Electrochemistry stripping and reducing integrated graphene preparation method

A graphene and electrochemical technology, which is applied in the field of graphene preparation integrating electrochemical exfoliation and reduction, can solve the problem that graphene oxide sheets are folded into worm-like shapes, the lateral sizes of graphene are different, and the graphene preparation process is cumbersome. Complexity and other problems, to achieve the effect of low cost of raw materials, low cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

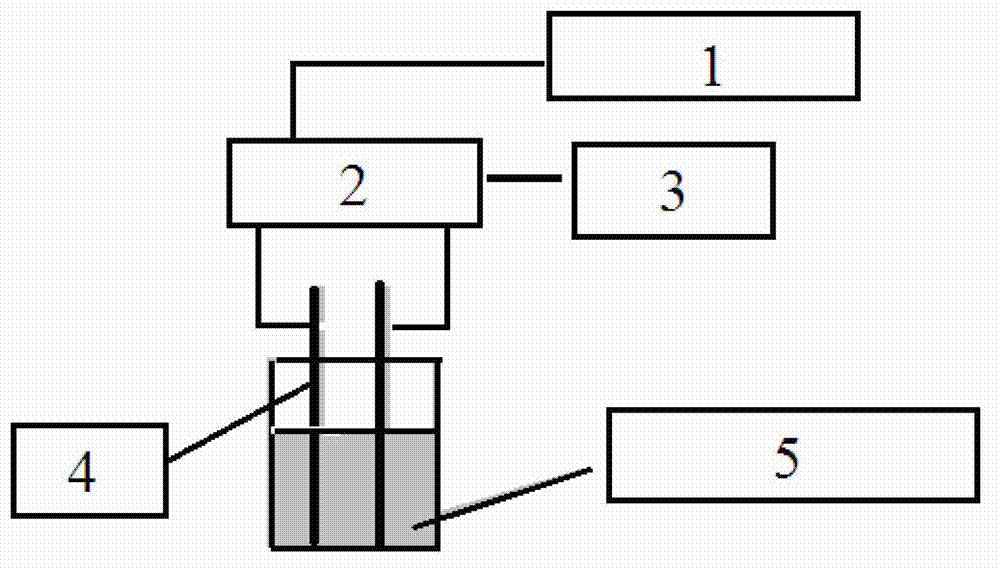

[0032] The device of this embodiment is as figure 1 As shown, the signal generator 1 is connected to the power amplifier 2, and the power amplifier 2 is connected to the electrode 4, wherein the power amplifier 2 is connected to the oscilloscope 3 that detects the frequency and waveform of the electrical signal at the same time, and the graphite oxide aqueous solution 5 is applied to the alternating current through the signal generator 1. electric field.

[0033] The reaction time of the present embodiment is 120 minutes.

[0034] First, 30 μm natural graphite was used as raw material to prepare GO by the improved hummers method; the obtained GO was dissolved in deionized water to prepare a 0.2 mg / ml GO suspension; a self-made electrochemical reaction glass container (length 4 cm, width 2 cm, height 10 cm ) and two copper electrodes (3.5cm in width and 10cm in length), insert the two copper electrodes into the glass container with a distance of 2cm between the two electrodes,...

Embodiment 2

[0039] The device of this embodiment is as figure 1 Shown, reaction time 90 minutes.

[0040] First, 30 μm natural graphite was used as raw material to prepare GO by the improved hummers method; the obtained GO was dissolved in deionized water to prepare a 0.2 mg / ml GO suspension; a self-made electrochemical reaction glass container (length 4 cm, width 2 cm, height 10 cm ) and two copper electrodes (3.5cm in width and 10cm in length), insert the two copper electrodes into the glass container with a distance of 2cm between the two electrodes; 0.5Hz, duty cycle 20%, voltage 40V); pour 50ml of the prepared GO suspension into a glass container, turn on the power, stop the reaction after 90 minutes of reaction, and obtain high-quality rGO;

