High-flexibility geomembrane and preparation method for same

A geomembrane, high flexibility technology, applied in the direction of chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the problem of easily damaged geomembrane fixing facilities, affecting construction and construction quality, and large coefficient of thermal expansion and contraction and other problems, to achieve good chemical stability, high unidirectional and multi-extension performance, and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

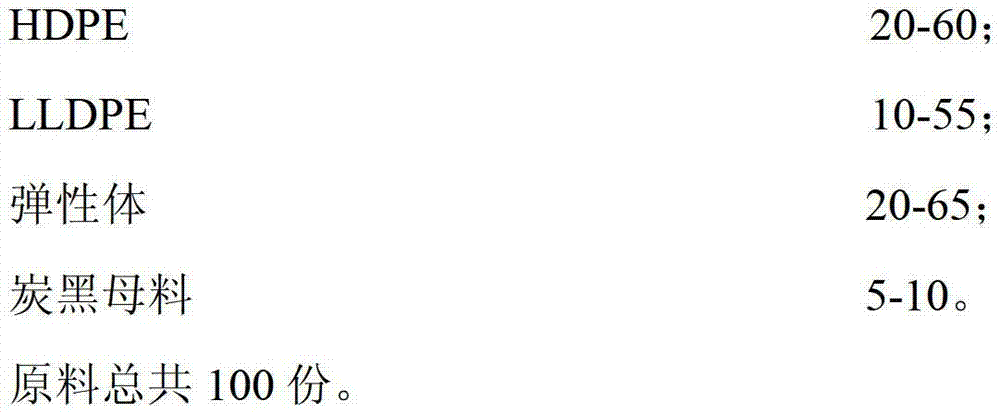

[0024] High flexible geomembrane of the present invention, raw material and weight percentage thereof are:

[0025]

[0026] Among them, the HDPE butene molar ratio is 1.8%, the weight average molecular weight is 230,000, the molecular weight distribution is 18, and the relative branching degree is 0.20; the LLDPE butene molar ratio is 2.1%, the weight average molecular weight is 110,000, the molecular weight distribution is 3, and the relative branching degree is 2.1%. Degree 1.0.

[0027] The preparation method of highly flexible geomembrane of the present invention is as follows:

[0028] Weigh the above raw materials according to the formula, and mix them in the mixer for 30 minutes at room temperature. The fully mixed raw materials are sent to the feed port of the extruder through the suction machine. The temperature of the screw barrel is 180°C. After melting and mixing uniformly in the extruder, it enters the three-layer co-extrusion die head with a temperature of 2...

Embodiment 2

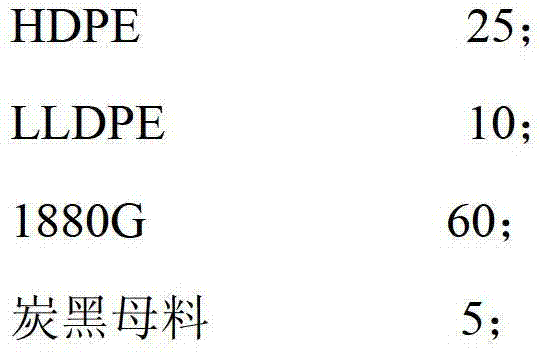

[0034] High flexible geomembrane of the present invention, raw material and weight percentage thereof are:

[0035]

[0036] Among them, the HDPE butene molar ratio is 2.5%, the weight average molecular weight is 280,000, the molecular weight distribution is 21, and the relative branching degree is 0.24; the LLDPE butene molar ratio is 2.7%, the weight average molecular weight is 110,000, the molecular weight distribution is 4, and the relative branching degree is 2.7%. Degree 1.4.

[0037] The preparation method of highly flexible geomembrane of the present invention is as follows:

[0038] The above raw materials are weighed according to the formula, and mixed in a mixer at room temperature for 40 minutes. The fully mixed raw materials are sent to the feed port of the extruder through the suction machine. The screw speed of the extruder is 20 min / rev. The temperature of the section screw barrel is 140°C. After melting and mixing uniformly in the extruder, it enters the t...

Embodiment 3

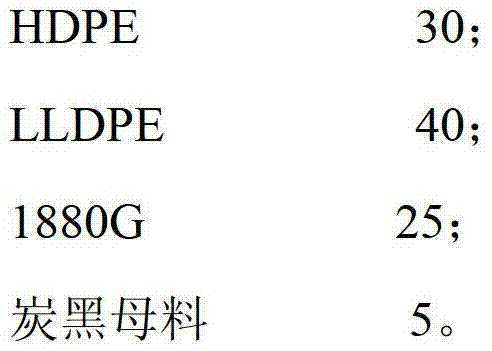

[0044] High flexible geomembrane of the present invention, raw material and weight percentage thereof are:

[0045]

[0046] Among them, the molar ratio of HDPE butene is 3%, the weight average molecular weight is 300,000, the molecular weight distribution is 23, and the relative branching degree is 0.3; the LLDPE butene molar ratio is 3%, the weight average molecular weight is 150,000, the molecular weight distribution is 5, and the relative branching degree is 5%. Degree 1.8.

[0047] The preparation method of highly flexible geomembrane of the present invention is as follows:

[0048] The above raw materials are weighed according to the formula, and mixed in a mixer at room temperature for 20 minutes, and the fully mixed raw materials are sent to the feed port of the extruder through a suction machine, and the screw speed of the extruder is 30 min / rev. The temperature of the section screw barrel is 220°C. After melting and mixing uniformly in the extruder, it enters the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at yield | aaaaa | aaaaa |

| elongation at yield | aaaaa | aaaaa |

| elongation at yield | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com