Double-phase high-strength high-plasticity titanium alloy with layered structure and preparation method of double-phase high-strength high-plasticity titanium alloy

A layered structure, titanium alloy technology, applied in the field of metal materials, can solve problems such as changing the stability of the β matrix, hindering the development of metastable β titanium alloys, and the yield strength of TRIP titanium alloys has not achieved practical breakthroughs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] A method for preparing a two-phase high-strength and high-plasticity TRIP titanium alloy with a layered structure, comprising the following steps:

[0037] Step 1. Heat the titanium alloy in the β single-phase region at 1000-1100°C in a muffle furnace for 1-2 hours, and then quench it to room temperature to obtain a uniform β-phase;

[0038] Step 2, the alloy obtained in step 1 is heated up to a temperature above the transformation point again, and rolled after being kept warm for 10-20min.

[0039] The temperature of the phase transition point is 765±5°C, the heating temperature is from the phase transition point temperature to 10°C above the phase transition point temperature, and the heating temperature is 770-780°C.

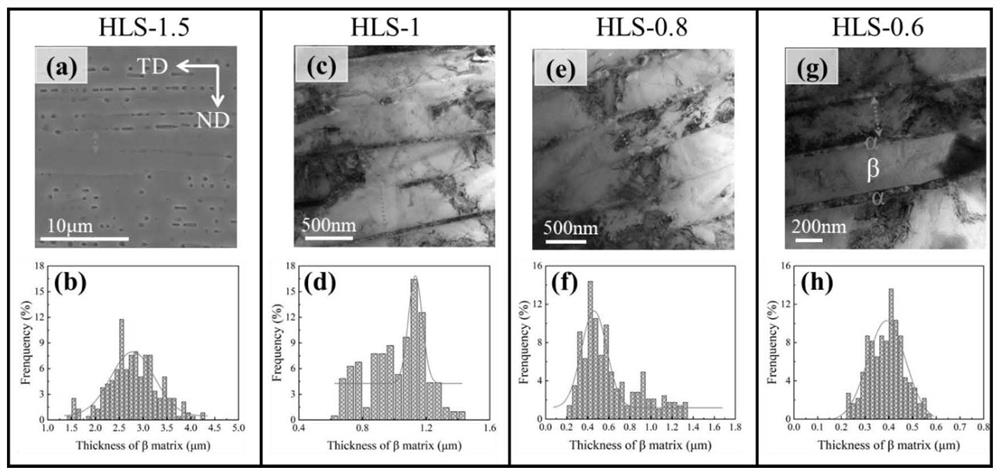

[0040] Step 3. The titanium alloy obtained in step 2 is rolled across β, and the rolling reduction in a single pass is 3 to 5% of the rolling deformation. After each 1 to 2 passes of rolling, the temperature is lower than the phase transition point tem...

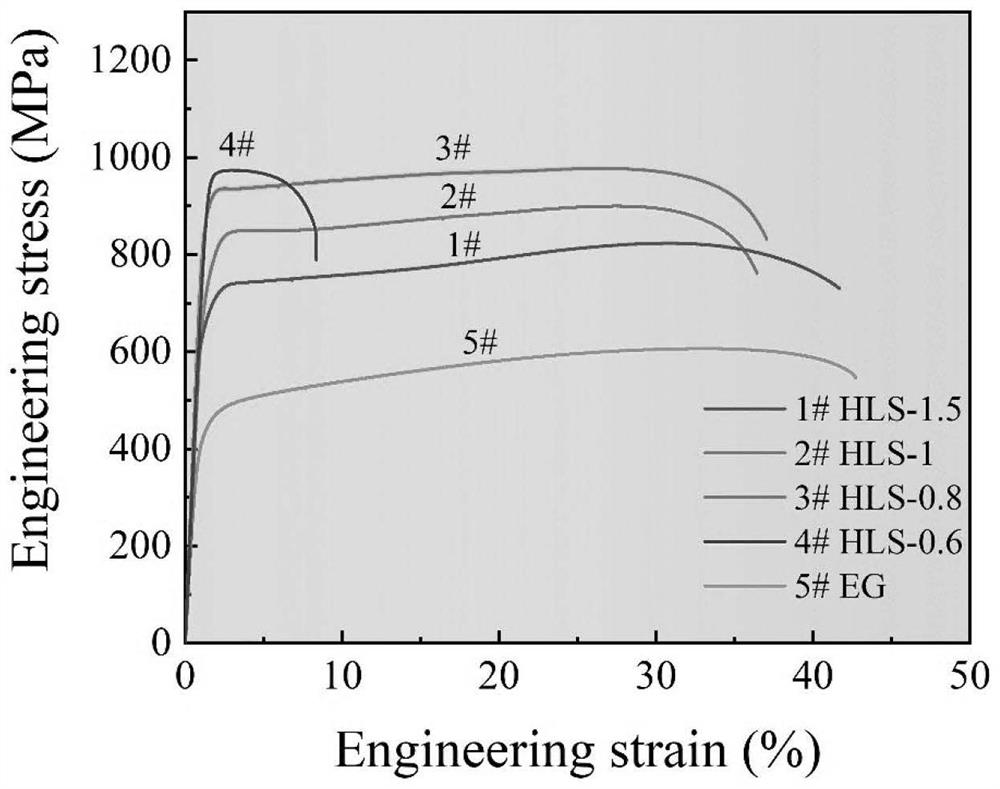

Embodiment 1

[0053] A method for preparing a two-phase high-strength and high-plasticity TRIP titanium alloy with a layered structure, comprising the following steps:

[0054] Step 1. Heat the 10mm thick Ti-Al-Mo-Cr-Zr metastable β-titanium alloy plate in a muffle furnace at 1000°C for 60 minutes, and then quench it to room temperature;

[0055] The composition of Ti-Al-Mo-Cr-Zr metastable β titanium alloy is 0.5-1.5% Al, 8-9% Mo, 2.5-4% Cr, 3-4% Zr, and the balance is Ti and Some other unavoidable impurities.

[0056] Step 2, heat the 10mm thick Ti-Al-Mo-Cr-Zr metastable alloy plate at 770°C for 10min in a muffle furnace;

[0057] Step 3. Take it out and roll it. The reduction in a single pass is 3%. After each pass, the sample is returned to the furnace and kept at 770° C. for 1 min. The total rolling reduction is 85%.

[0058] Step 4. Immediately put the rolled sample into a muffle furnace, keep it at 770° C. for 1 min, and then quench it to room temperature to obtain a layered struct...

Embodiment 2

[0061] A method for preparing a layered two-phase high-strength high-plasticity TRIP / TWIP titanium alloy, comprising the following steps:

[0062] Step 1. Heat the 10mm thick Ti-Al-Mo-Cr-Zr metastable β-titanium alloy plate in a muffle furnace at 1000°C for 60 minutes, and then quench it to room temperature;

[0063] The composition of Ti-Al-Mo-Cr-Zr metastable β titanium alloy is 0.5-1.5% Al, 8-9% Mo, 2.5-4% Cr, 3-4% Zr, and the balance is Ti and Some other unavoidable impurities.

[0064] Step 2, keeping the 10mm thick Ti-Al-Mo-Cr-Zr metastable β titanium alloy plate in a muffle furnace at 770°C for 10min;

[0065] Step 3. Take it out and roll it. The reduction in a single pass is 3%. After each pass, the sample is returned to the furnace and kept at 770° C. for 1 min. The total rolling reduction is 90%.

[0066] Step 4. Immediately put the rolled sample into the muffle furnace, hold it at 770°C for 1min, and then quench it to room temperature to obtain a high-strength and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com