High-efficiency crushing grinder for food processing

A high-efficiency pulverization and food processing technology, applied in the direction of deboning shears/bone crushers, grain processing, etc., can solve the problems of waste of resources, easily damaged pulverizers, deep processing and high-value utilization ratio of less than 5%, etc. The effect of convenient cutting, convenient crushing, cutting and conveying is simple and convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

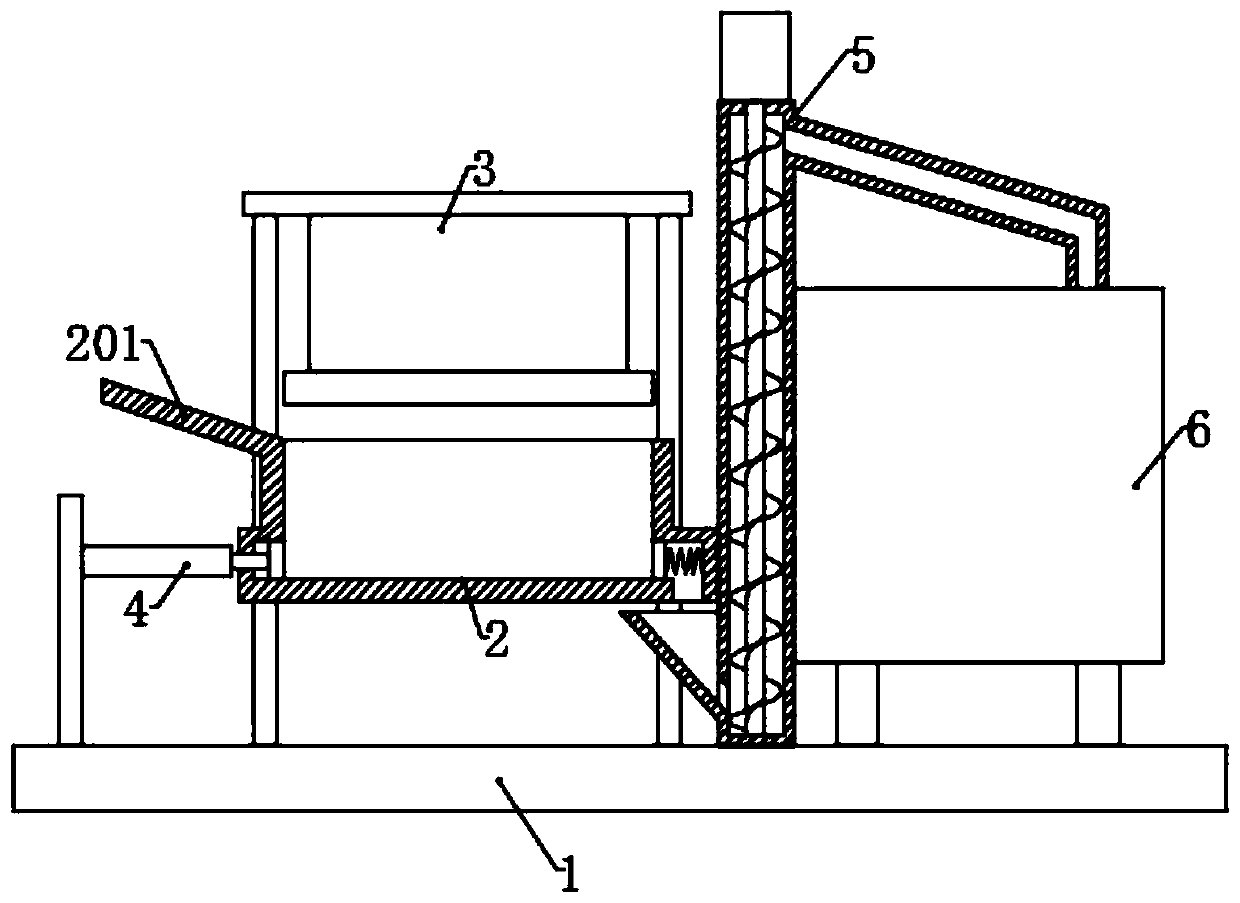

[0038] Please refer to the accompanying drawings, the present invention provides a technical solution: a high-efficiency crushing and grinding machine for food processing, including a base 1, a crushing box 2, a conveying mechanism 5 and a crushing box 6, the crushing box 2 and the crushing box 6 They are respectively arranged on both sides of the top surface of the base 1, and a crushing mechanism 3 is arranged above the crushing box 2, and a feeding mechanism 4 is arranged on the left side, and is connected with the crushing box 6 through a conveying mechanism 5. The box 6 is provided with a crushing assembly, a rolling table 11 and a rolling mechanism 12 .

