a cable material

A cable material, polyethylene technology, applied in circuits, electrical components, plastic/resin/wax insulators, etc., can solve the problems of limiting the application range of cable materials, reducing the tensile strength and elongation at break of polyethylene cable materials, etc. Achieve the effect of large mechanical properties, wide application range, strong tensile strength and elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

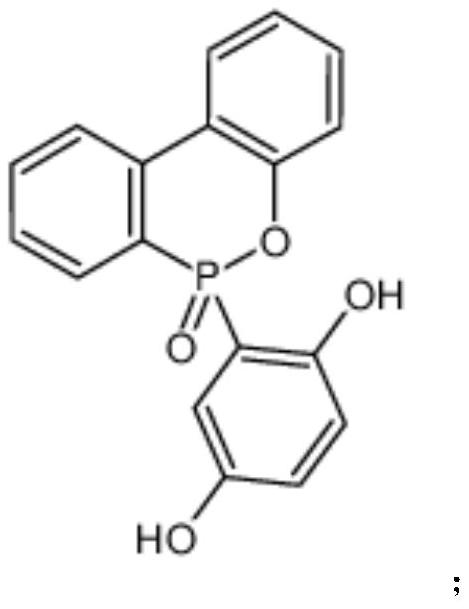

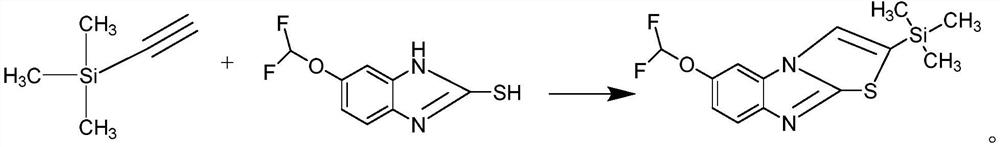

[0052] The preparation method of 6-(difluoromethoxy)-2-(trimethylsilyl)benzo[4,5]imidazo[2,1-b]thiazole comprises the following steps:

[0053] Trimethylethynyl silicon (0.1mol), 5-difluoromethoxy-2-mercapto-1H-benzimidazole (0.13mol), copper fluoride (0.025mol), 2,9-diisopropyl -1,10-Phenanthroline (0.03mol), elemental iodine (0.1mol) and cesium carbonate (0.2mol) were put into a reaction vessel with 200ml of toluene and stirred and mixed; The reaction was carried out for 20 hours to obtain 6-(difluoromethoxy)-2-(trimethylsilyl)benzo[4,5]imidazo[2,1-b]thiazole;

[0054] Its reaction formula is:

[0055]

[0056] Characterization data: 1 H NMR (CDCl 3 ,500MHz,ppm):δ7.54-7.32(m,2H),7.34-7.31(m,1H),7.10-6.89(m,2H),-0.31(s,9H). 13 C NMR (CDCl 3 ,125MHz,ppm):δ167.0,155.9,143.1,141.2,135.8,120.3,119.7,116.6,111.3,100.6,2.5.

[0057] The structural formula of 6-(difluoromethoxy)-2-(trimethylsilyl)benzo[4,5]imidazo[2,1-b]thiazole is

[0058]

Embodiment 2

[0060] The modified polyethylene comprises the following components by weight:

[0061] 60 parts of polyethylene;

[0062] 2 parts of tert-butyl peroxymaleate;

[0063] 3 parts of sodium dodecylbenzenesulfonate;

[0064] 2 parts of dimethylaminopropyl methacryloyl;

[0065] 2 parts of styrene;

[0066] 7 parts of modifier;

[0067] The modifier is vinyltrimethoxysilane, 2,3-bis(2,4,5-trimethyl-3-thiophene) maleic anhydride and (3,3,3-trifluoropropyl) trimethyl A mixture of oxysilanes with a mass ratio of 1:1:1.

[0068] The preparation method of described modified polyethylene comprises the following steps:

[0069] Step 1: Weigh the required materials according to the set weight parts, first mix polyethylene, tert-butyl peroxymaleate, sodium dodecylbenzenesulfonate, dimethylaminopropyl methacryloyl and benzene Add ethylene into the reaction vessel with acetone and stir to mix. After mixing evenly, carry out under the protection of nitrogen at a temperature of 70°C, and...

Embodiment 3

[0072] A cable material, comprising the following components by weight:

[0073] 75 parts of modified polyethylene;

[0074] EPDM rubber 25 points;

[0075] 12 parts of flame retardant;

[0076] 7 parts of plasticizer;

[0077] 3 parts of stabilizer;

[0078] Anti-aging agent 3 parts;

[0079] 1 part lubricant;

[0080] Filling 4 parts.

[0081] Wherein modified polyethylene is made by embodiment 2;

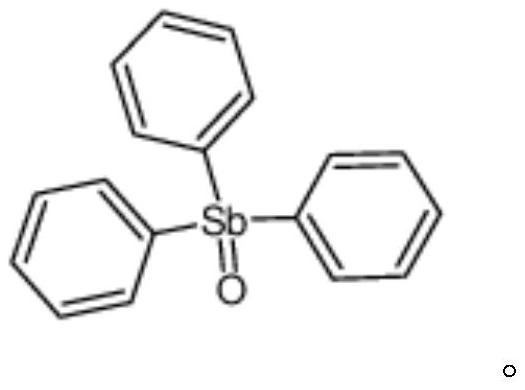

[0082] The flame retardant is 6-(difluoromethoxy)-2-(trimethylsilyl)benzo[4,5]imidazo[2,1-b]thiazole, 10-(2,5 -dihydroxyphenyl)-10-hydrogen-9-oxa-10-phosphaphenanthrene-10-oxide and a mixture of triphenyl antimony oxide, the mass ratio of which is 2:3:1; where 6-(two Fluoromethoxy)-2-(trimethylsilyl)benzo[4,5]imidazo[2,1-b]thiazole was prepared from Example 1;

[0083] The stabilizer is bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate, 1,2-epoxy-4-vinylcyclohexane and tributylvinyltin mixture with a mass ratio of 2:1:1.

[0084] The anti-aging agent is (R)-N-epoxypropyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com