Method for recycling, cleaning and granulating waste mulching films

A processing method and mulching technology, applied in the direction of plastic recycling, recycling technology, etc., can solve environmental pollution, damage to soil quality, waste of resources, etc., to achieve the effects of avoiding environmental pollution, improving production efficiency, and recycling resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

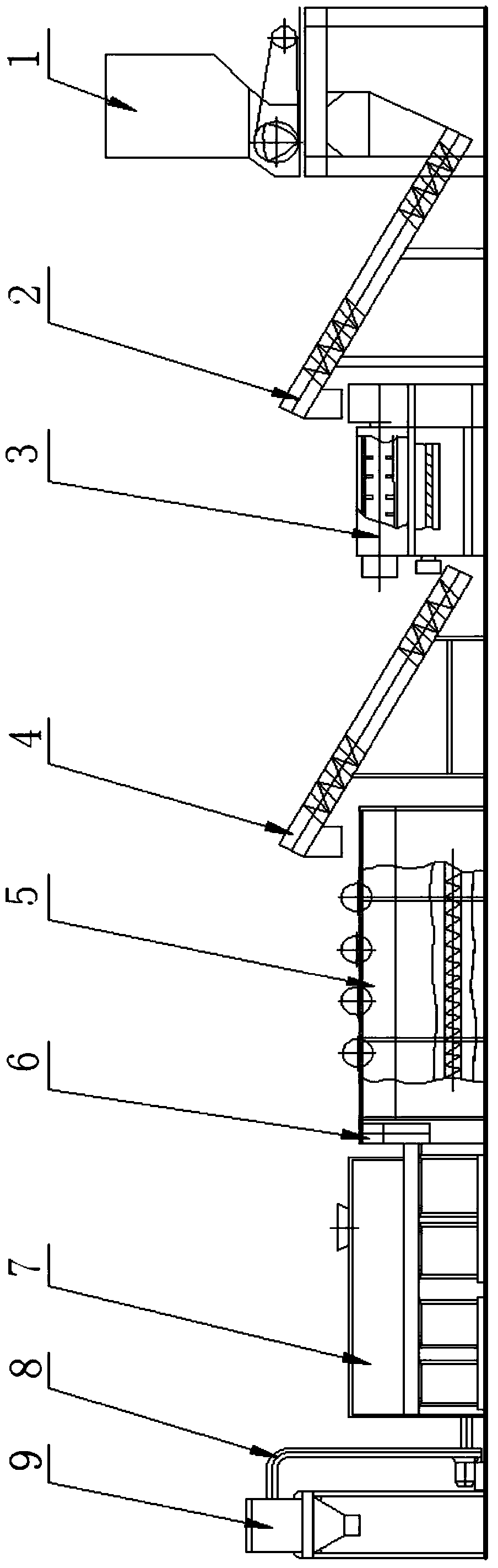

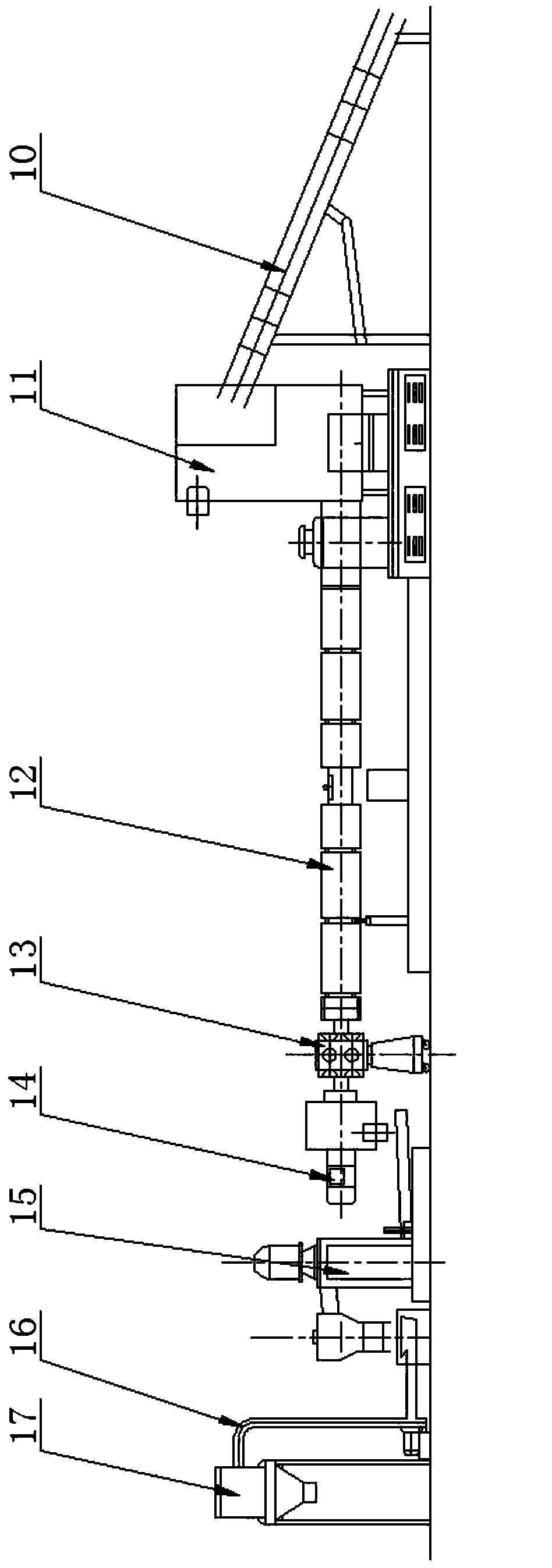

[0025] exist figure 1 Middle: The flow of equipment used in the cleaning process is film crusher 1→screw feeder Ⅰ2→friction cleaning machine 3→screw feeder Ⅱ4→rinsing tank 5→screw feeder Ⅲ6→squeeze dryer 7→air delivery system 8→storage Bin 9. Waste plastic film cleaning is a fully automatic 1500-2000kg / h PE film cleaning production line. The power supply is 380V, 50Hz, 3 phases; the installed power is about 220KW; the actual power consumption is about 130-160KWH; the water consumption is 10-15 tons of circulating water, and the water loss is 2-3 tons / day; the equipment covers an area of about 300m 2 , can be arranged according to the workshop, 2-3 workers / shift. Screw feeder I2, screw feeder II4 and screw feeder III6 are the same. The above-mentioned equipments are purchased parts.

[0026] Cleaning has the following sequential steps:

[0027] ① The recovered waste plastic film is classified and sorted for pretreatment, and then manually coarsely crushed. The purpose o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com