Decortication system and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

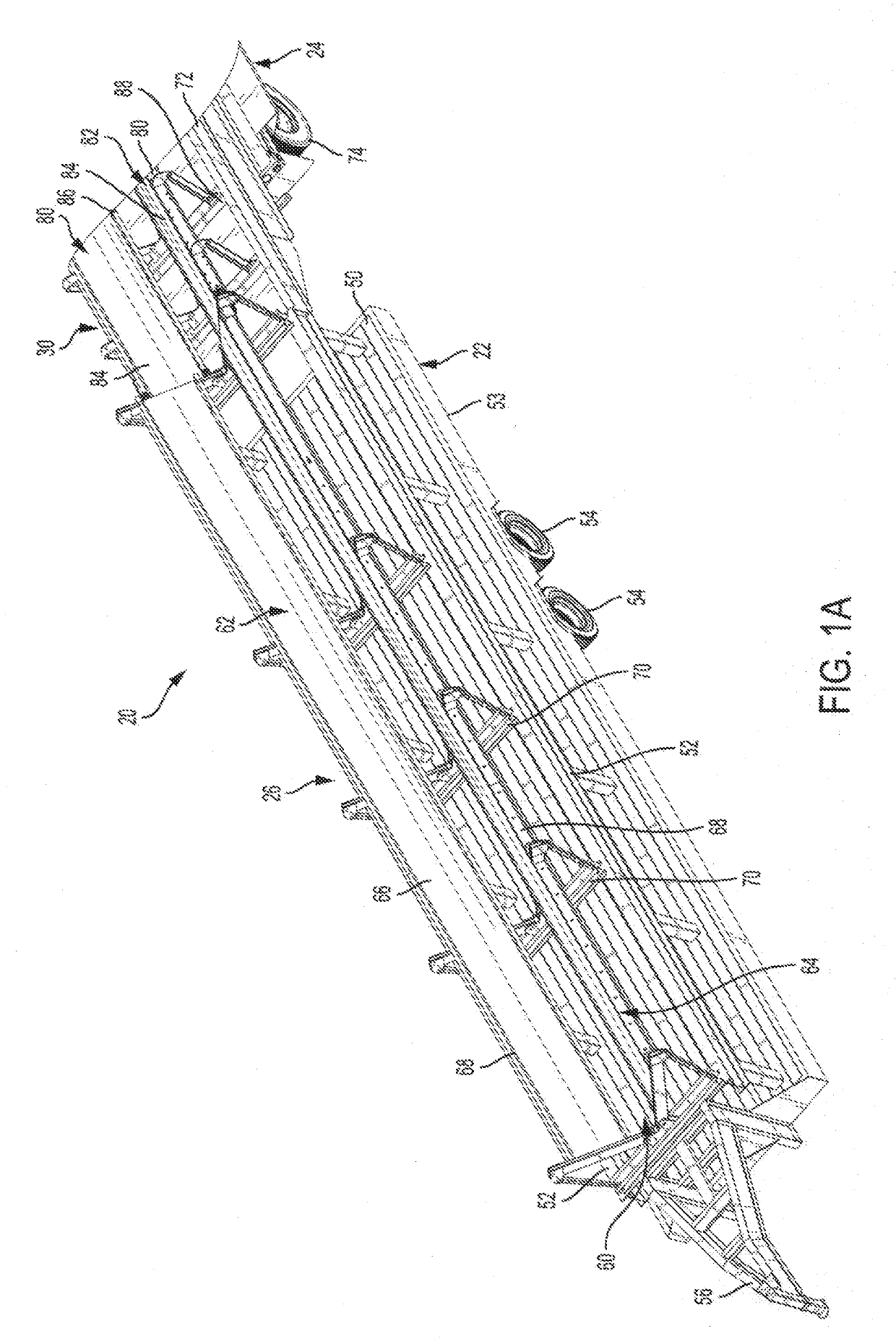

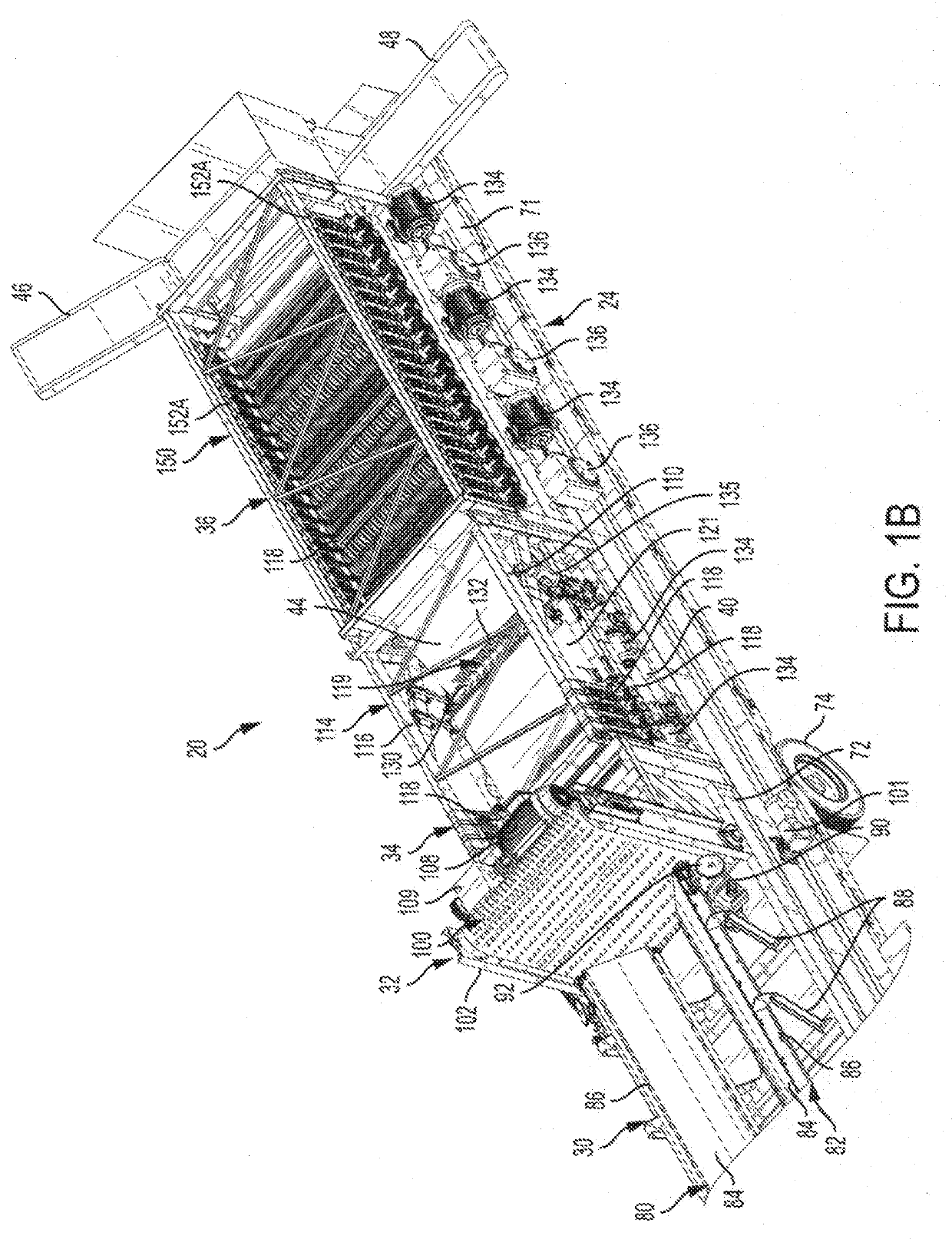

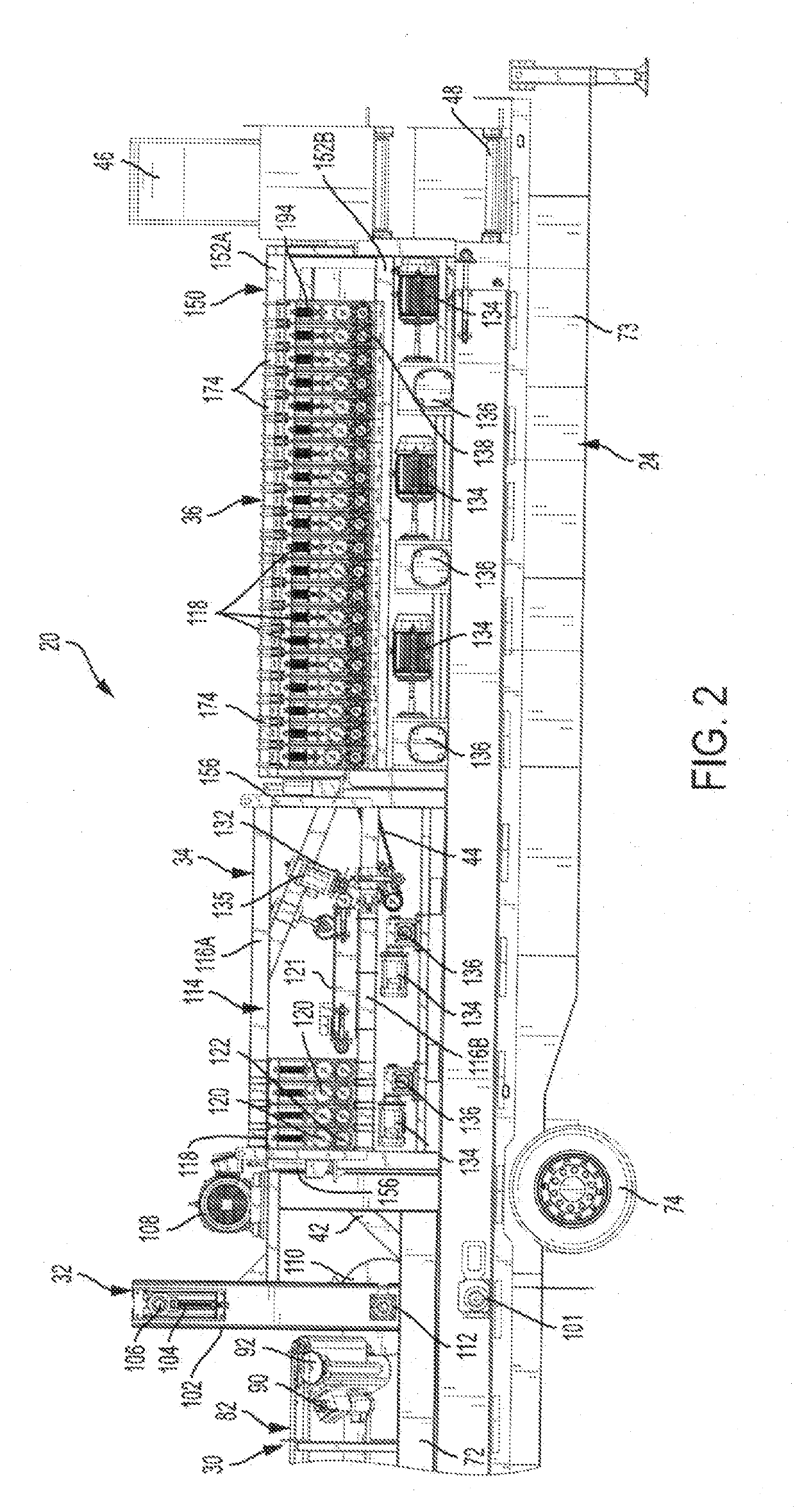

[0045]Decorticating systems configured as described herein could be used to decorticate stalks of a wide variety of organic crop plants, including, but not limited to, ramie, flax, hemp, kenaf, and jute. The exemplary decorticating system illustrated in the figures and discussed below has several advantages, including.[0046]It is fully automated.[0047]It can handle unoriented stalks delivered to the machine in bulk masses such as large bales.[0048]It has a high capacity in excess of 5 tons per hour.[0049]It is extremely effective.[0050]It is mobile.[0051]It is versatile and modular.

[0052]Referring now to the drawings and initially to FIGS. 1A and 1B, a decorticating system or simply “decorticator” or “system”20 constructed in accordance with an embodiment of the invention is illustrated. The system 20 is mounted on two trailers 22 and 24 arranged end-to-end and thus is fully mobile. Each trailer 22, 24 may be on the order of 40 feet to 55 feet long. Each trailer 22 or 24 may be expa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mass | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Mass flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com