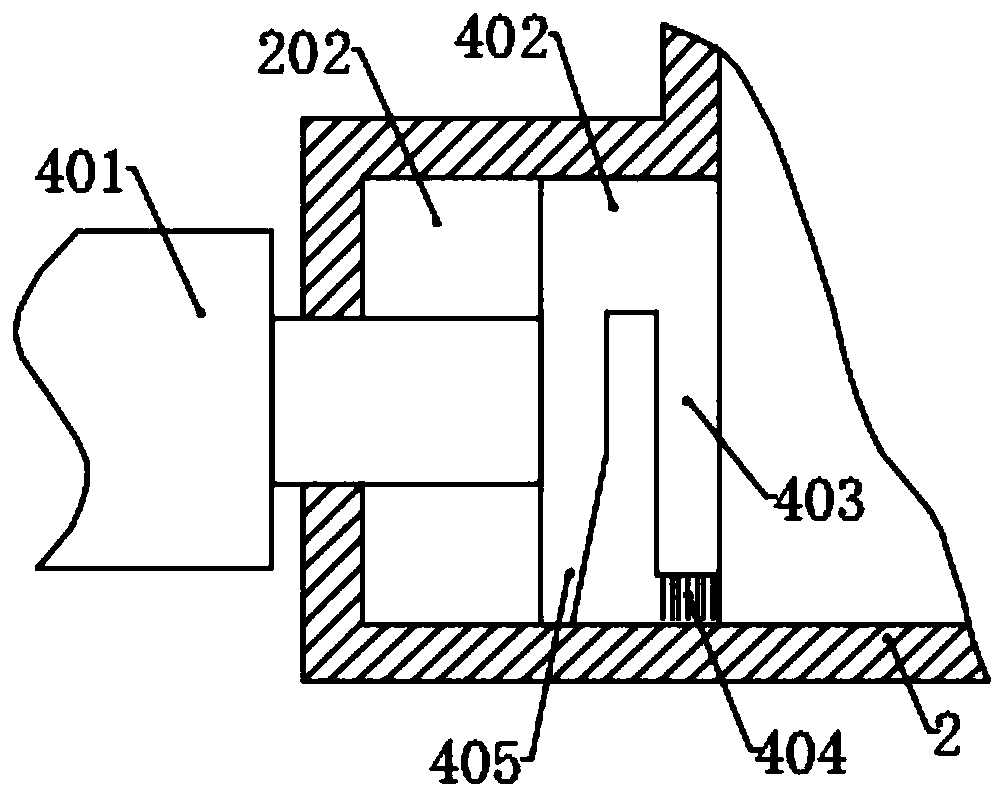

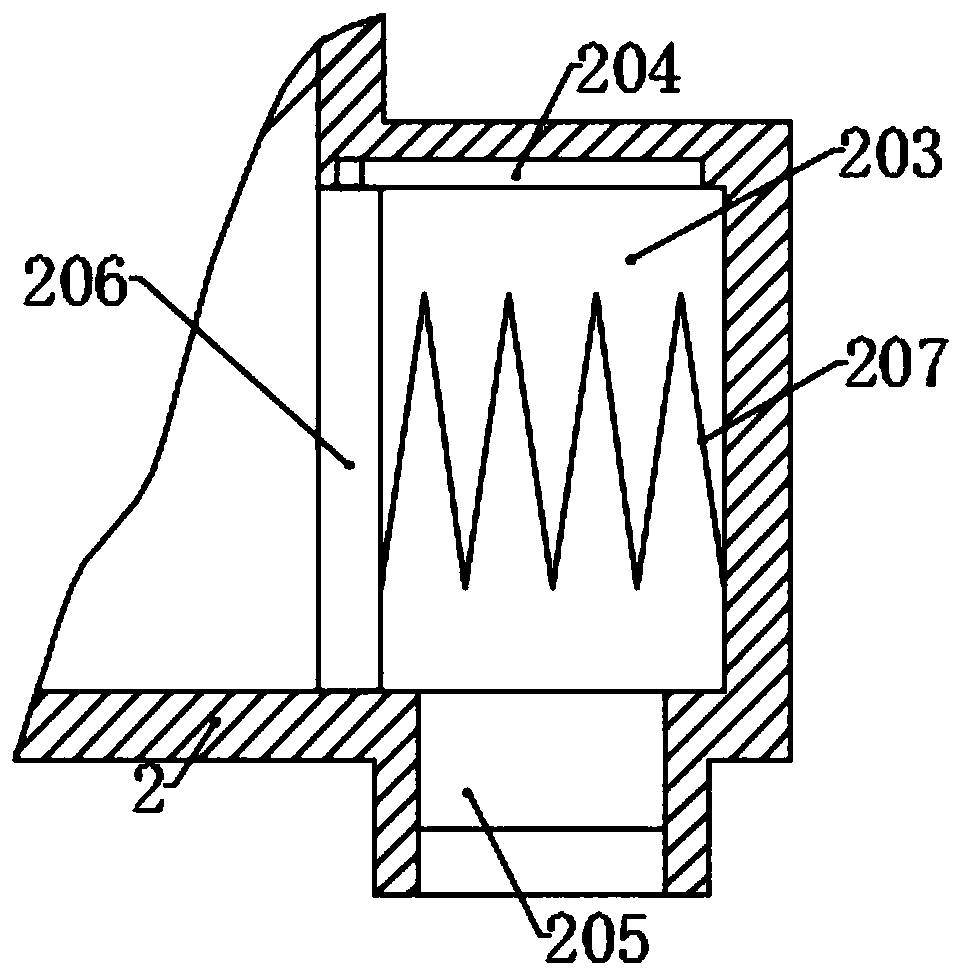

[0039] The top left side of the crushing box 2 is fixed with an inclined material guide plate 201, the bottom surface is uniformly provided with pointed protrusions, the left side is provided with a first plate groove 202, and the right side is provided with a second plate groove 203. The blanking mechanism 4 includes a...

Embodiment 2

[0048] On the basis of Embodiment 1, it also includes a storage box 7 and a feeding mechanism 8, the bottom of the storage chamber is provided with a feeding pipe 701, and one side of the feeding pipe 701 is provided with a discharge groove 702. The feeding mechanism 8 includes a driving cylinder, a driven cylinder and a conveyor belt 801 , and a conveying motor 505 is connected to the driving cylinder.

[0049] The livestock bones after processing are stored in the storage box 7, and then when feeding, they fall onto the conveyor belt 801 through the feeding tube 701, and the bottom end of the feeding tube 701 is close to the conveyor belt 801, so as to avoid bones directly along the conveyor belt 801. Conveying falls in the opposite direction. During conveying, the bones are sent out from the discharge trough 702, move obliquely upwards through the conveying mechanism 5, fall on the material guide plate 201 and enter the crushing box 2, and then carry out subsequent crushing,...

Embodiment 3

[0051] On the basis of the second embodiment, the surface of the conveyor belt 801 is uniformly provided with a plurality of anti-slip convex strips 802 .

[0052] Anti-slip convex strips 802 are provided on the conveyor belt 801 to further prevent the transportation from being blocked due to the movement of the bones to the collision.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com