Cold stamping formed composite hard sheet for packaging medicines

A composite hard sheet and packaging technology, applied in the field of pharmaceutical packaging, can solve the problems of separation layer, high production cost of composite hard sheet, aluminum cracking, etc., achieve high peel strength, cost advantage, prevent aluminum cracking and separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

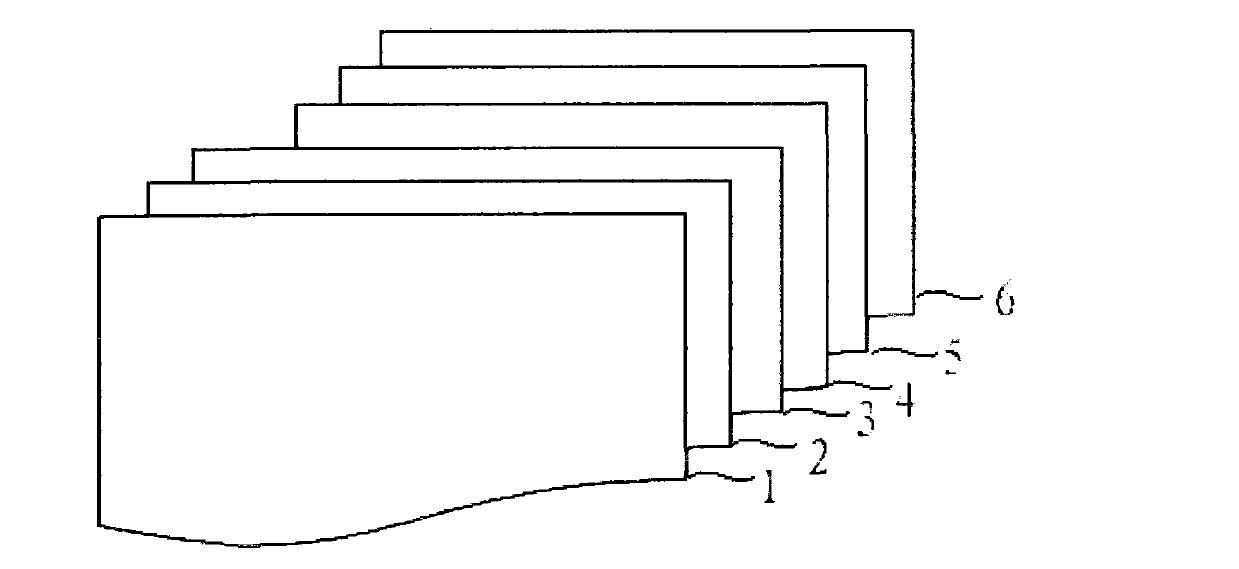

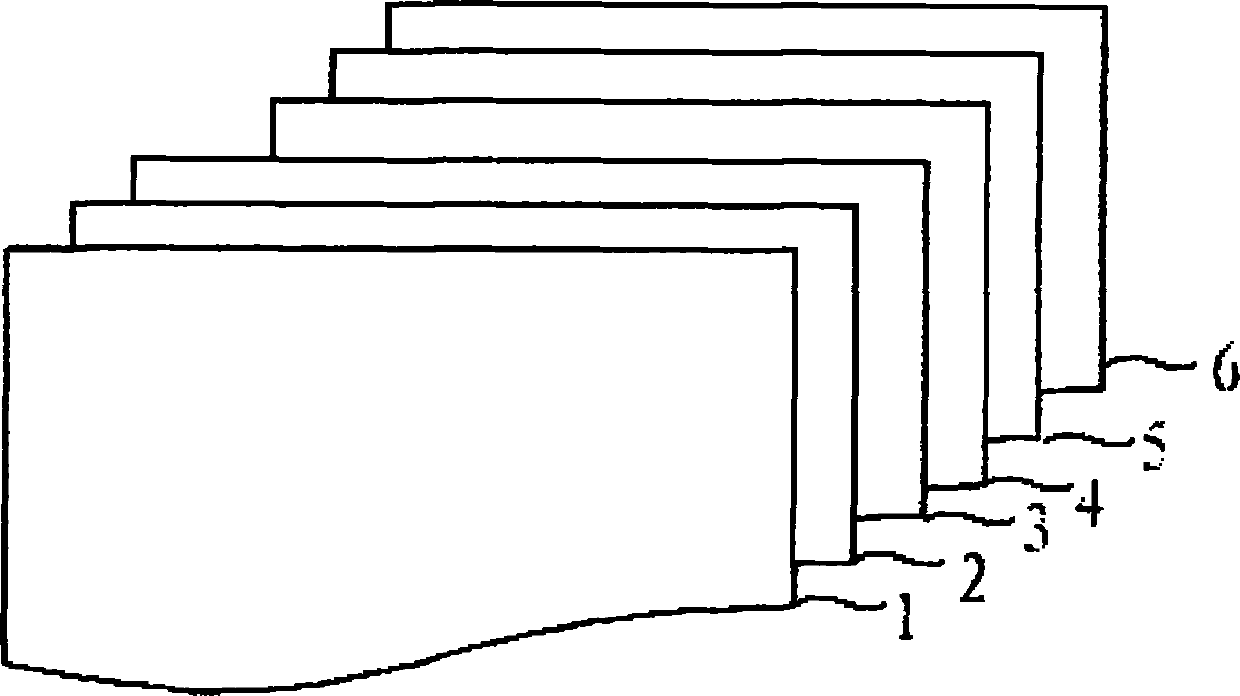

[0012] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0013] see figure 1 As shown, a composite hard sheet for cold stamping molding for pharmaceutical packaging, including a polyamide layer 1, an aluminum foil layer 4, and a polyvinyl chloride layer 6 arranged in sequence, between the aluminum foil layer 4 and the polyvinyl chloride layer 6 A dry compound glue layer 5 is arranged, and a maleic anhydride modified polyethylene layer 2 and an acrylic acid modified polyethylene layer 3 are arranged between the polyamide layer 1 and the aluminum foil layer 4 .

[0014] The method for preparing a composite hard sheet for cold stamping molding for pharmaceutical packaging of the present invention comprises the following steps: co-extruding the modified polyethylene particles of the maleic anhydride-modified polyethylene layer 2 and the acrylic acid-modified polyethylene layer 3 Compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com