Spray gun with pressure display

a pressure display and spray gun technology, applied in the field of spray guns, can solve the problems of wasting resources, adding wastes, and rarely using pressure gauges in actual spray coating, and achieves the effects of reducing paint consumption, reducing waste, and reducing was

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

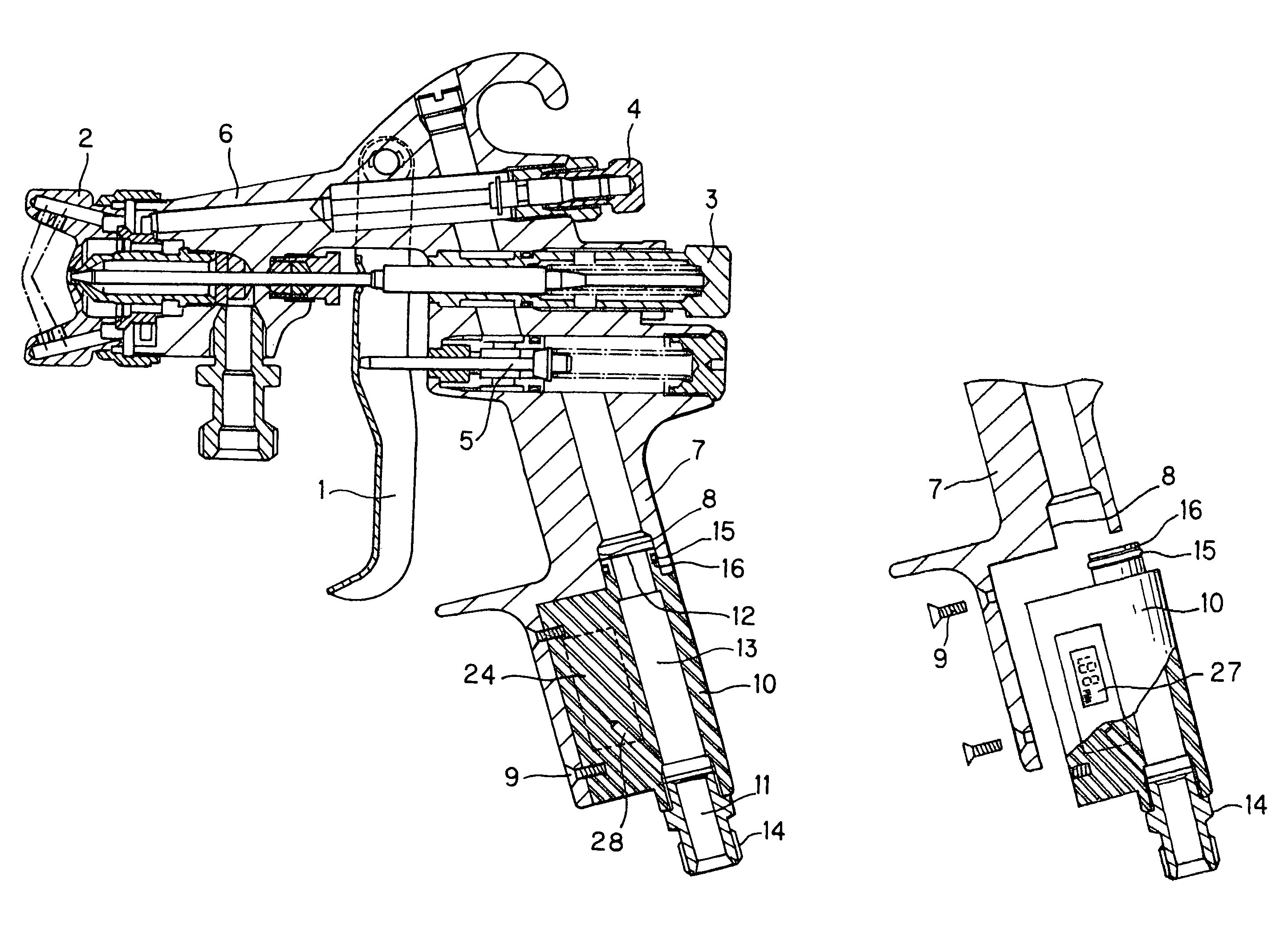

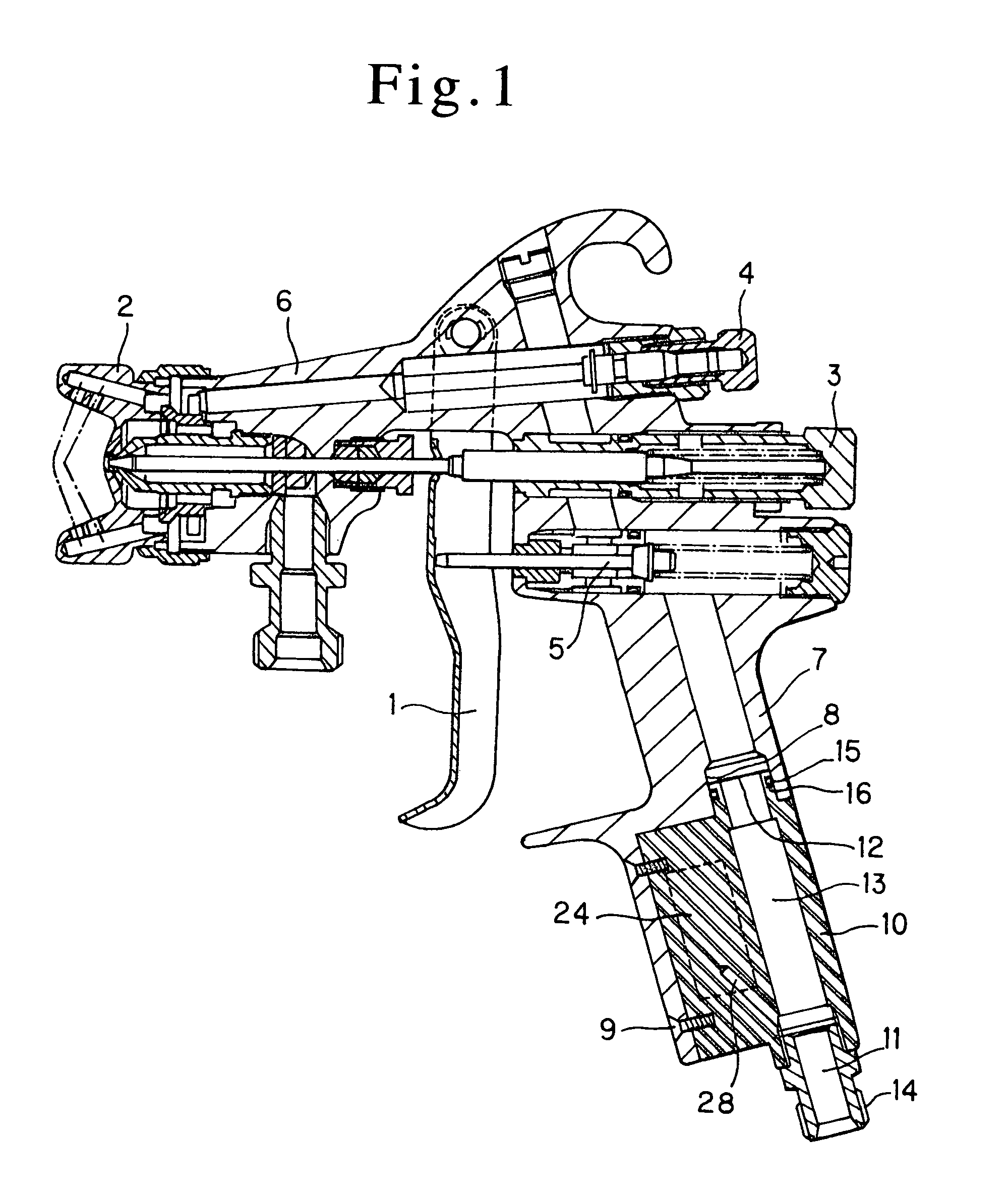

[0032]Referring now to FIG. 1, there is schematically illustrated in the form of a sectional view the spray gun according to an embodiment of the present invention. The spray gun is of a manual type operated by a trigger 1. As shown, the spray gun includes a body and the spray gun body includes a gun barrel 6 having an atomization air cap 2, paint supply adjuster 3, spray pattern adjuster 4 and an air valve 5, and a grip 7 extending backward and downward from the gun barrel 6. A pressure indication unit 10 is removably fixed to the lower end of the grip 7, and thus forms a part of the grip 7.

