Composite sole hot melt adhesive film and preparation method thereof

A hot-melt adhesive film and composite sole technology, applied in the field of footwear materials, can solve problems such as insufficient performance of sole bonding materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

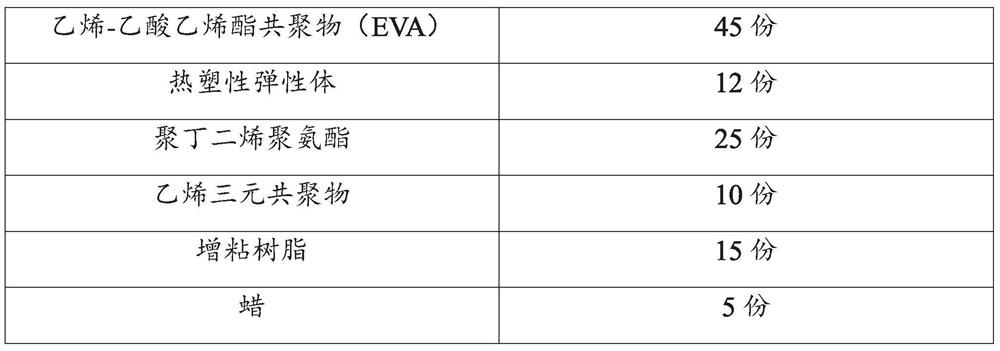

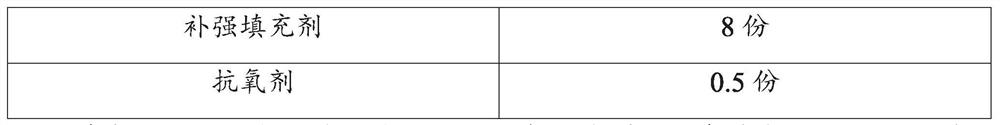

[0048] A kind of hot-melt adhesive film for composite shoe sole, described hot-melt adhesive film is prepared by the following raw materials by weight:

[0049]

[0050]

[0051] Wherein the VA content in the ethylene-vinyl acetate copolymer (EVA) is 5%, the thermoplastic elastomer is JSR RB820, and the ethylene terpolymer is ethylene-methyl acrylate-methacrylic acid shrink Glyceride terpolymer, the tackifying resin is prepared from rosin glyceride and rosin pentaerythritol ester in a ratio of 1:1, the wax is polyethylene wax, and the reinforcing filler is gas-phase white Carbon black, described antioxidant is antioxidant 1010;

[0052] A kind of preparation method of hot-melt adhesive film for composite shoe sole, it comprises the following steps:

[0053] The first step: add the material in the formula amount into a high-speed mixer for pre-mixing to obtain a molten material, wherein the melting temperature is 110°C, the stirring speed is 500r / min, and the stirring ti...

Embodiment 2

[0057] A kind of hot-melt adhesive film for composite shoe sole, described hot-melt adhesive film is prepared by the following raw materials by weight:

[0058] Ethylene-vinyl acetate copolymer (EVA) 50 copies thermoplastic elastomer 15 copies Polybutadiene polyurethane 20 copies Ethylene terpolymer 8 servings tackifying resin 12 copies wax 3 copies Reinforcing filler 6 servings antioxidant 0.6 parts

[0059] The VA content in the ethylene-vinyl acetate copolymer (EVA) is 8%, the thermoplastic elastomer is JSR RB830, and the ethylene terpolymer is ethylene-glycidyl methacrylate-acrylic acid Methyl ester terpolymer, the tackifying resin is a mixture of C5 petroleum resin and C9 petroleum resin in a mass ratio of 1:1, the wax is semi-refined paraffin wax, and the reinforcing filler Agent is fumed white carbon black, and described antioxidant is antioxidant BHT;

[0060] A kind of preparation method of hot-melt adh...

Embodiment 3

[0065] A kind of hot-melt adhesive film for composite shoe sole, described hot-melt adhesive film is prepared by the following raw materials by weight:

[0066] Ethylene-vinyl acetate copolymer (EVA) 45 copies thermoplastic elastomer 10 copies Polybutadiene polyurethane 25 copies Ethylene terpolymer 10 copies tackifying resin 10 copies wax 5 copies Reinforcing filler 5 copies antioxidant 0.5 parts

[0067] The VA content in the ethylene-vinyl acetate copolymer (EVA) is 10%, the thermoplastic elastomer is JSR RB820 and JSR RB830 mixed at a mass ratio of 1:1, and the ethylene ternary The copolymer is an ethylene-glycidyl methacrylate-methyl acrylate terpolymer, and the tackifying resin is a mixture of C5 petroleum resin and C9 petroleum resin in a mass ratio of 1:2. The wax is polytetrafluoroethylene wax, the reinforcing filler is fumed silica, and the antioxidant is antioxidant 246;

[0068] A kind of preparation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com