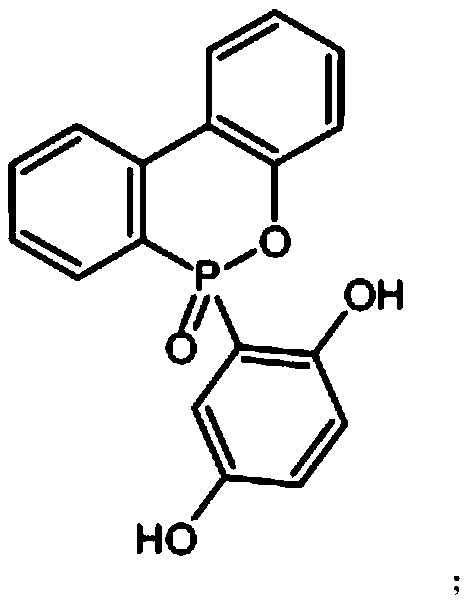

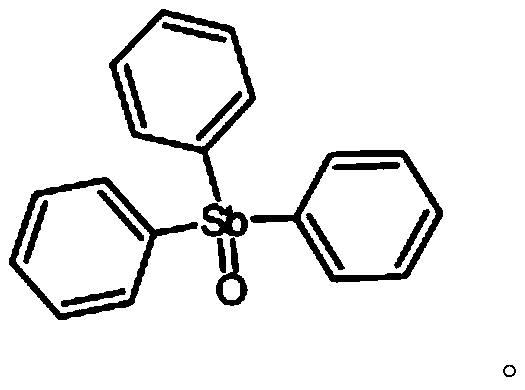

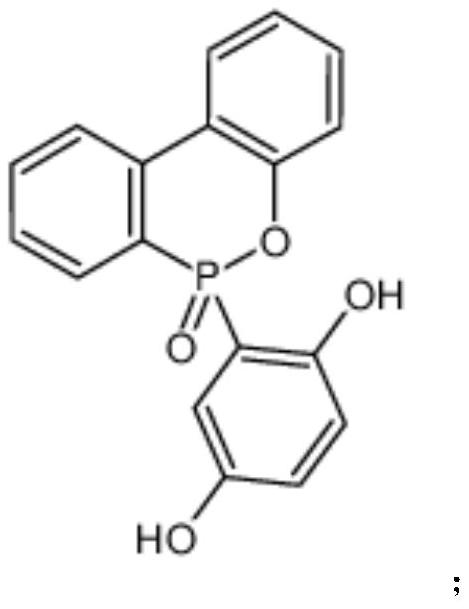

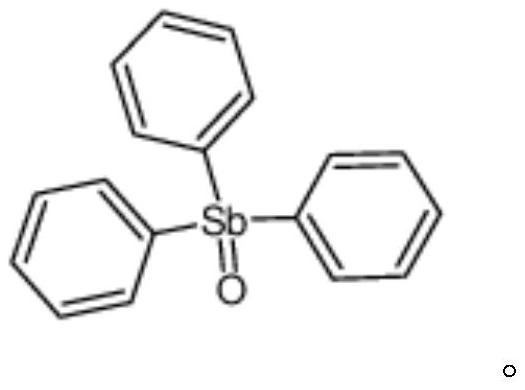

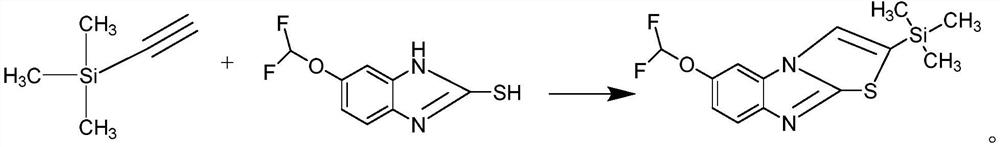

ActiveCN111117136AGood heat resistanceImprove mechanical propertiesSilicon organic compoundsPlastic/resin/waxes insulatorsBenzimidazoleMaleic anhydride

The invention discloses a cable material. The cable material is prepared by taking modified polyethylene and ethylene propylene diene monomer as base materials, adding auxiliaries such as a flame retardant, a stabilizer, an anti-aging agent and the like at the same time and performing a reaction, wherein the modified polyethylene is prepared by taking polyethylene as a raw material, tert-butyl peroxymaleate as an initiator and sodium dodecyl benzene sulfonate as a catalyst and adding a modifier; the modifier is selected from a mixture of vinyltrimethoxysilane, 2,3-bis (2,4,5-trimethyl-3-thiophene)maleic anhydride and (3,3,3-trifluoropropyl)trimethoxysilane; and the flame retardant is selected from a mixture of 6-(difluoromethoxy)-2-(trimethylsilyl)benzo[4,5]imidazo[2,1-b]thiazole and 10-(2,5-dihydroxyphenyl)-10-hydrogen-9-oxa-10-phosphaphenanthrene-10-oxide and triphenylantimony oxide. The prepared cable material not only has high tensile strength and elongation at break, but also hashigh flame retardant property, and still has high tensile strength and elongation at break even after being subjected to thermal aging and sunlight aging treatment.

