Integrated asphalt road surface planing and milling repair vehicle

An asphalt pavement and integrated technology, which is applied in the field of machinery and equipment, can solve the problems of simultaneous recycling and laying of new asphalt layers, low operating efficiency, and high engineering cost, etc., to achieve reduced engineering construction costs, easy process, and rolling outstanding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

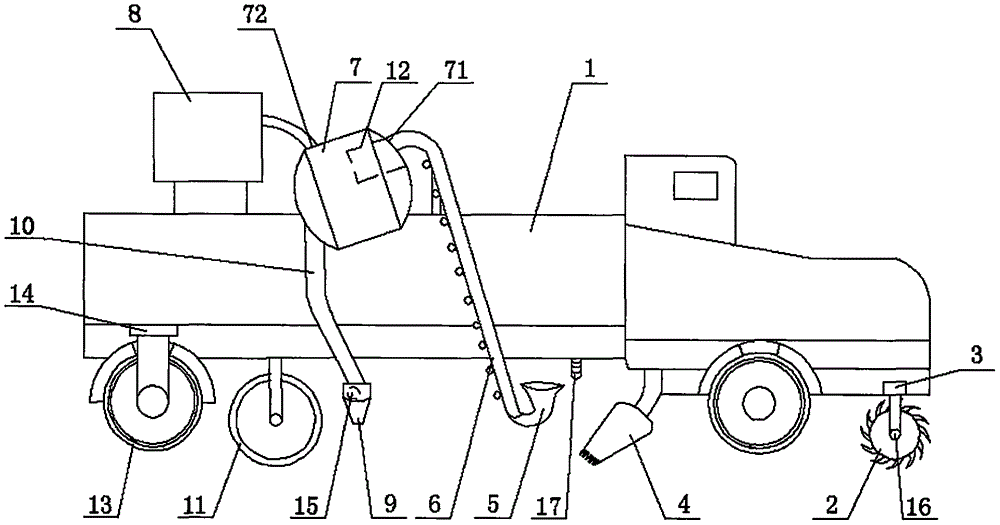

[0024] like figure 1As shown, the integrated asphalt pavement planing and milling repair vehicle of the present invention includes a car body 1. The car body 1 here can adopt a traditional car body structure, that is, it is composed of a front and a car body. In this case, it is collectively referred to as a car body. A planer milling cutter 2 for crushing road asphalt is installed at the front end of the bottom of the car body 1. The planer miller 2 is connected to the car body 1 through a first lifting mechanism 3, and the first lifting mechanism 3 is driven by a hydraulic cylinder. . In order to improve the crushing effect on the damaged road surface, at least three planer milling cutters 2 are installed at the bottom of the car body 1, and the planer milling cutters 2 are all sleeved on the rotating shaft 16 arranged horizontally. A mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com