Preparation method of gum for wall

A wall and adhesive technology, applied in the direction of adhesives, film/sheet adhesives, adhesive types, etc., can solve the problems that restrict the development and application of adhesives for walls, weak bonding strength, and waste of materials. and other problems, to achieve the effect of high elongation at break, high peel strength and high adhesive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

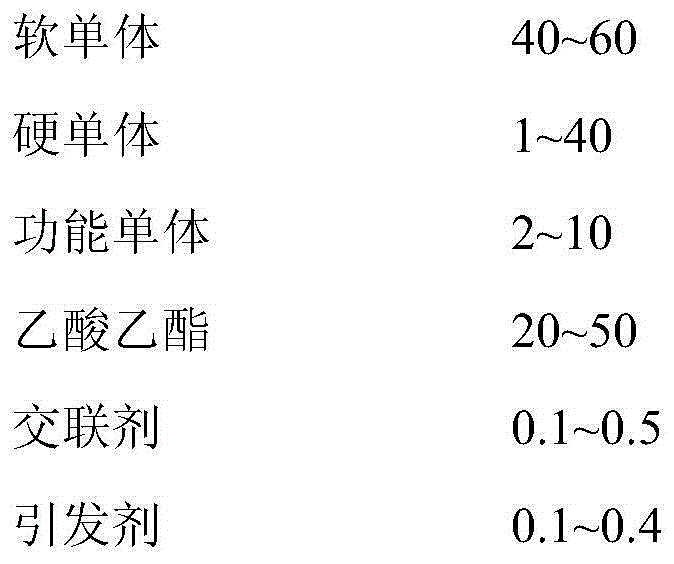

Method used

Image

Examples

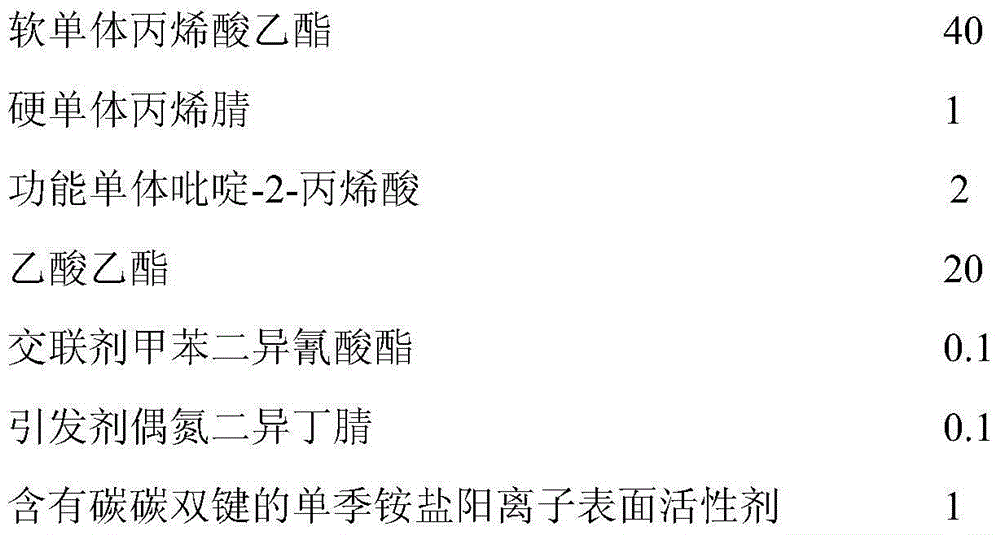

Embodiment 1

[0026] A method for preparing a back adhesive for walls, comprising coating an ink-absorbing coating with a thickness of 20mm on coated paper and coating an acrylate pressure-sensitive adhesive layer on a release layer, and drying it through a dry compounding process The back glue for the wall is compounded, and the coating and drying process is to coat the base material with the acrylate pressure-sensitive adhesive for the wall, and then dry it through the box oven type drying and heating equipment. The entrance of the oven type drying equipment is It is divided into 8 drying areas to the exit; the amount of coating is 60g / m 2 ; The temperature range and air volume range of the drying process are controlled at: 30°C, and the air volume is 1m / s; The monomer and the functional monomer are copolymerized, the functional monomer contains at least pyridine-2-acrylic acid, and the preparation method of the acrylate pressure-sensitive adhesive for the wall is as follows;

[0027] In...

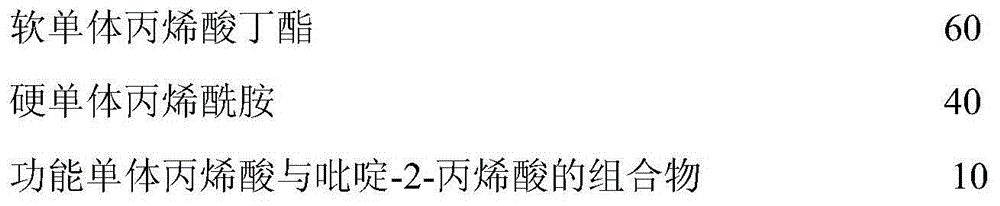

Embodiment 2

[0032] A preparation method for back adhesive for walls, comprising coating an ink-absorbing coating with a thickness of 100mm on double-adhesive paper and coating an acrylic pressure-sensitive adhesive layer on a release layer, and drying and laminating The back glue for the wall is obtained by compounding the process. The coating and drying process is to coat the base material with the acrylic pressure-sensitive adhesive for the wall, and then dry it through the box oven type drying and heating equipment. The oven type drying equipment The entrance to the exit is divided into 8 drying areas; the amount of coating is 80g / m 2 The temperature range and air volume range of the drying process are controlled at: 130°C, and the air volume is 30m / s; It is formed by copolymerization of a functional monomer and a functional monomer, and the functional monomer contains at least pyridine-2-acrylic acid. The preparation method of the acrylate pressure-sensitive adhesive for the wall is a...

Embodiment 3

[0040] A method for preparing a back adhesive for walls, comprising coating an ink-absorbing coating with a thickness of 30 mm on synthetic paper and coating an acrylate pressure-sensitive adhesive layer on a release layer, and drying it through a dry compounding process The back glue for the wall is compounded, and the coating and drying process is to coat the base material with the acrylate pressure-sensitive adhesive for the wall, and then dry it through the box oven type drying and heating equipment. The entrance of the oven type drying equipment is It is divided into 8 drying areas at the exit; the amount of coating is 70g / m 2 ; The temperature range and air volume range of the drying process are controlled at: 50°C, and the air volume is 5m / s; It is formed by copolymerization of a functional monomer and a functional monomer, and the functional monomer contains at least pyridine-2-acrylic acid. The preparation method of the acrylate pressure-sensitive adhesive for the wal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com