Owner:WENZHOU UNIVERSITY

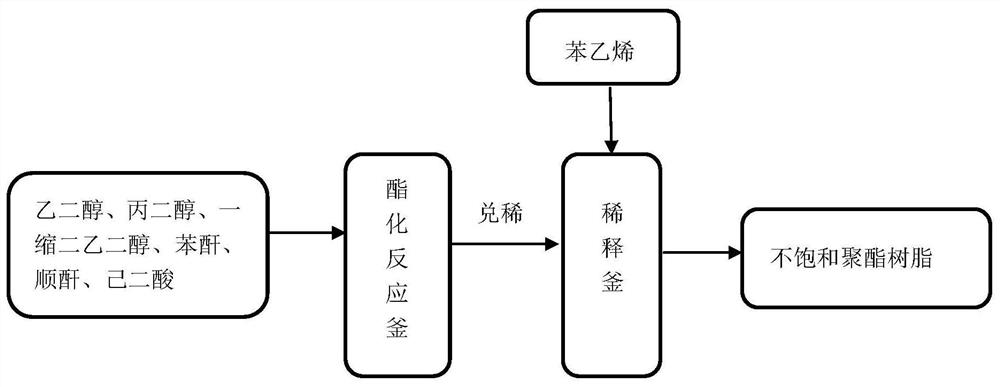

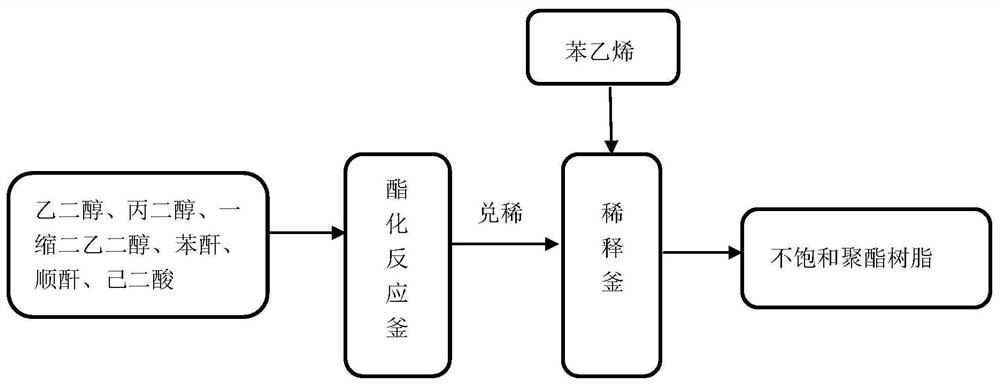

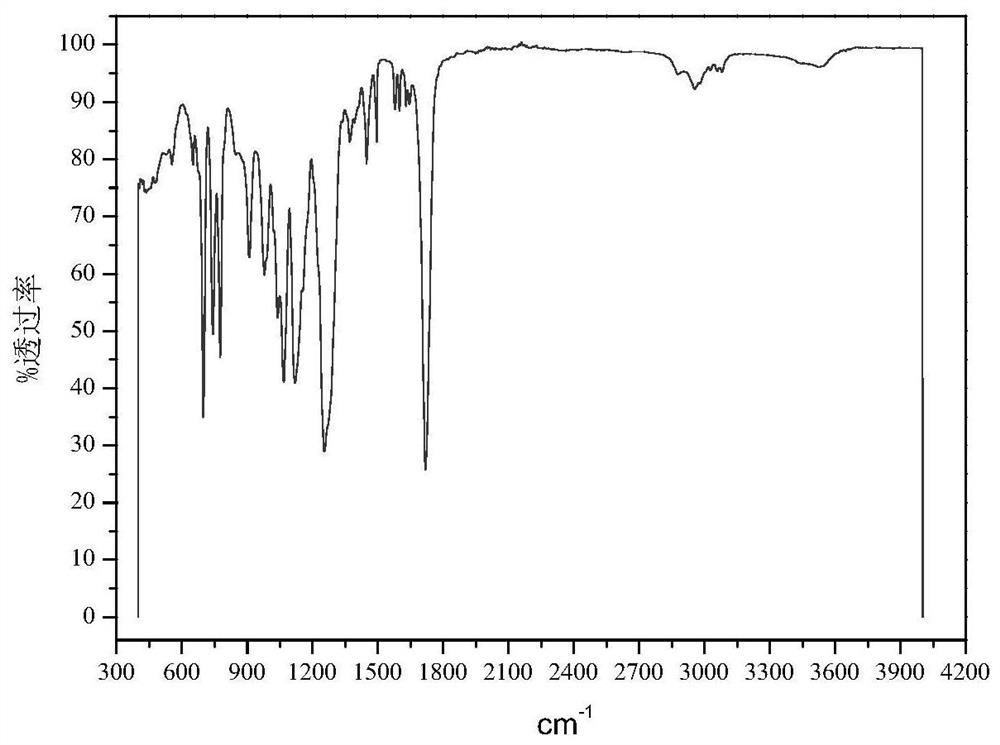

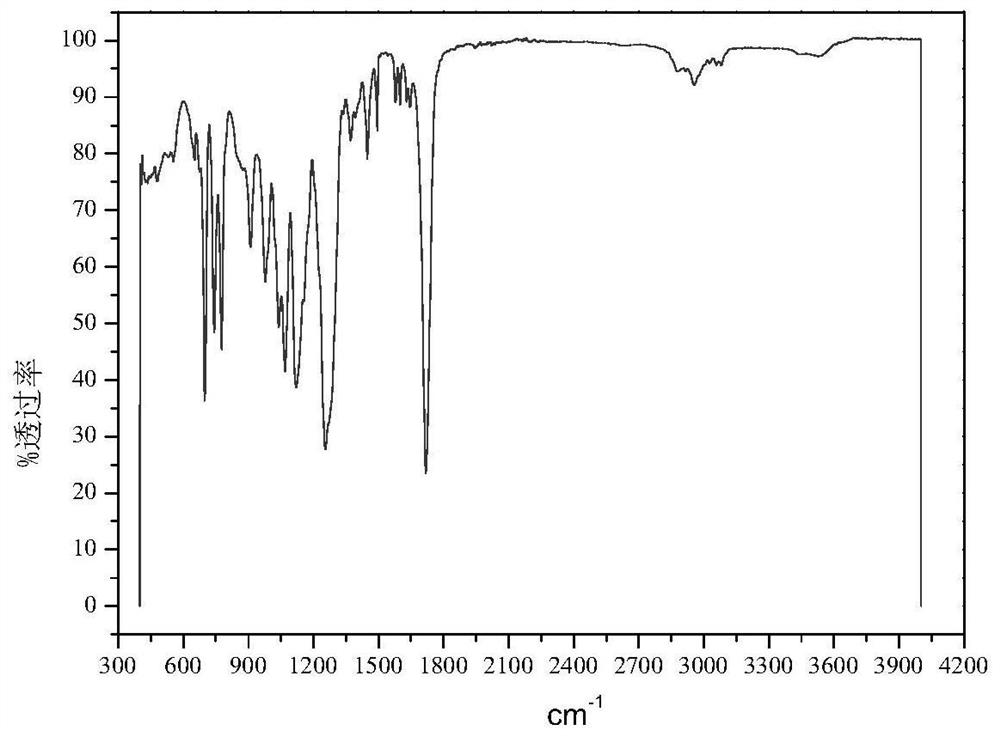

High-toughness polyester resin and synthetic method thereof

ActiveCN111748083AHigh heat distortion temperatureHigh elongation at breakPolymer scienceThermal deformation

