Prelithiation method and prelithiation device for negative electrode of lithium battery

A lithium battery and negative electrode technology, applied in the field of lithium battery negative electrode pre-lithium method and pre-lithium device, can solve the problems of positive and negative electrode dead lithium increase, lithium consumption, material lithium loss, etc., achieve better rolling effect, mechanism setting Simple, even roll pressure results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

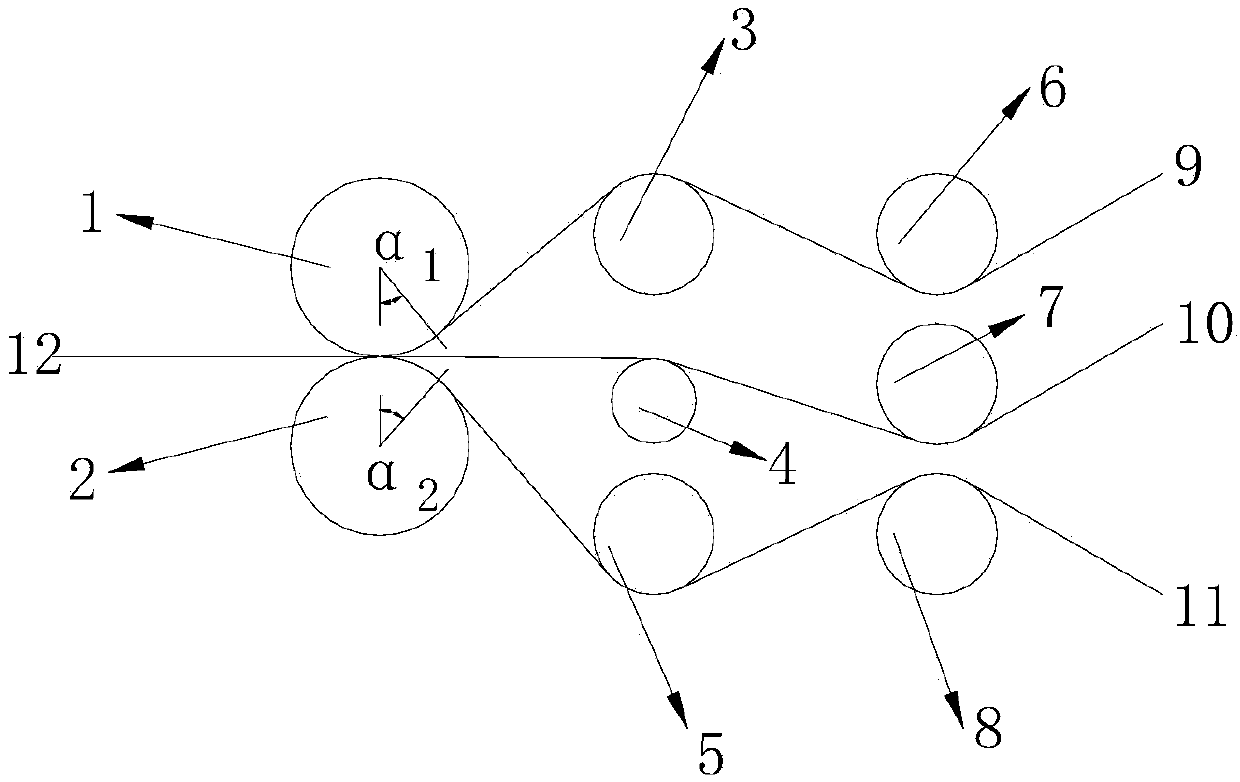

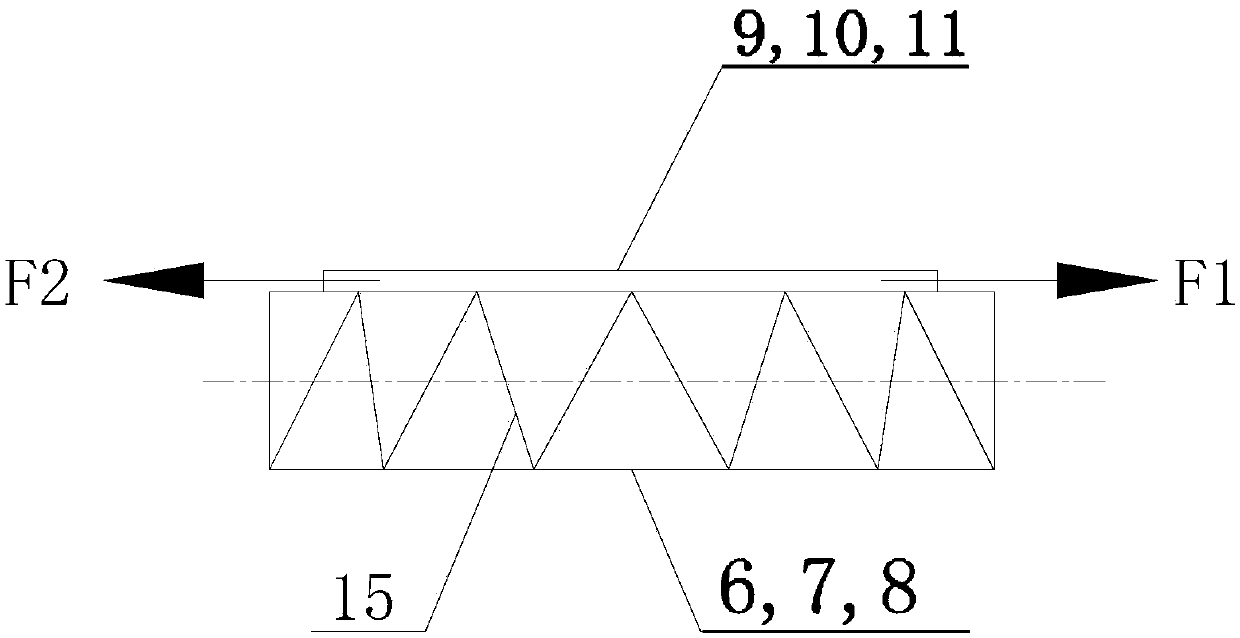

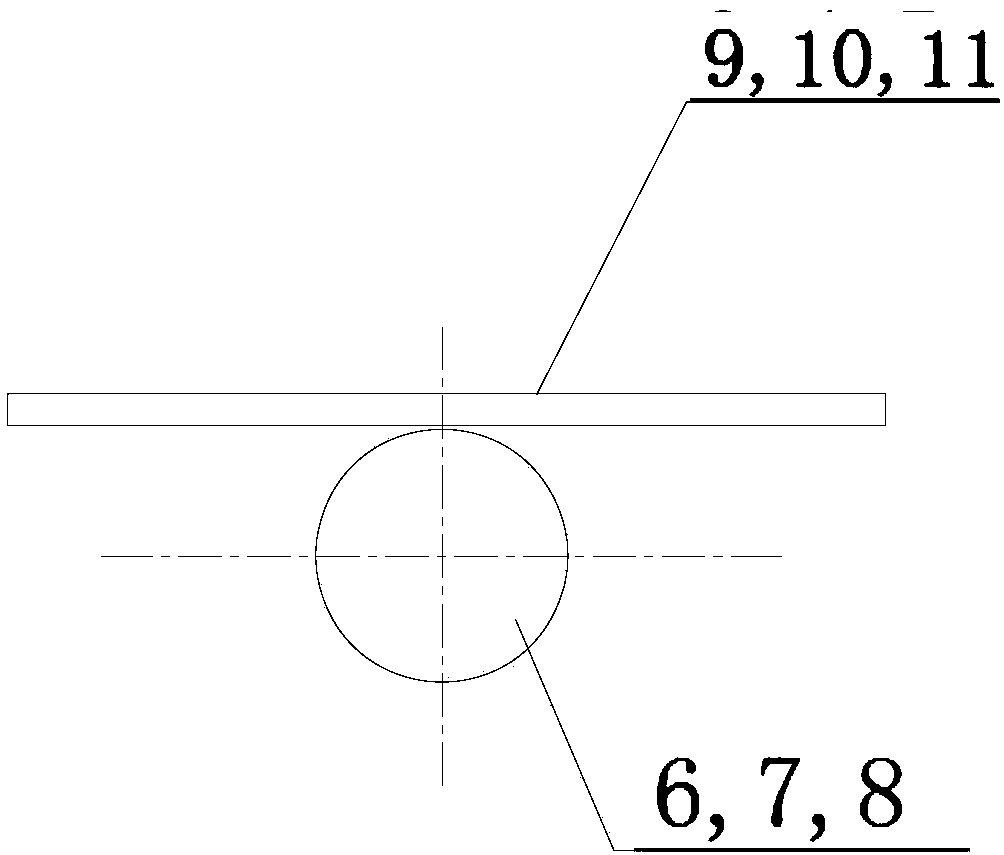

[0027] The present invention will be described in detail in conjunction with accompanying drawing now. This figure is a simplified schematic diagram only illustrating the basic structure of the present invention in a schematic manner, so it only shows the components relevant to the present invention.

[0028] A kind of lithium battery negative pole pre-lithium method of the present invention comprises the following steps:

[0029] Step 1: Flatten the copper foil 10 or the lithium foil so that the lithium foil is located on both sides of the copper foil 10, guide the copper foil 10 and the lithium foil, and then send them into the gap between the two set pressure rollers for rolling , and make the lithium foil and the pressure roller on the same side have a wrap angle, and form a pre-lithium composite copper foil 12 after rolling;

[0030] Step 2: After the pre-lithium composite copper foil 12 material is coated with the negative electrode material and rolled twice, the pre-li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com