Large thin-walled component complex curved surface mirroring processing method

A technology for thin-walled parts and complex curved surfaces is applied in the field of mirror processing of complex curved surfaces of large thin-walled parts, which can solve the problems of difficult to guarantee processing quality and low processing efficiency of large thin-walled workpieces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The embodiments of the present invention will be described in detail in conjunction with the drawings and technical solutions.

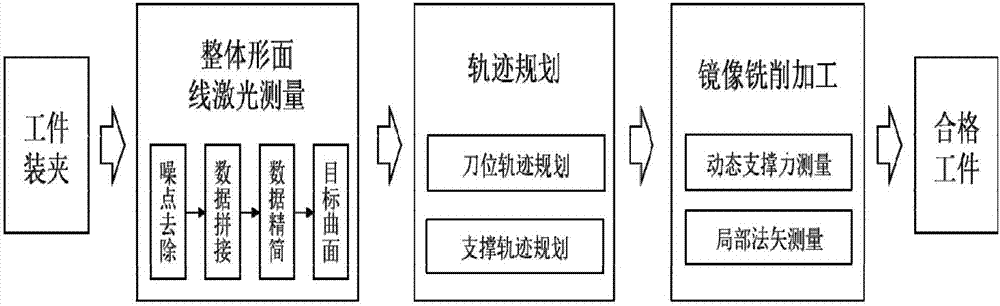

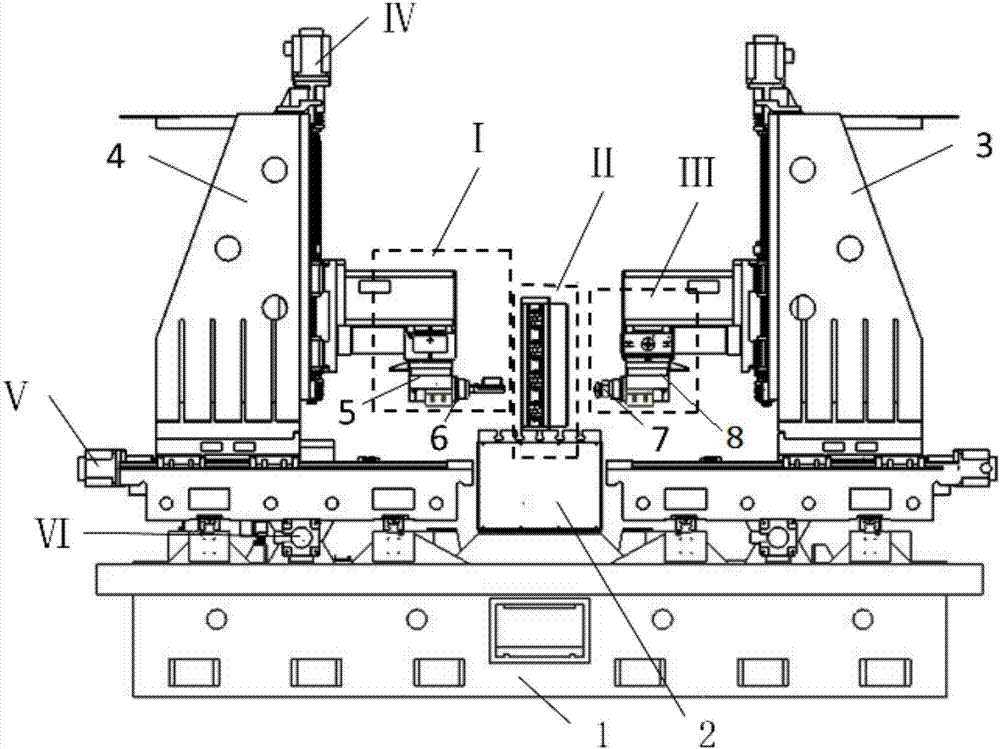

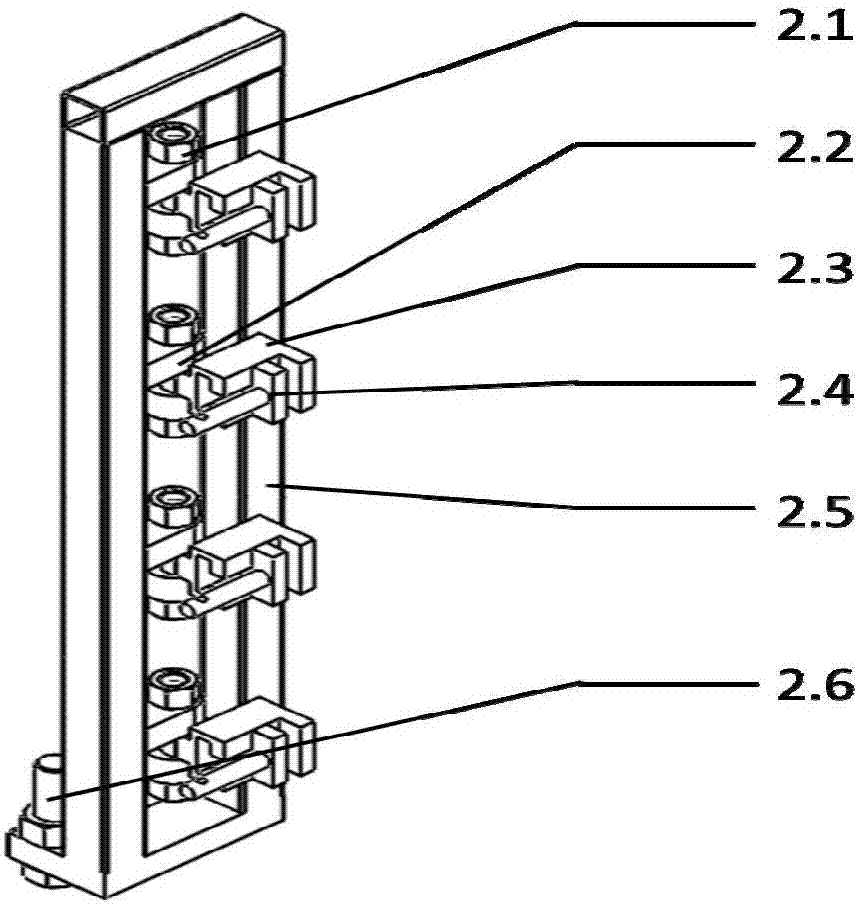

[0048] The thin-walled part to be processed is a three-dimensional curved surface with irregular shape. The cutting tool should be controlled according to the actual value of the surface profile and the required theoretical removal amount. The machine tool is required to have not only the milling function of the curved surface, but also the measurement function of the curved surface. Therefore, the mirror image processing equipment for thin-walled parts of the present invention is a digital special equipment integrating measurement and milling. Complete the measurement and milling process of thin-walled parts in one clamping, so as to eliminate or reduce the installation error of thin-walled parts measurement and milling. Since the processed thin-walled parts have different sizes and the shape may change during the clamping process, it is nece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com