The invention belongs to the technical field of polymer polyester materials, and particularly relates to high-toughness polyester resin and a synthesis method thereof. The polyester resin is preparedfrom the following raw materials in percentage by mass: 20 to 40 percent of dihydric alcohol, 30 to 50 percent of binary acid and / or anhydride, 20 to 40 percent of diluted solvent and 0.01 to 0.1 percent of an auxiliary agent. The high-toughness polyester resin has the advantages of lower viscosity, higher reaction activity, strong adhesive property, high thermal deformation temperature, high elongation at break and high strength of a resin casting body. The polyester resin is used for manufacturing artificial marble crushed aggregate bonding, artificial quartz stone plates and the like, and has the advantages of favorable wettability with fillers, favorable toughness and excellent mechanical strength.

Owner:山东凯威尔新材料有限公司

Cork polyurethane sole material and preparation method thereof

The invention discloses a cork polyurethane sole material. The sole material comprises the following raw materials in parts by weight: 3-4 parts of azodicarbonamide, 30-35 parts of saw dust, 80-100 parts of polycarbonate diol, 60-70 parts of isophorone diisocyanate, 1-2 parts of an initiator, 0.5-1 part of a catalyst a, 0.1-0.2 part of color paste, 2-4 parts of trimethylamine and 20-30 parts of anelastic dispersion liquid. The sole material disclosed by the invention has very strong impact strength and elongation at break, and is soft in texture, good in wear resistance, low in cost and highin quality.

