Tree bast fiber and method for processing tree bast

a technology of tree bast and bast fiber, which is applied in the field of textile fiber, can solve the problems of inability to provide a large amount of cheap mulberry bark for producing fiber, and achieve the effects of wide application in the textile industry, similar performance, and cheap pri

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

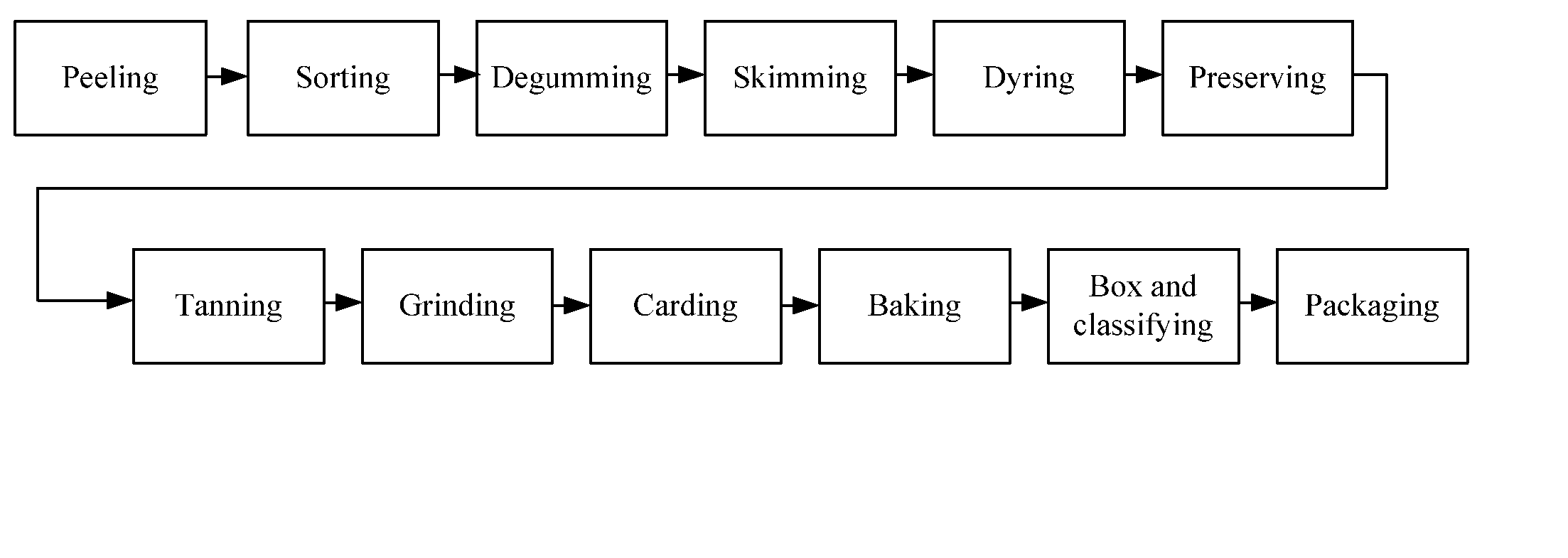

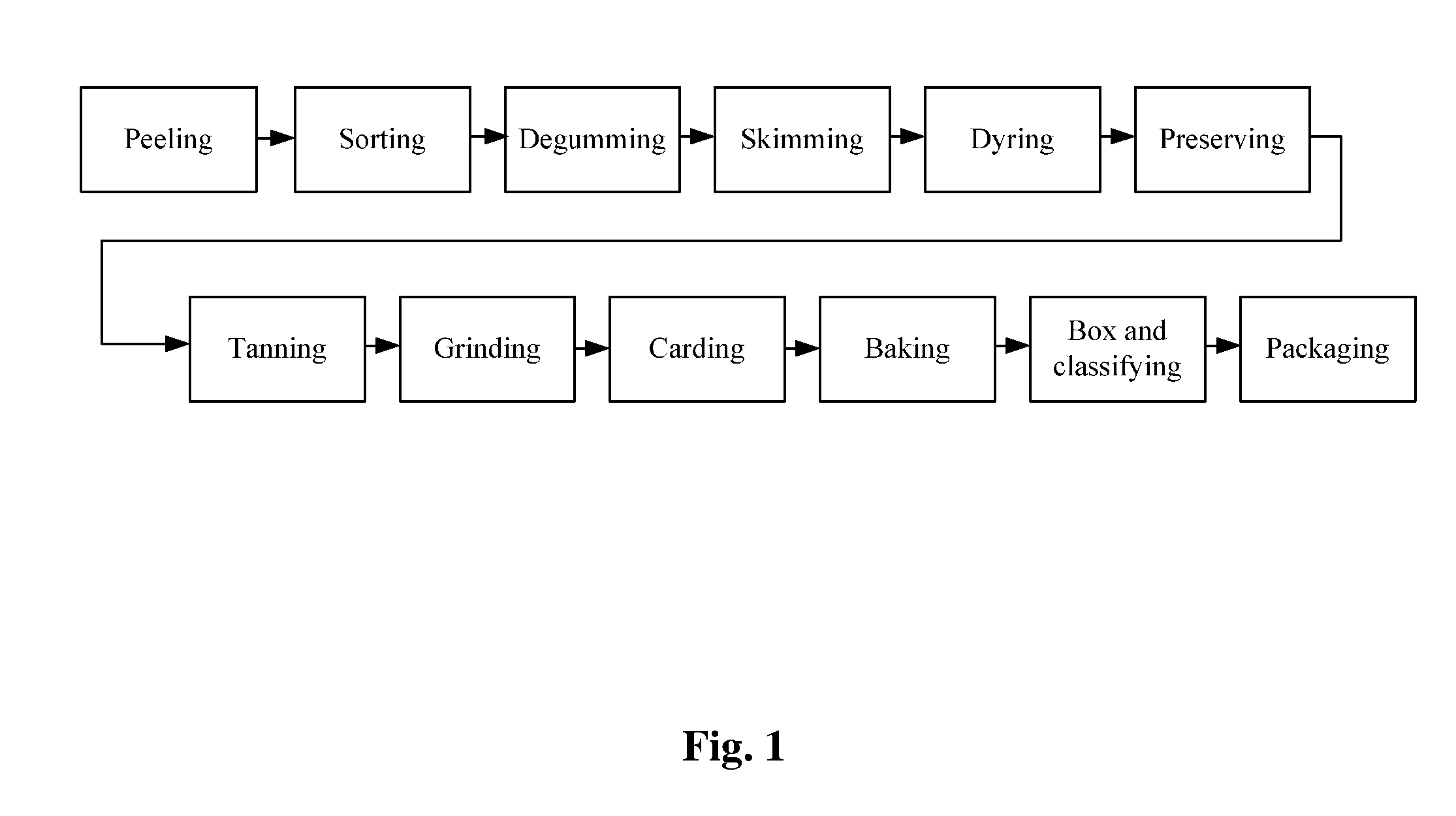

Method used

Image

Examples

example 1

[0028] In this example firtrees were used. Aged bark was manually removed from the surface of the trees. Tree bark was separated from trunks, paying attention so as to avoid introducing a hard lignified fiber layer within the trunk. Tree bark was immersed in a water pool comprising sulfuric acid at a concentration of 12 g / L, and 0.5% by weight of common laundry powder. The temperature was maintained at 60° C. for 12 hours. The obtained product was taken out and dried, and then put into a humidifying bin. Silicon oil-water emulsion was uniformly sprayed thereon, and it was covered and preserved with a canvas for 18 hours. The preserved tree bast fiber was placed into a tanning agent containing Lamepon A, JFC, peanut oil, engine oil and water for tanning. The tanned tree bast fiber was cut into pieces with a size of approximately 70 mm. The cut fiber was opened with a commonly-used fiber opener and then carded 3-5 times through a carding machine. The carded fiber was collected and put...

example 2

