Water-emulsion organic silicon composited acrylic acid modified asphalt cement-base waterproof coating and preparation method thereof

A technology of modified asphalt and waterproof coating, applied in the field of cement-based waterproof coating and its preparation, can solve the problems of adverse effect of construction period, difficult construction of waterproof engineering, and high degree of drying of foundation, achieve excellent shear resistance and avoid demulsification. , the effect of large elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

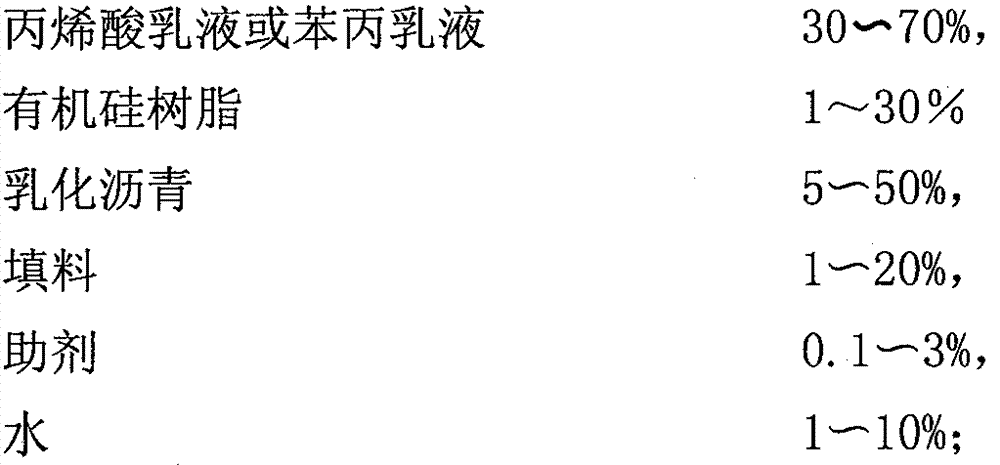

Method used

Image

Examples

Embodiment 1

[0046] Water-emulsion type organic silicon composite acrylic modified asphalt cement-based waterproof coating, which is composed of component A and component B, the weight ratio of component A: component B is 1:0.8;

[0047] Each raw material in the first component and the weight percentage of the first component are:

[0048] Styrene acrylic emulsion (R106 emulsion of Union Carbide Company) 70.0%,

[0049] Silicone polymer emulsion (isobutyl trimethoxysilane emulsion) 3%

[0050] Emulsified asphalt (commercially available, anionic emulsified asphalt) 15.0%,

[0051] Filler (fly ash and mica powder, each accounting for 1 / 2 by weight) 8.0%,

[0052] Additives (sodium pentachlorophenate and BYK-22 defoamer, weight each 1 / 2) 0.8%,

[0053] Water (tap water) 3.2%,

[0054] The raw materials in the second component and their weight percentages are:

[0055] Cement (white cement) 95.0%,

[0056] Filler (calcium carbonate) 5.0%.

[0057] The preparation method of the above-mentioned water-emulsion s...

Embodiment 2

[0065] Water-emulsion silicone composite acrylic modified asphalt cement-based waterproof coating, which is composed of component A and component B, and the weight ratio of component A: component B is 1:1.25;

[0066] Each raw material in the first component and the weight percentage of the first component are:

[0067] Acrylic emulsion (F-400 emulsion of BASF) 50.0%,

[0068] Silicone polymer emulsion (vinyl benzyl dimethoxy silane emulsion) 5%

[0069] Emulsified rubber modified asphalt (commercially available, anionic) 25.0%,

[0070] Filler (fly ash) 12.0%,

[0071] Additives (BYK-33 defoaming agent and T-731 wetting and dispersing agent, each accounting for 1 / 2 by weight) 0.6%,

[0072] Water (tap water) 7.4%,

[0073] The raw materials in the second component and their weight percentages are:

[0074] Cement (Ordinary Portland Cement) 100.0%.

[0075] The preparation method of the above-mentioned water-emulsion silicone composite acrylic modified asphalt cement-based waterproof coating...

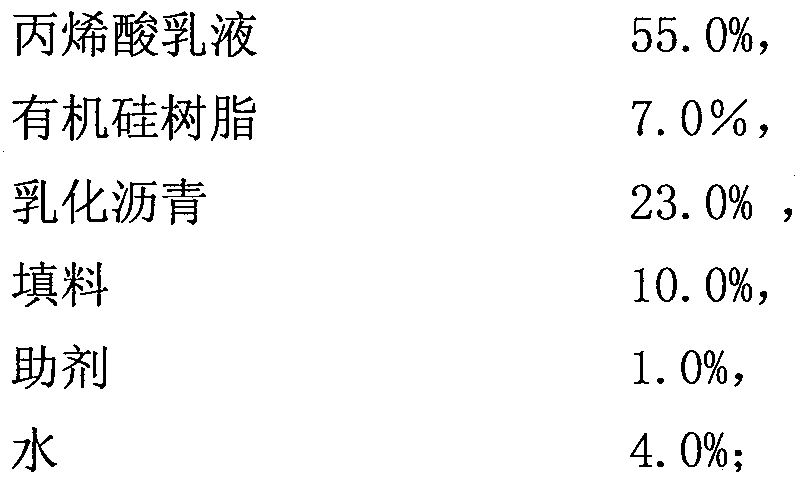

Embodiment 3

[0083] Water-emulsion silicone composite acrylic modified asphalt cement-based waterproof coating, which is composed of component A and component B, and the weight ratio of component A: component B is 1:1.2;

[0084] The raw materials in the first component and their weight percentages are:

[0085] Styrene acrylic emulsion (R106 emulsion) 32.0%,

[0086] Silicone polymer emulsion (Dimethyldimethoxysilane emulsion) 30%

[0087] Emulsified asphalt (anionic emulsified asphalt and emulsified rubber modified asphalt, each accounting for 1 / 2 by weight) 33.0%,

[0088] Filler (mica powder and kaolin) 1.0%,

[0089] Additives (082 defoamer, BYK-181 wetting and dispersing agent and sodium pentachlorophenate, 1 / 3 by weight each) 2.5%,

[0090] Water (tap water) 1.5%,

[0091] The raw materials in the second component and their weight percentages are:

[0092] Cement (white cement) 70.0%,

[0093] Filler (calcium carbonate and quartz powder, each accounting for 1 / 2 by weight) 30.0%.

[0094] The prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com