Owner:泉州邦尼生物科技有限公司

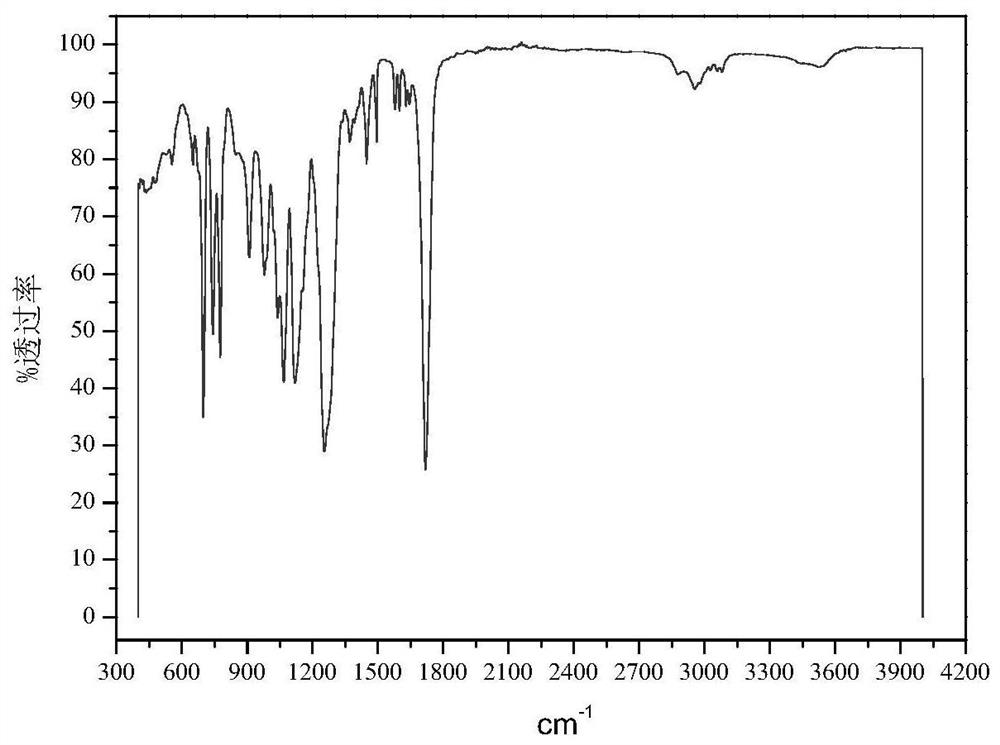

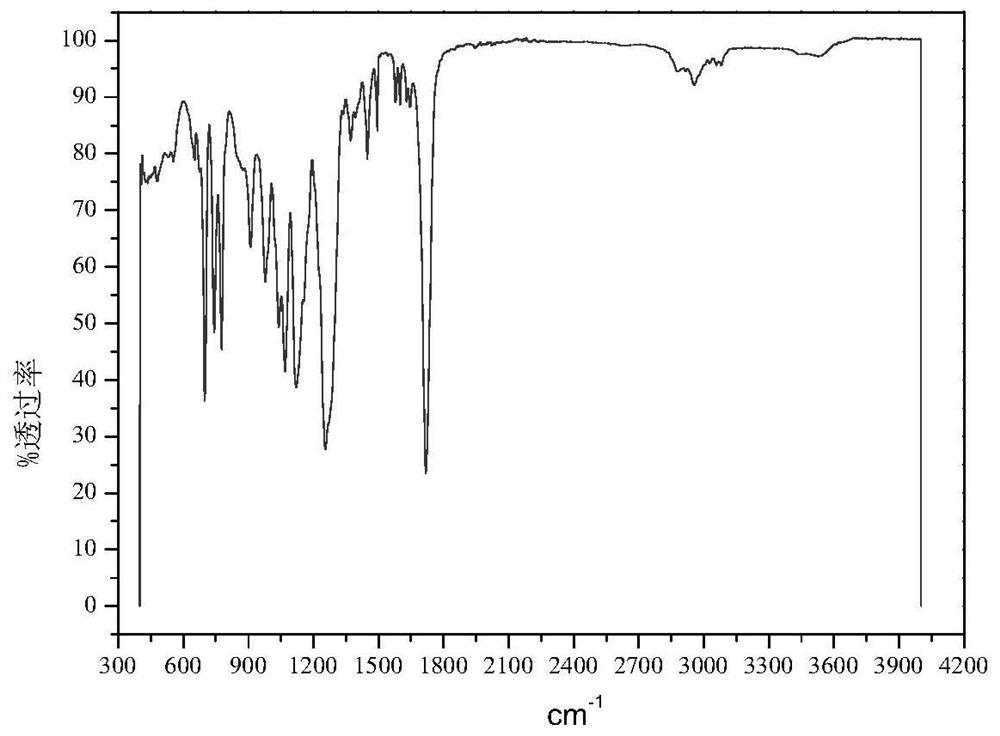

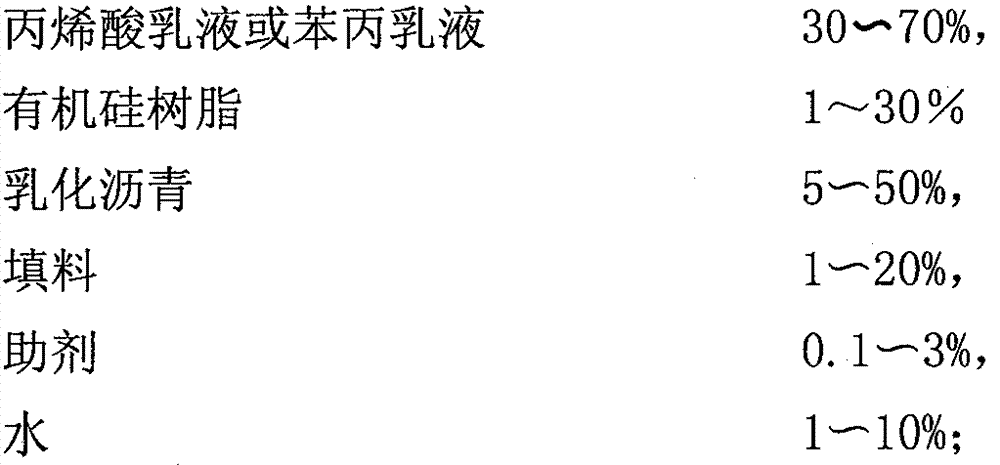

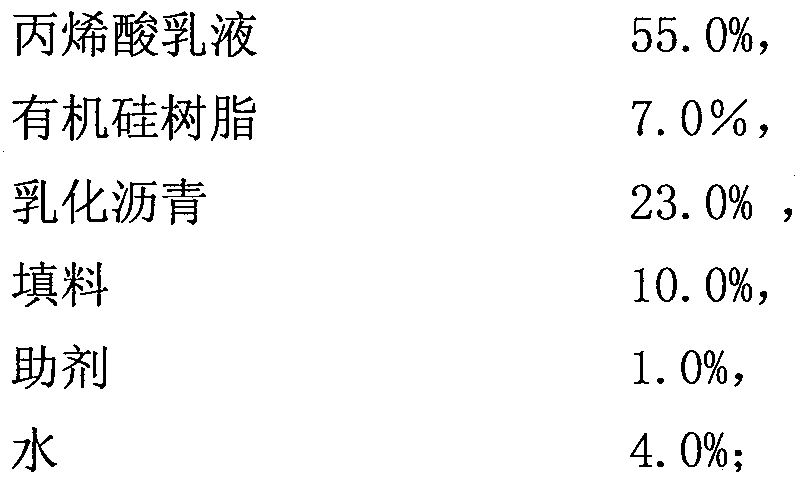

Water-emulsion organic silicon composited acrylic acid modified asphalt cement-base waterproof coating and preparation method thereof

The invention relates to a cement-base waterproof coating for water proofing, seepage proofing and liquid proofing of roads and bridges and preparation method thereof. The invention is characterized in that the water-emulsion organic silicon composited acrylic acid modified asphalt cement-base waterproof coating is composed of component A and component B in weight ratio of 1:0.5-1.5; wherein the component A contains the following raw materials by weight percent: 30-70% of acrylic emulsion or styrene-acrylic emulsion, 1-30% of organic silicon resin, 10-50% of emulsified asphalt, 1-20% of filler, 0.1-3% of auxiliary agent and 1-10% of water; and the component B contains the following raw materials by weight percent: 70-100% of cement and 0-30% of filler. The invention has the characteristics of strong adhesive force with foundation, high tensile strength, high elongation at break, strong adaptability, favourable shearing performance, low cost and being environmentally friendly.

