Cold stamping solid pharmaceutical composite hard tablet

A composite hard sheet and cold stamping technology, applied in the field of pharmaceutical packaging materials, can solve the problems of large loss of rolling equipment, unsuitable for high-speed stamping, and limited use range, so as to improve rolling stability and improve the quality of production technology. The effect of improving the grade and overall molding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

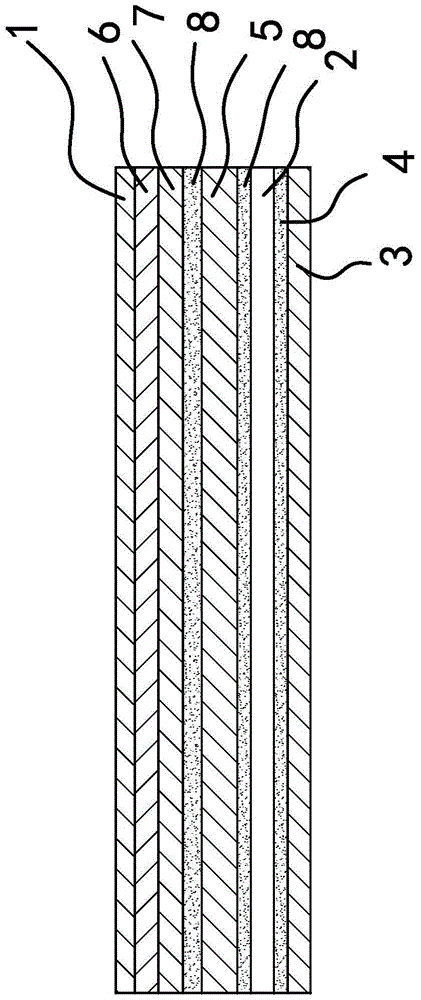

[0033] A cold-stamped solid pharmaceutical composite hard sheet includes a polyamide layer 1, an aluminum foil layer 2, and a polyvinyl chloride layer 3 arranged in sequence, and a dry compound glue layer 4 is arranged between the aluminum foil layer 2 and the polyvinyl chloride layer 3, The surface of the aluminum foil layer 2 includes an aluminum phosphate film and a rough layer, and the surface of the aluminum foil layer 2 is coated with a polyurethane resin layer 5 and the polyurethane resin layer 5 is located between the aluminum foil layer 2 and the polyamide layer 1, and the polyamide layer 1 and the aluminum foil layer 2 are further provided with a maleic anhydride modified polyethylene layer 6 and an acrylic modified polyethylene layer 7 in sequence, the acrylic modified polyethylene layer 7 and the polyurethane resin layer 5, the aluminum foil layer 2 and the polyurethane resin An adhesive layer 8 is arranged between the layers 5, and the density of the dry compound g...

Embodiment 2

[0040] A cold-stamped solid pharmaceutical composite hard sheet includes a polyamide layer 1, an aluminum foil layer 2, and a polyvinyl chloride layer 3 arranged in sequence, and a dry compound glue layer 4 is arranged between the aluminum foil layer 2 and the polyvinyl chloride layer 3, The surface of the aluminum foil layer 2 includes an aluminum phosphate film and a rough layer, and the surface of the aluminum foil layer 2 is coated with a polyurethane resin layer 5 and the polyurethane resin layer 5 is located between the aluminum foil layer 2 and the polyamide layer 1, and the polyamide layer 1 and the aluminum foil layer 2 are further provided with a maleic anhydride modified polyethylene layer 6 and an acrylic modified polyethylene layer 7 in sequence, the acrylic modified polyethylene layer 7 and the polyurethane resin layer 5, the aluminum foil layer 2 and the polyurethane resin An adhesive layer 8 is arranged between the layers 5, and the density of the dry compound g...

Embodiment 3

[0047] A cold-stamped solid pharmaceutical composite hard sheet includes a polyamide layer 1, an aluminum foil layer 2, and a polyvinyl chloride layer 3 arranged in sequence, and a dry compound glue layer 4 is arranged between the aluminum foil layer 2 and the polyvinyl chloride layer 3, The surface of the aluminum foil layer 2 includes an aluminum phosphate film and a rough layer, and the surface of the aluminum foil layer 2 is coated with a polyurethane resin layer 5 and the polyurethane resin layer 5 is located between the aluminum foil layer 2 and the polyamide layer 1, and the polyamide layer 1 and the aluminum foil layer 2 are further provided with a maleic anhydride modified polyethylene layer 6 and an acrylic modified polyethylene layer 7 in sequence, the acrylic modified polyethylene layer 7 and the polyurethane resin layer 5, the aluminum foil layer 2 and the polyurethane resin An adhesive layer 8 is arranged between the layers 5, and the density of the dry compound g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com