A kind of light curing polyurethane coating and its preparation method and application

A polyurethane coating and light-curing technology, applied in polyurea/polyurethane coatings, anti-corrosion coatings, fire-resistant coatings, etc., can solve the problems of low strength and many pores in the film, and achieve the effect of strong heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

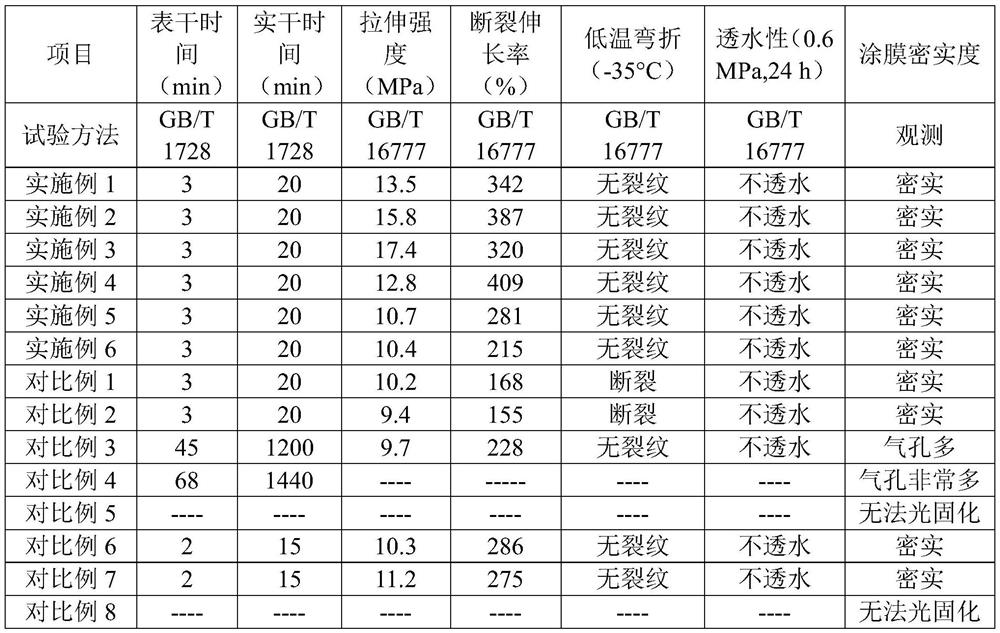

Examples

Embodiment 1

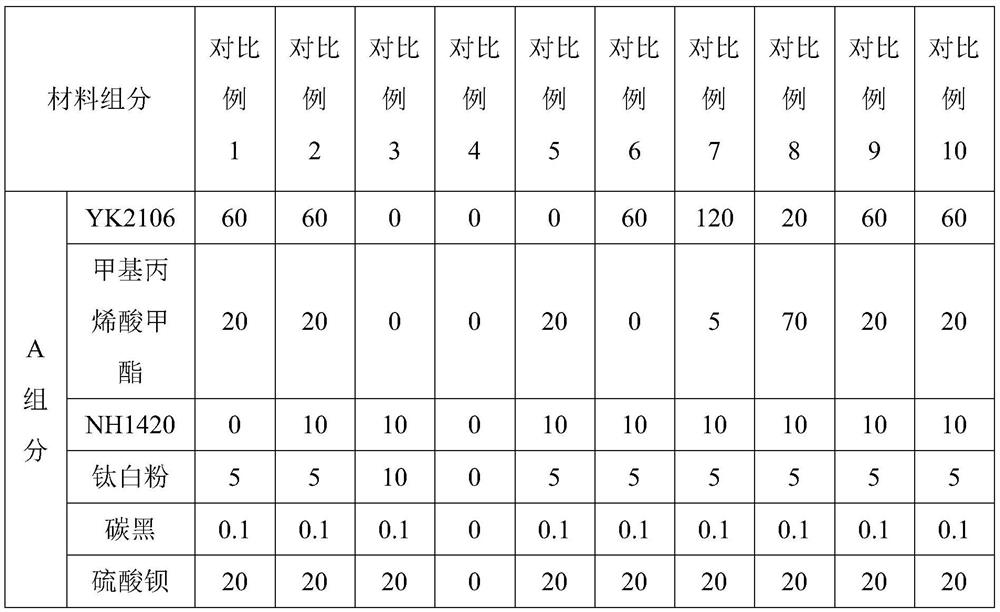

[0085] A photocurable polyurethane coating composed of the following raw material components:

[0086] The A component includes: polyurethane acrylate (Yantai Houde Polymer Material Co., Ltd., YK2106), 20 methacrylate, polymetanpartate (Bayer Polymer Co., Ltd. NH1420) 10 copies of pigments (10 pieces of titanium white powder (golden red, brand CR8282) and 0.1 parts of color-carbon carbon (6000 mesh);

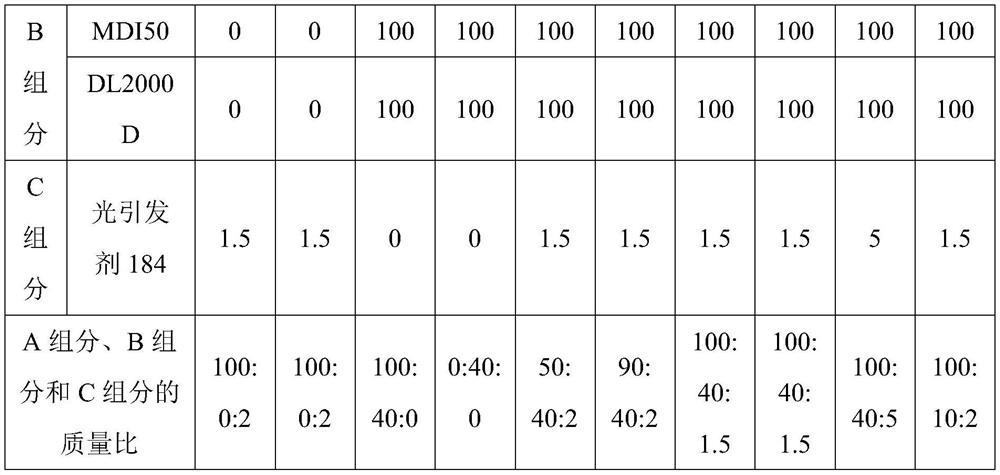

[0087] B components include parts by weight, including: liquefied diphenylmethane diisocyanate (Wanhua Chemistry) MDI-50) 100 parts of 100 parts and polycyclopropane ether diol (Shandong Lanxing East China Co., Ltd., DL2000D);

[0088] The C component is photoinitiator 184, and the chemical component is 1-hydroxycyclohexylphenylmethyl;

[0089] The mass ratio of the A component, the B component, and the C component is 100: 1.5.

[0090] The preparation method of the photocurable urethane coating includes the steps of:

[0091] (1) 60 parts of polyurethane acrylate were stirred at ...

Embodiment 2

[0095] In the same embodiment, the difference is that the b component is subjected to 40 parts by weight of the partial part of the diisocyanate 40 parts and 40 parts of the polycyclopropane ether diol, the A component, B component and C group. The mass ratio of points is 100: 80: 1.5, the other components and the preparation method are constant.

Embodiment 3

[0097] In the same embodiment, the difference is that the component B components comprise: 40 parts of the liquefied diphenylmethane diisocyanate and 40 parts of polycyclopropane ether glycol, the A component, B component and C group The mass ratio of the division is 100: 100: 1.5, the other components content and the preparation method are constant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| amine value | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com