Owner:ANHUI ZHONGYI NEW MATERIAL TECH CO LTD

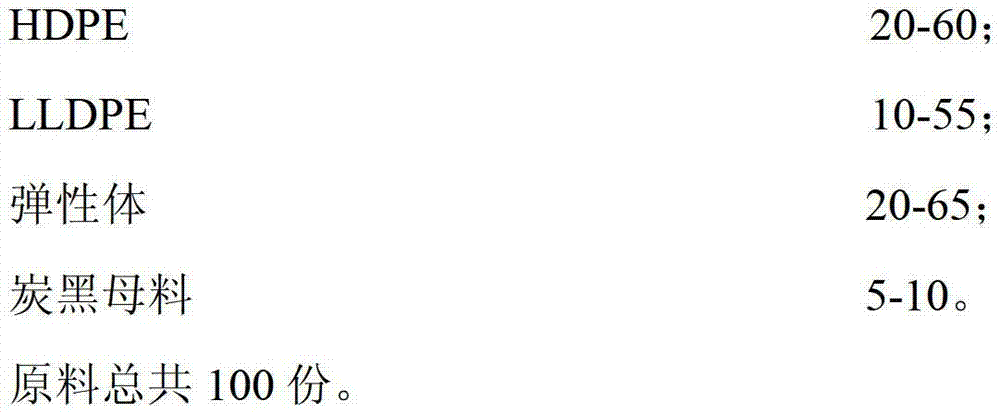

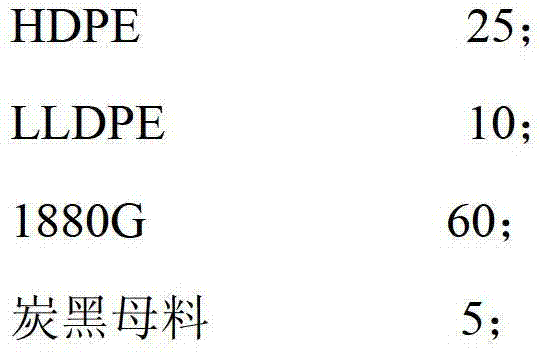

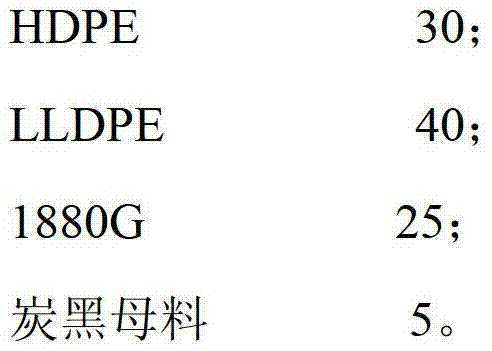

High-flexibility geomembrane and preparation method for same

InactiveCN103214717BGood flexibilityImprove securitySynthetic resin layered productsElastomerGeomembrane

The invention relates to a high-flexibility geomembrane and a preparation method for the same. The high-flexibility geomembrane comprises the following raw materials in percentage by weight: 20-60% of HDPE (high density polyethylene), 10-55% of LLDPE (linear low density polyethylene), 20-65% of elastomer, and 5-10% of carbon black master batch, wherein the total percentage of the raw materials is 100. The preparation method comprises the following steps of: weighing and uniformly mixing the raw materials aforementioned according to a formula; pouring the raw materials in an extruder, and melting and uniformly mixing in the extruder; conveying the raw materials in a three-layer co-extrusion extruder, and extruding from a circular die orifice; blowing up via air, and cooling to form a tubular membrane; and splitting, flattening and rolling to obtain the product. The high-flexibility geomembrane disclosed by the invention is greatly improved in elongation at break, puncture resistance, cold brittleness resistance and bending resistance; and the geomembrane is improved in safety during a use process.

Owner:SHANDONG TIANHE PLASTIC

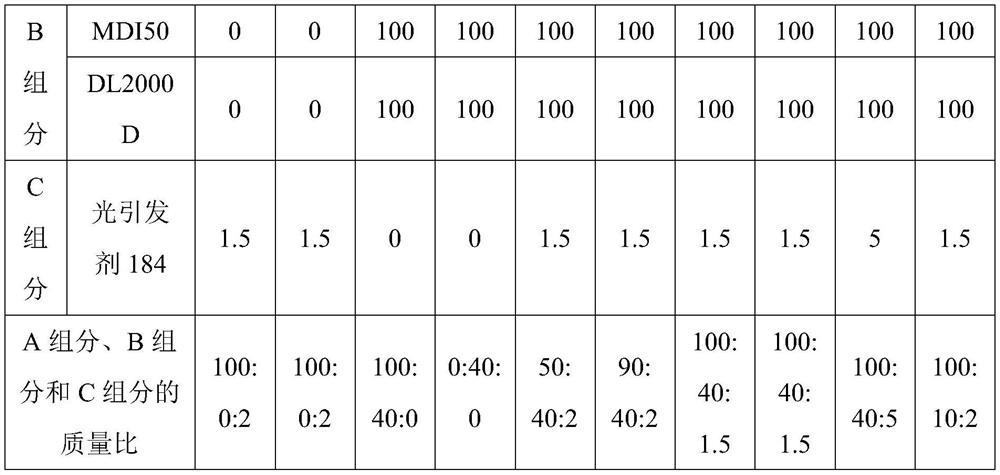

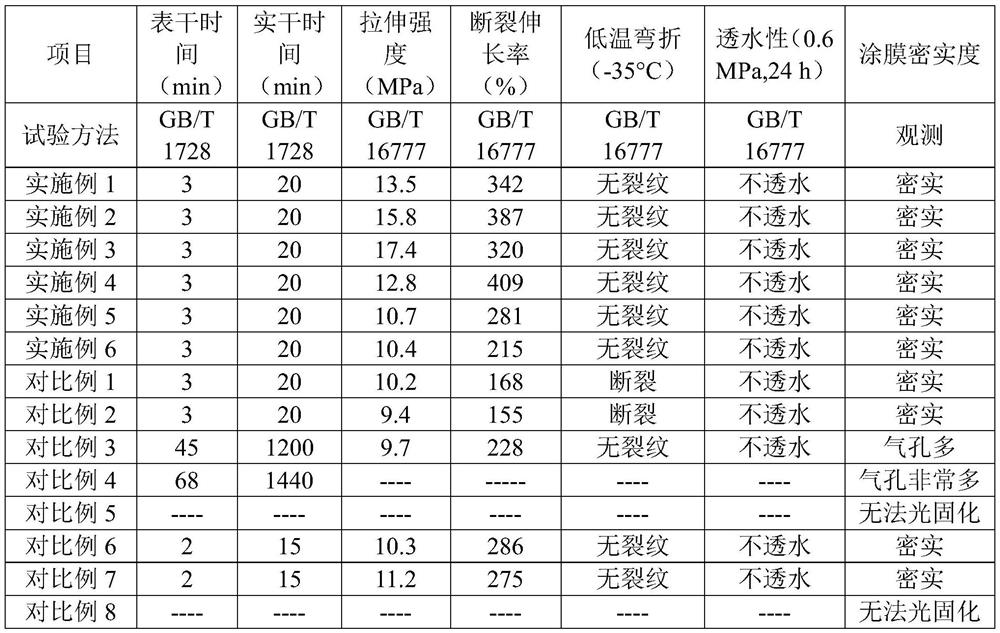

A kind of light curing polyurethane coating and its preparation method and application

ActiveCN110746877BSlow reaction rateShort curing timeFireproof paintsAnti-corrosive paintsPolymer sciencePhotopigment

The invention provides a light-cured polyurethane coating and a preparation method and application thereof. The coating is composed of the following raw material components: component A includes by weight: 60-80 parts of polyurethane acrylate, 10-20 parts of reactive monomer diluent, 1-20 parts of amino resin, and 0.05-10 parts of pigment and 10-30 parts of filler; B component includes by weight: 40-100 parts of isocyanate and 40-100 parts of polyol; C component is a photoinitiator. The light-curable polyurethane coating of the invention can form a dense and non-porous elastic coating film with high mechanical strength, heat and cold resistance, corrosion resistance and aging resistance after being cured.