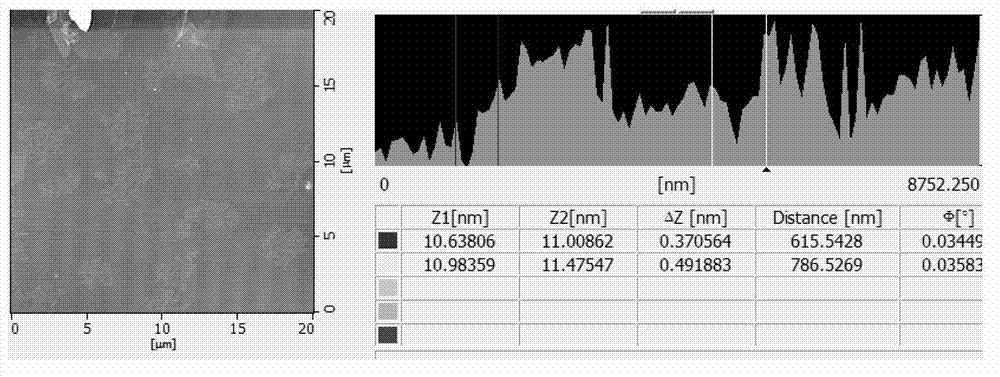

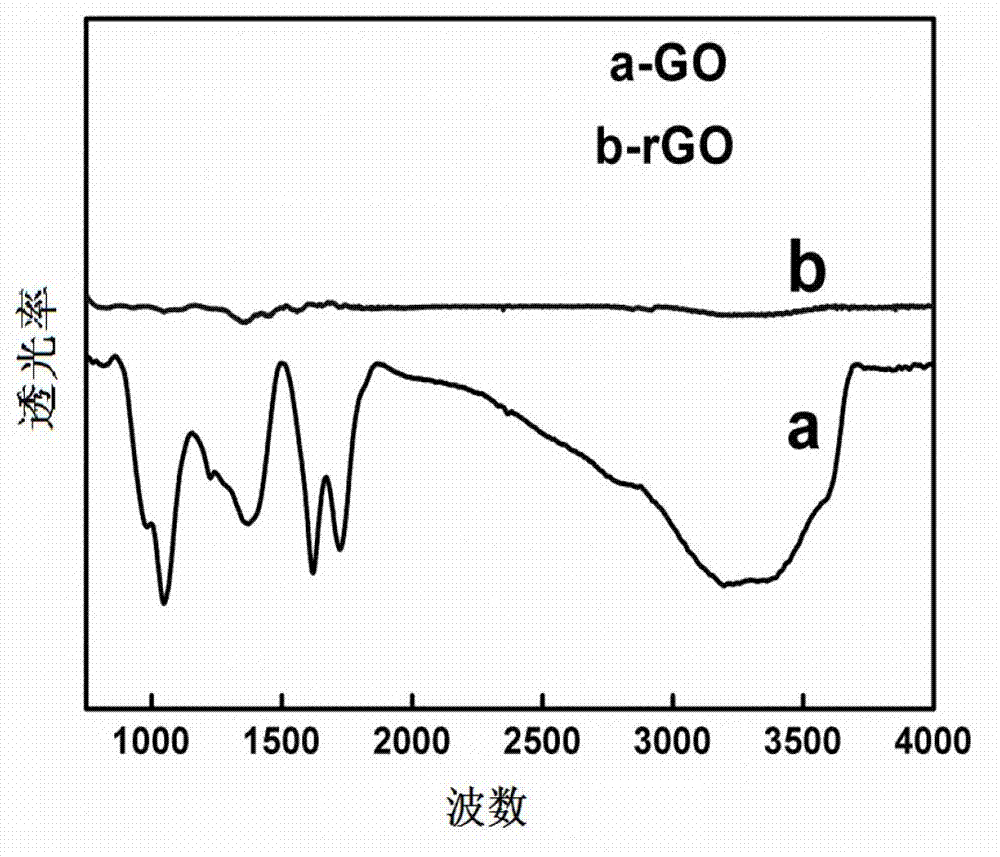

[0041] The obtained rGO was analyzed by atomic force microscope, infrared spectrum and X-ray diffraction to verify its reduction. The results are as follows: Figure 5 , Figure 6 and Figure 7 shown.

[0042] From Figure 5 It can be see...

Embodiment 3

[0046] A kind of graphene preparation method of electrochemical exfoliation and reduction integration, the method comprises the following steps:

[0047] (1) Dissolve graphite oxide in deionized water to form a graphite oxide solution with a concentration range of 0.1 mg / ml;

[0048] (2) graphite oxide solution is added in the reaction vessel, and the reaction vessel can be a glass or plastic container;

[0049] (3) applying an alternating electric field in the graphite oxide solution;

[0050] (4) Graphite oxide reacts electrochemically in the environment of alternating electric field to generate graphene.

[0051] The method of applying the alternating electric field in step (3) is as follows: the signal generator outputs the signal, and the signal is input into the power amplifier. Frequency, output the amplified electrical signal to the electrode, that is, an alternating electric field is obtained. The distance between the two electrodes is 0.5cm, the electrodes are cop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com