[0001]This invention is related to

washer-extractor machines and in particular to drum type washing machines that provide saving from water, energy and time and at the same time increase washing and extraction efficiency. The machine according to this invention prevents the harm of the

textile caused by the drum perforations and also during the high speed

spinning stage. This invention is also related to a washing and rinsing process realized using this machine.

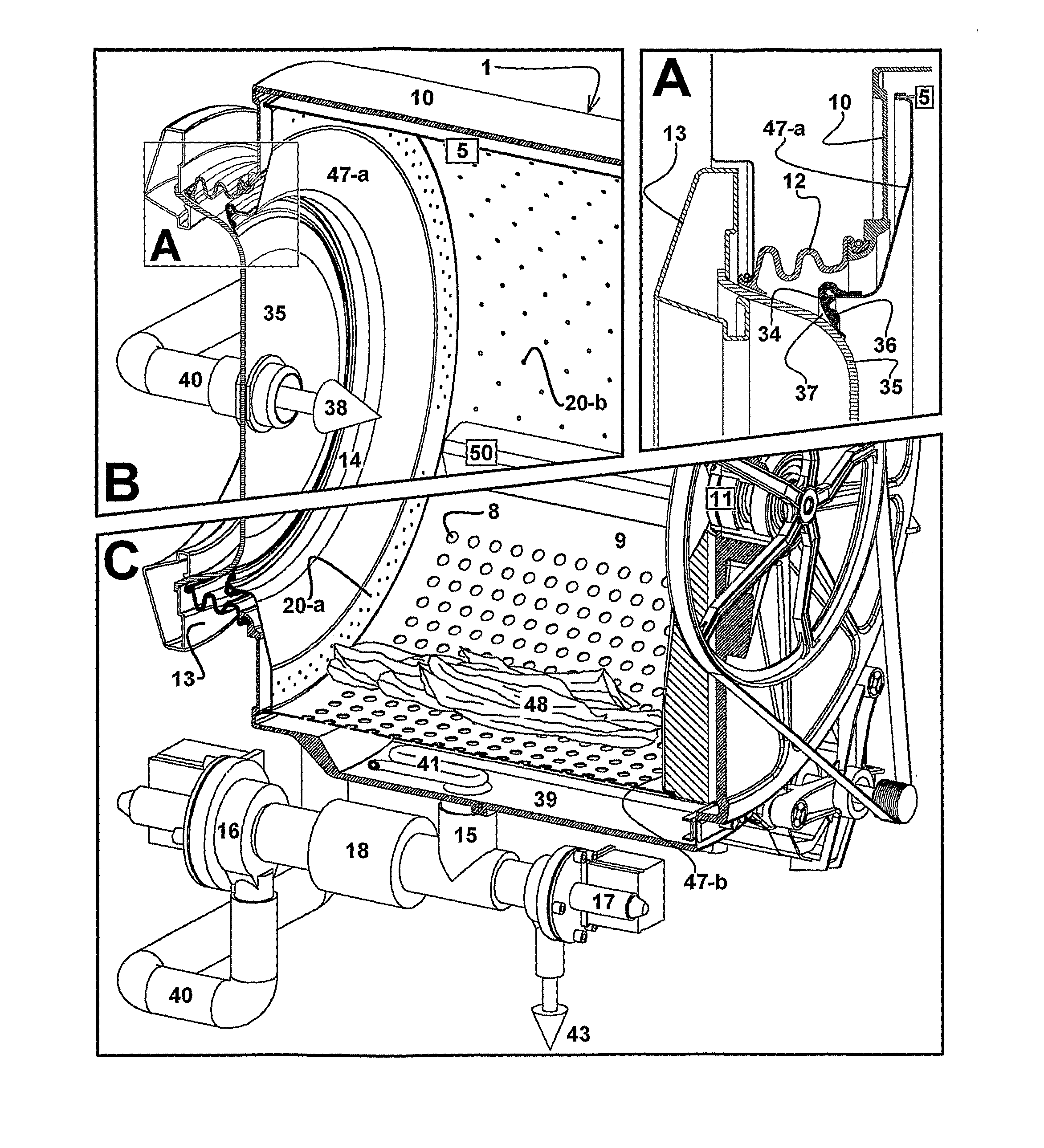

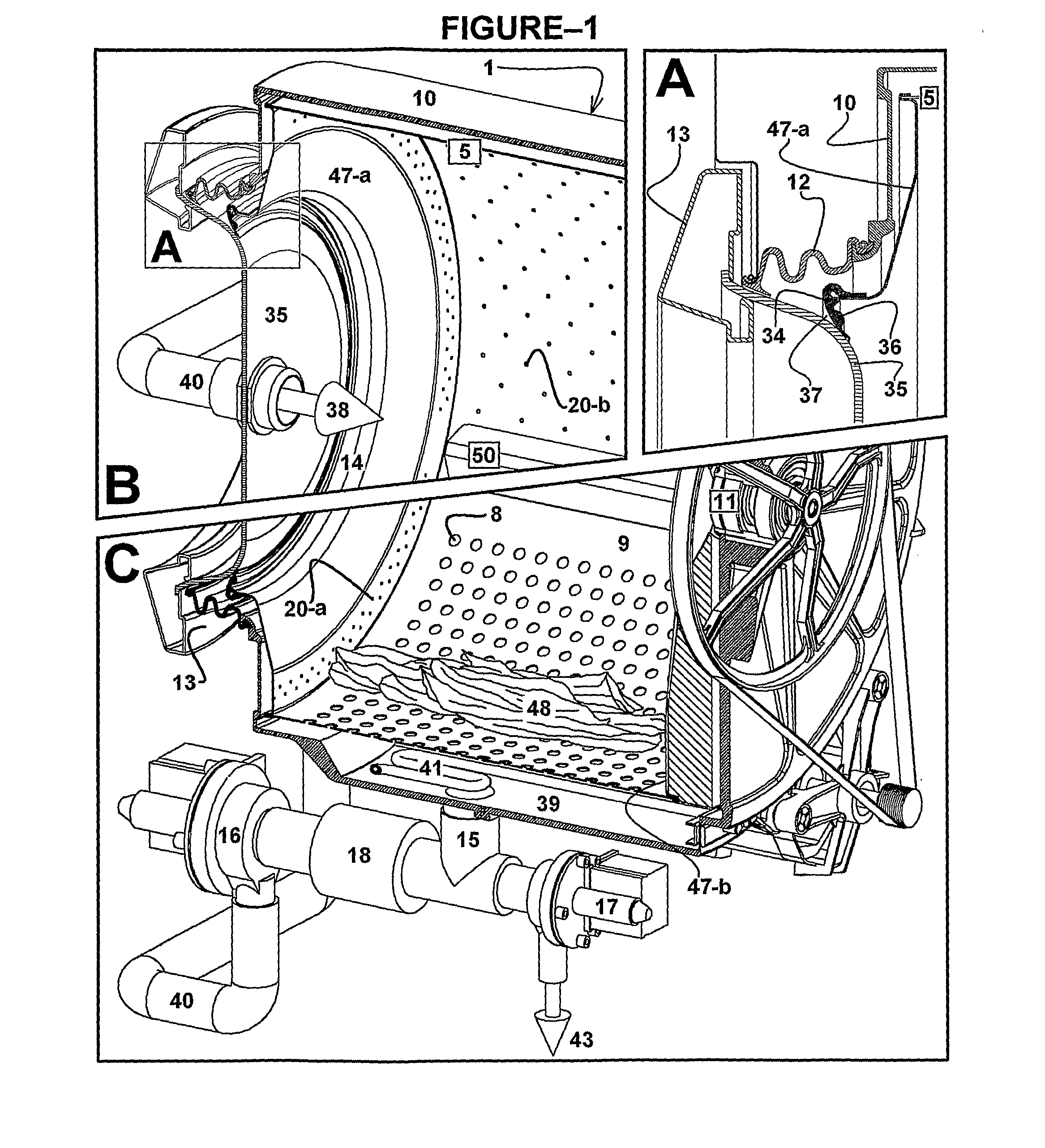

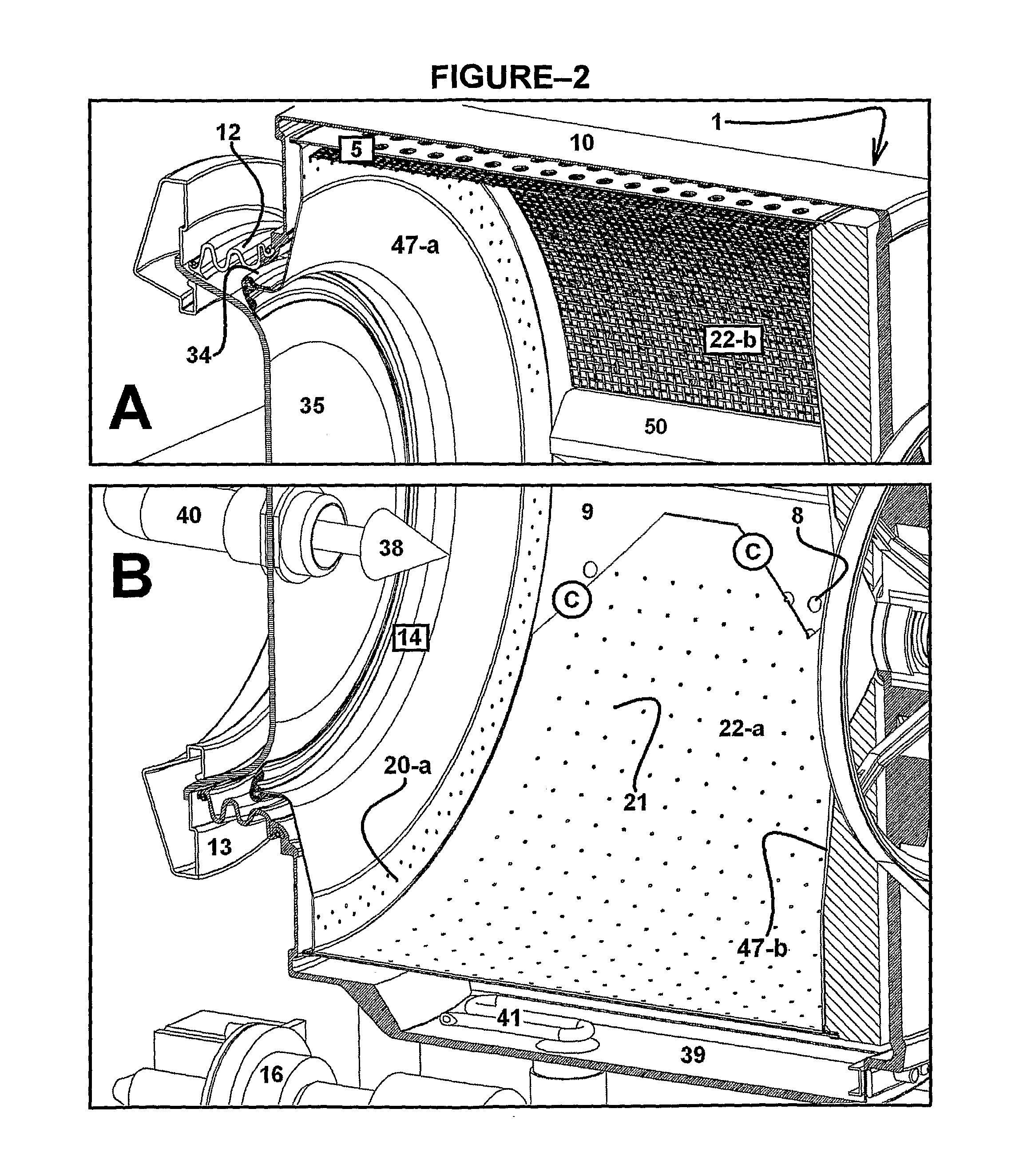

[0005]In order to fill the drum with liquid such as water or, to heat water, to mix chemicals into water, to measure