Owner:北京博瑞众诚科技有限公司 +1

Automobile steering gear bellows dust shield material

The invention discloses an automobile steering gear bellows dust shield material, raw materials of which comprise (by weight): 20-50 parts of high density polyethylene, 1-5 parts of dimethylamino propylanmine, 5-15 parts of modified natural wood fiber, 2-4 parts of kapok fiber, 1-5 parts of nano-silica, 15-25 parts of clay, 1-4 parts of diisononyl phthalate, 1-2 parts of phosphate, 1-2 parts of color master batch, 1-3 parts of a lubricant, 0.5-1.5 parts of an antioxidant and 1-2 parts of an antistatic agent. The automobile steering gear bellows dust shield material has excellent tensile strength, high elongation at break and excellent insulating property and aging resistance.

Owner:NINGGUO HUASHENG PLASTIC PROD

A kind of modified nano barium sulfate reinforced polypropylene membrane and preparation method thereof

The invention relates to a polypropylene film reinforced by modified nano barium sulfate and a preparation method of the polypropylene film and belongs to the technical field of functional packaging materials. The polypropylene film is prepared by using the modified nano barium sulfate as the toughening agent and organic montmorillonite and maleic anhydride grafted polyethylene as the compatibilizer, adding certain reinforcing agent and using PP as base material through blowing. The reinforced composite polypropylene film prepared by the method is good in heat resistance, high in barrier property, high in tensile property, high in breaking elongation rate and good in anti-aging performance, has certain flame retardance, and is widely applicable to fields such as daily necessities and household appliances.

Owner:WUXI JIATAI TECH

Cold stamping solid pharmaceutical composite hard tablet

ActiveCN104589728BReduce transmittanceImprove the bonding force between layersFlexible coversWrappersWater vaporPolyamide

The invention relates to a cold-stamping composite hard tablet for solid medicine and belongs to the technical field of pharmaceutical packaging materials. The cold-stamping composite hard tablet for solid medicine of the invention comprises a polyamide layer, an aluminum foil layer and a polyvinyl chloride layer which are sequentially arranged, wherein a glue layer is arranged between the aluminum foil layer and the polyvinyl chloride layer. According to the invention, each surface of the aluminum foil layer comprises an aluminum phosphate film and a rough layer, the surface of the aluminum foil layer is coated with a polyurethane resin layer and the polyurethane resin layer is located between the aluminum foil layer and the polyamide layer; a maleic anhydride modified polyethylene layer and an acrylic acid modified polyethylene layer are orderly arranged between the polyamide layer and the aluminum foil layer; and adhesive layers are both arranged between the acrylic acid modified polyethylene layer and the polyurethane resin layer and between the aluminum foil layer and the polyurethane resin layer. According to the invention, the glue density of the glue layer is 4.9-5.1g / cm<3>, the thickness of the polyamide layer is 28-32 mu m, the thickness of the aluminum foil layer is 48-53 mu m, the thickness of the polyurethane resin layer is 52-58 mu m and the total thickness of the composite hard tablet is 140-143 mu m. The composite hard tablet of the invention has long service life and small vapor and oxygen transmittance.