[0029] In this example ficus trees were used. Tree bark was manually separated from trunks. Tree bark was immersed in a water pool comprising sulfuric acid at a concentration of 3 g / L, and 1% by weight of common laundry powder. The temperature was maintained at 20° C. for 48 hours. The obtained product was taken out and dried, and then put into a humidifying bin. Silicon oil-water emulsion was uniformly sprayed thereon, and it was covered and preserved with a canvas for 24 hours. The preserved tree bast fiber was placed into a tanning agent containing Lamepon A, JFC, peanut oil, engine oil and water for tanning. The tanned tree bast fiber was cut into pieces with a size of approximately 70 mm. The cut fiber was opened with a commonly-used fiber opener and then carded 3-5 times through a carding machine. The carded fiber was collected and put into a dryer for drying. The tree bast fiber was finally separated into different dimensions using an air separator. The performance of the fib...

example 3

[0030] In this example nerium indicum mill were used. Tree bark was manually separated from trunks. Tree bark was immersed in a water pool comprising sulfuric acid at a concentration of 8 g / L, and 1% by weight of common laundry powder. The temperature was maintained at 50° C. for 24 hours. The obtained product was taken out and dried, and then put into a humidifying bin. Silicon oil-water emulsion was uniformly sprayed thereon, and it was covered and preserved with a canvas for 24 hours. The preserved tree bast fiber was placed into a tanning agent containing Lamepon A, JFC, peanut oil, engine oil and water for tanning. The tanned tree bast fiber was cut into pieces with a size of approximately 70 mm. The cut fiber was opened with a commonly-used fiber opener and then carded 3-5 times through a carding machine. The carded fiber was collected and put into a dryer for drying. The tree bast fiber was finally separated into different dimensions using an air separator. The performance of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com