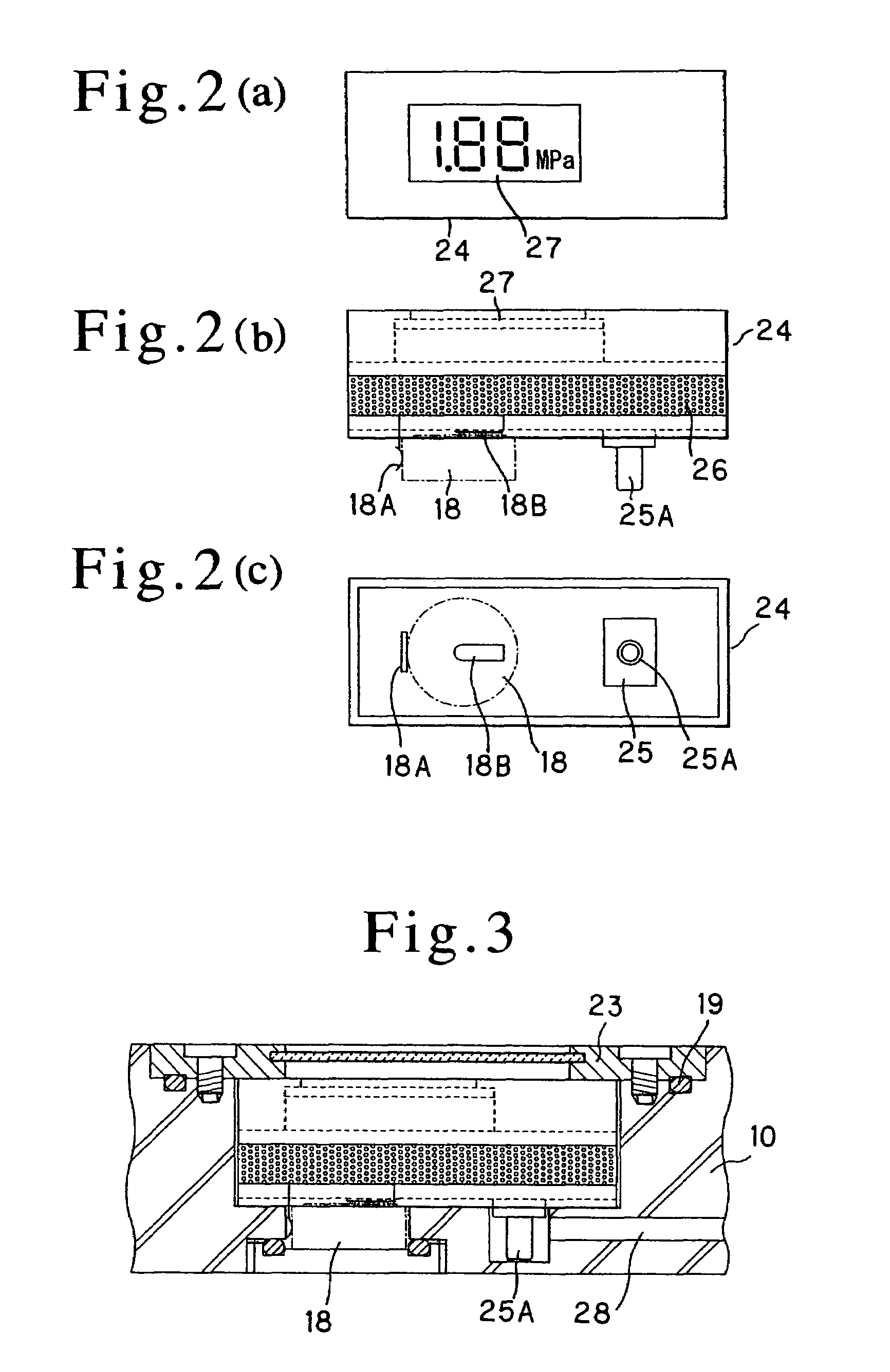

[0033]The pressure indication unit 10 has a compressed air intake 11 formed at the lower end thereof. The compressed air intake 11 communicates with a central air channel 13 extending to a portion 12 for coupling to the spray gun body, formed at the upper end of the pressure indication unit 10. The pressure indication unit 10 is externally threaded (indicated at a reference 14) on the outer surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com