Owner:宁波龙安包装科技有限公司

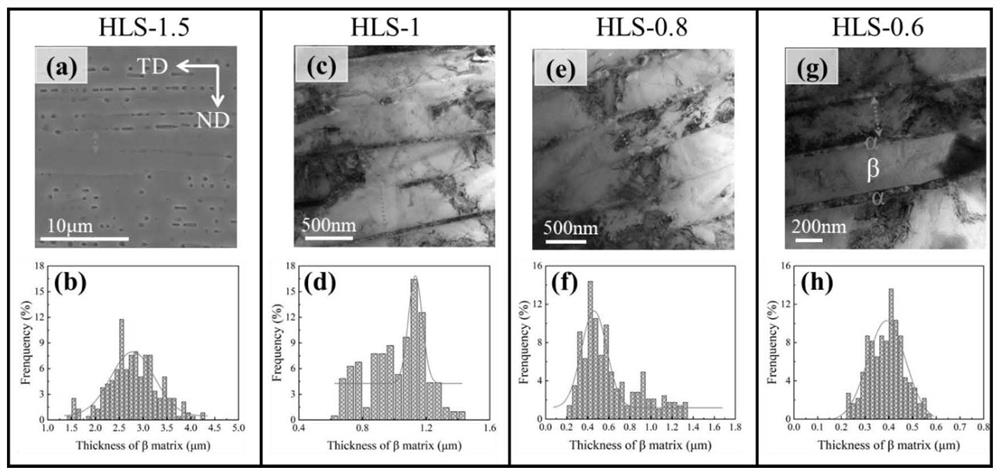

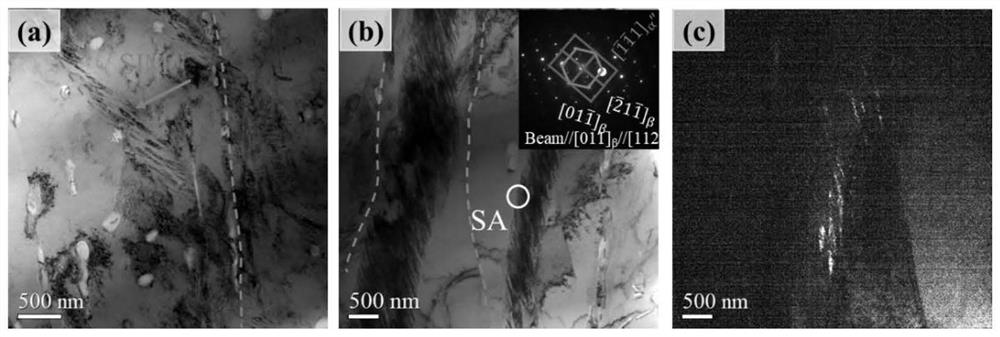

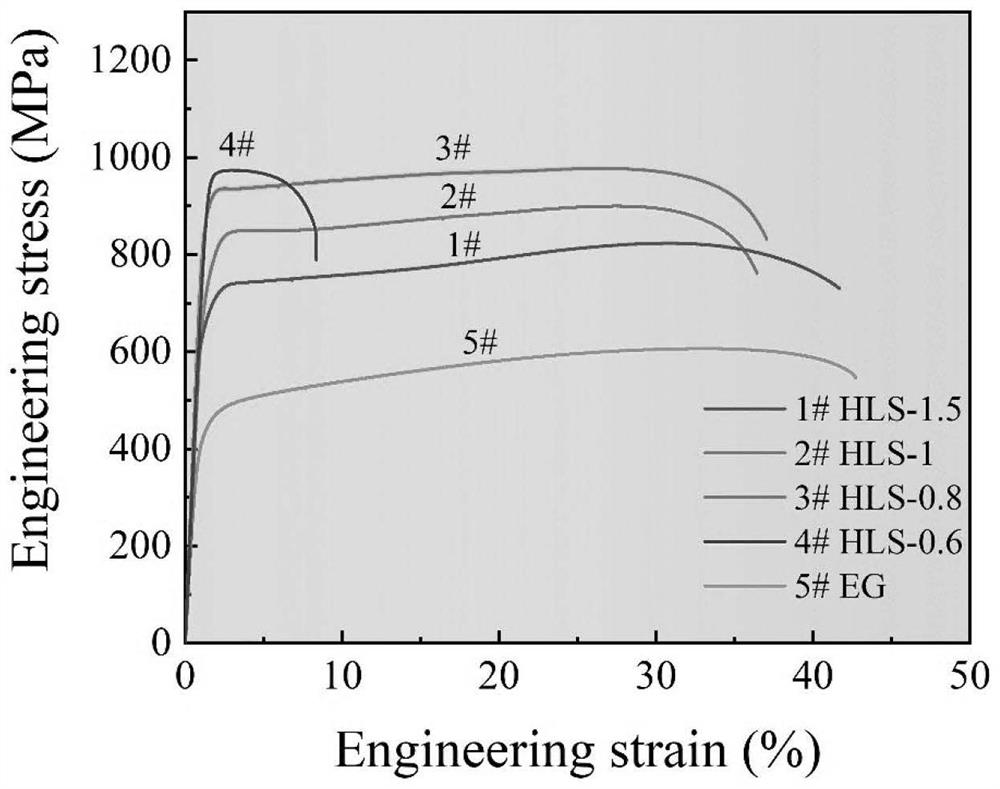

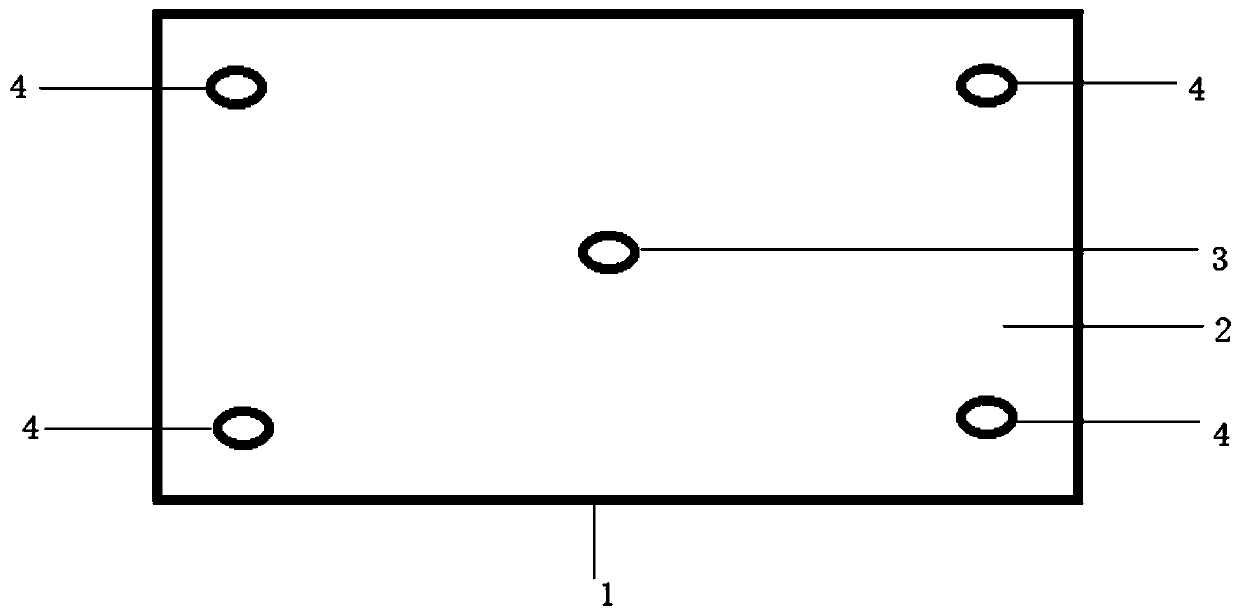

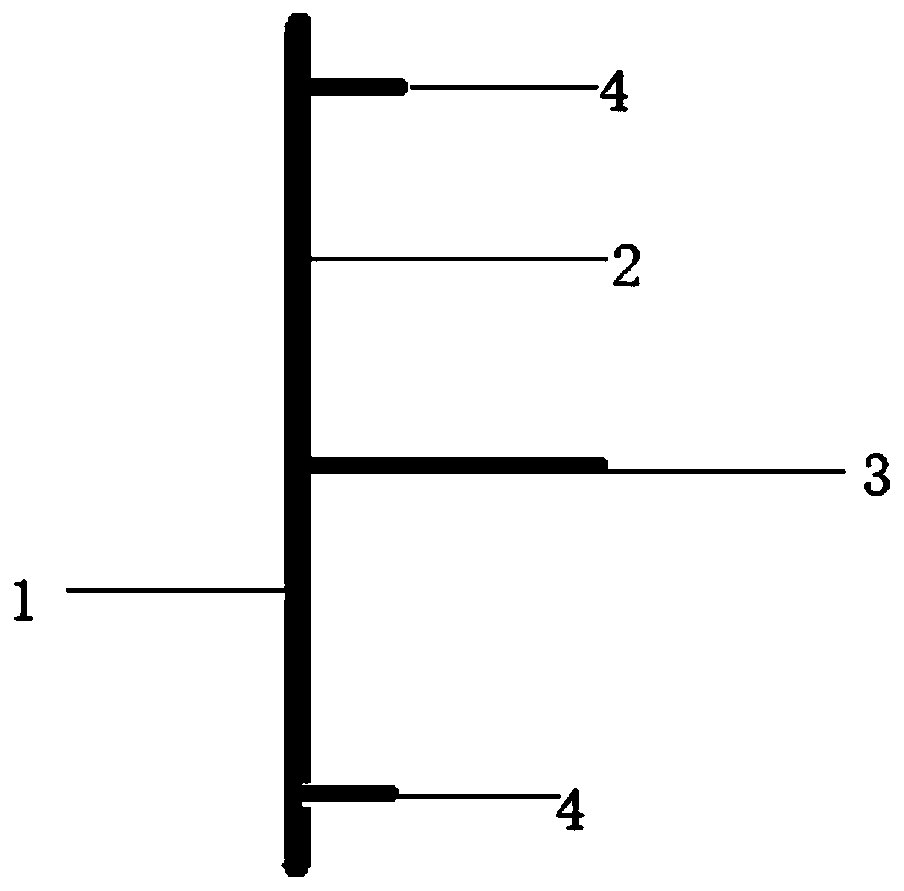

Double-phase high-strength high-plasticity titanium alloy with layered structure and preparation method of double-phase high-strength high-plasticity titanium alloy

InactiveCN113943911AHigh elongation at breakHigh strength elongation at breakDouble phaseUltimate tensile strength

The invention discloses a double-phase high-strength high-plasticity titanium alloy with a layered structure and a preparation method of the double-phase high-strength high-plasticity titanium alloy. According to the method, an alloy is subjected to heat preservation for 1 h to 2 h in a beta single-phase region at a temperature of 1000 DEG C to 1100 DEG C in a muffle furnace and then quenched to a room temperature so as to obtain a uniform beta phase, the obtained alloy is heated again to a temperature above a phase transformation point, heat preservation is conducted for 10 min to 20 min, then rolling is conducted, and finally, a plate obtained through rolling is subjected to heat preservation for 1 min to 2 min at a temperature 5 DEG C to 10 DEG C higher than the phase transformation point and then quenched to the room temperature, so as to obtain a double-phase TRIP titanium alloy with the layered structure. According to the double-phase TRIP titanium alloy with the layered structure prepared through the method, optimal performance can be achieved, which is a mechanical performance combination of yield strength of 875 MPa and an elongation at break of 36%, the yield strength of the titanium alloy is twice as high as yield strength of a conventional TRIP metastable-state beta titanium alloy, plasticity is hardly lost, and based on the characteristics, the alloy has great competitive advantages in the TRIP metastable-state beta titanium alloy.

Owner:XI AN JIAOTONG UNIV

A method for producing plastic trays using a hollow blow molding machine

ActiveCN106926439BSmall toleranceStrong impact resistanceDomestic articlesBlow moldingMechanical engineering

The invention discloses a method for producing a plastic tray by utilizing a hollow blow molding machine. The method comprises the steps of sealing an original air outlet of a blowing hole in the bottom of a traditional front die of the plastic tray, and arranging five blowing needles on the forming surface of the front die by utilizing a ventilation channel of the original bottom blowing hole; clamping the bottom of a tubular hollow blank when the blank is discharged, beginning to assemble, preblowing air to the hollow position of the tubular hollow blank through a blowing port in an extruding machine at the same time, stopping preblowing air when the tubular hollow blank is expanded to the set size, and continuing assembling; at the time, the five