water temperature, to measure

water level, to drain water, and to collect liquid draining out through the drum perforations during a

spinning cycle, a tub is needed outside the drum, and in order to prevent said drum to contact said tub while spinning, a space is necessary in between. When washing liquid required for a washing process is taken inside a tub, the amount of liquid filling the space between said tub and the drum corresponds to nearly 15-35% of necessary liquid. Liquid draining from a limited permeability drum can be restrained and flow back is maintained therein by means of a pump which has a higher flow-rate than that permeated water, enabling therefore an evacuation of the volume between the drum and the tub while at the same time an adequate amount of liquid existing inside the drum. The drum, which constitutes the object of the invention, provides considerable savings of water, energy, chemicals, and time by means of emptying said

exterior space during a washing process. Saving of water and chemicals is important as far as consumption is concerned and also it is vital to decrease the amount of waste water contaminated with chemicals, thus preventing environmental

pollution.

[0006]During a washing process, the interaction of water and / or chemicals with washed materials inside a drum is achieved by lifting and falling movements of said materials, which obtained with the drum rotation. Conventional perforated drums contain lifter beaters which are called ribs in sizes proportional to the

diameter of the drum. In washing machines using less water, rib heights varies approximately between 6 to 12% of the

diameter of the drum, while this proportion reaches 12 to 20% in machines using more water. The size of said ribs should enable lifting a considerable amount of the

laundry mass. In conventional washing machines, the number of ribs is limited to 6 or maximum 8. Washing is both a chemical and a physical process. One other important function of washing machines is to extract liquid from processed material by way of a

centrifugal force produced from spinning of drum at high speeds. Due to

centrifugal force, extracting pressure at high speeds may attain values up to 400-500 G; and in the case of high capacity machines, wherein

laundry stretches very tightly over ribs, and spaces remain underneath between the ribs and drum sheet, such

physical pressure may applied to said

laundry to stretch towards the spaces and causes damages or tearing. On the other hand, laundry over the ribs, placed during distribution, is more close to the rotation axis, means it undergoes less

centrifugal force, and more liquid remains thereon. If material is lifted by means of many small ribs or protrusions scattered in very short intervals and homogeneously over the cylindrical surface of a drum, said drum constituting the object of the invention, any damage caused to textile by normal size ribs can be prevented. Height of said small ribs and protrusions indicated here is approximately between 1 to 6% of the

diameter of said drum.

[0007]Protrusive cylindrical surface of a drum also provides other advantages besides the facility of lifting washing material. Such protrusive structure, augments the physical effect while washing, helps to rotate the material in more homogeneous and more regular manner, enables better distribution of laundry inside the drum at the start of extraction and orients extracted water towards the perforations. During extraction phase, textile dispersed over a usual perforated cylindrical surface gets more and more squeezed as centrifugal force increases pressure thereon, which restrains not only water passage through the textile fibers, but also drainage ways through the drum perforations. Water drainage from a drum can be accelerated by employing adequately elevated and dense protrusions that are provided in the present invention, in which situation laundry will stretch towards the spaces between the protrusions but will not reach to block the perforations. Draining more extracted water at an equal spinning speed and

equal time is provided and in return improved extraction efficiency without any change in the

energy consumption is obtained.

[0009]The invention disclosed in the present application provides savings from water, energy, chemicals and time consumption as attempted by the foregoing references, through limiting

water use by the strictly necessary amount for the inner drum, enabling implementation in all types of perforated drums horizontal or inclined with the horizontal, independent from

water level or the amount of fabrics loaded therein. Moreover, as explained below in several embodiments, the application of methods, corresponding to the purpose of the present invention, has been reduced to such basic essentials that no alteration is required in the production techniques of conventional and commonly used horizontal washing machines. Providing the cylindrical surface of a drum with perforations as in ordinary drums, and enabling water drainage through said perforations during both drain and extraction cycles prevent not only efficiency loss in washing and extraction but also the creation of new problems.

Login to View More

Login to View More  Login to View More

Login to View More