blowing needles are slowly close to the hollow blank, firstly, the hollow blank is punctured by the longest central blowing needle so as to blow air, and secondly, the hollow blank is punctured by the corner blowing needles with the same length at four corners so as to blow air, so that simultaneous blowing from five side surfaces is realized, and the tray blank is uniformly and closely adhered to the surface of a die cavity instantly. Finally, the method for producing the plastic tray, which has the advantages of uniformity in wall thickness, high intensity, low raw material consumption, low cost, stable quality and high efficiency, is provided.

Owner:吴忠市恒通塑料制品有限公司

High-toughness polyester resin and its synthesis method

ActiveCN111748083BHigh heat distortion temperatureHigh elongation at breakHeat deflection temperaturePolymer science

The invention belongs to the technical field of polymer polyester materials, and in particular relates to a high-toughness polyester resin and a synthesis method thereof. In terms of mass percentage, the raw material composition consists of 20%-40% of glycol, 30%-50% of dibasic acid and / or acid anhydride, 20%-40% of dilute solvent and 0.01%-0.1% of auxiliary agent. The high-toughness polyester resin described in the present invention has low viscosity and high reactivity, strong bonding performance, high heat distortion temperature and elongation at break, and high strength of the resin cast body; it is used for making artificial marble chips Material bonding and artificial quartz stone plates, etc., have good wettability with fillers, good toughness, and excellent mechanical strength.

Owner:山东凯威尔新材料有限公司

A finishing agent for improving leather resistance to low-temperature drying environment

InactiveCN107384081BImprove uniformityGood storage stabilityCellulose derivative coatingsGlycidyl methacrylateAcrylic resin

The invention specifically relates to a finishing agent for improving the resistance of leather to a low-temperature dry environment, belonging to the technical field of leather finishing. The finishing agent comprises the following raw materials: acrylic resin, hydroxyethylmethyl cellulose, thionyl chloride, an organometallic compound, a fatty amine curing agent, nano-silica, glycidyl methacrylate, isophorone diisocyanate and methyl acrylate. Compared with the prior art, the finishing g agent has the advantages that the finishing agent can effectively prevent cracks under cold and dry conditions; and after a dermal surface is uniformly coated by a film formed by the finishing agent, surface performance of a dermal material is improved while good air permeability of the dermal material is guaranteed.

Owner:安徽乐踏鞋业有限公司

a cable material

ActiveCN111117136BImprove thermal stabilityStrong UV resistanceSilicon organic compoundsPlastic/resin/waxes insulatorsPolymer sciencePtru catalyst

Owner:WENZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com