Aluminum alloy hard foil for battery collector

A technology of battery collection and aluminum alloy, which is applied in the direction of battery electrodes, electrode carriers/current collectors, secondary batteries, etc., can solve the problems of production line stop, foil breakage, etc. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

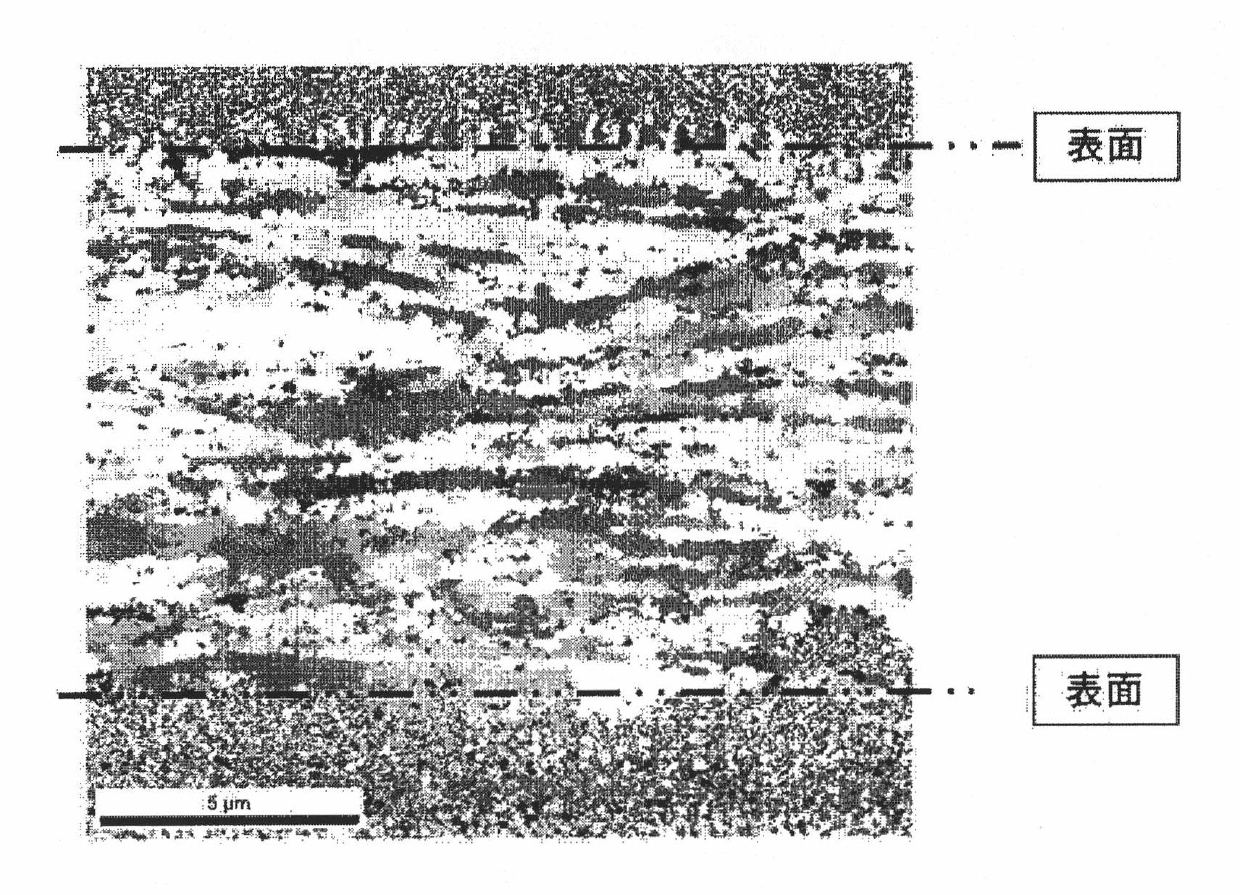

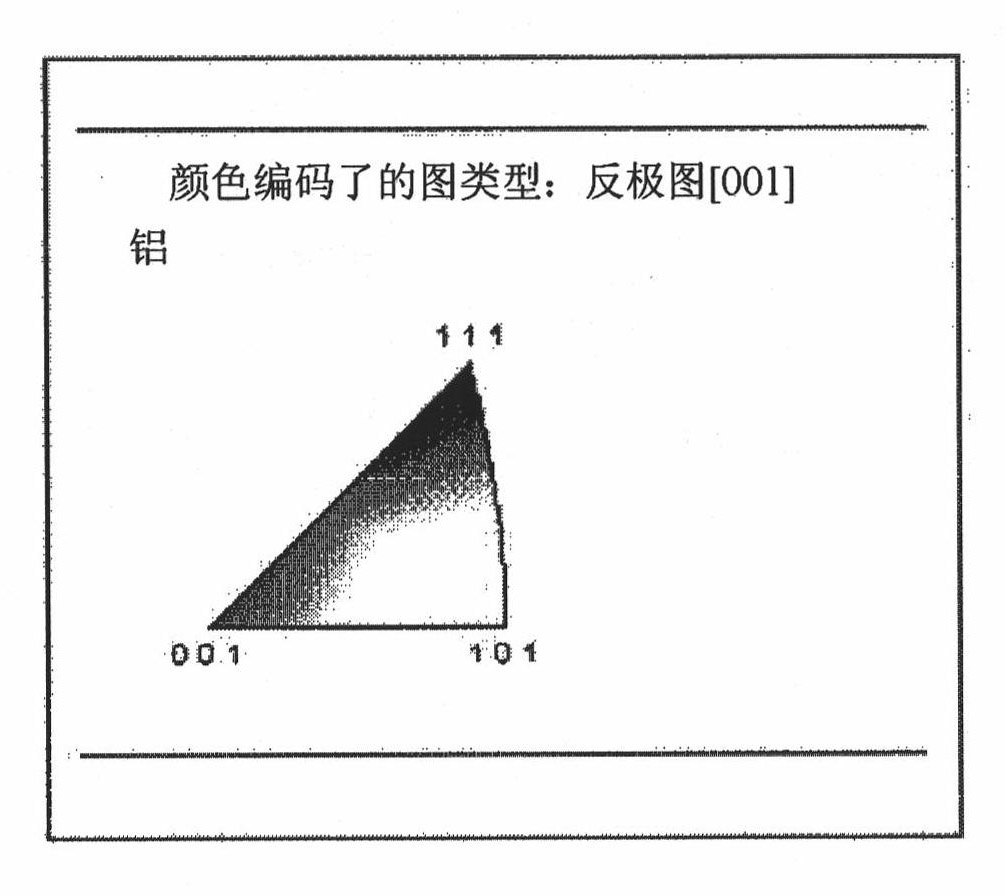

[0073] First, an example of an aluminum alloy foil manufactured through a single rolling is exemplified.

[0074] (for test material production)

[0075] (Example No.1-10, Comparative Example No.11-19)

[0076] Aluminum alloys having the compositions shown in Table 1 were melted and cast to form ingots, and after face milling the ingots, homogenization heat treatment was performed at 540° C. for 4 hours. The homogenized ingot is hot-rolled, then cold-rolled, and intermediate annealed. Thereafter, cold rolling was performed under conditions of foil rolling by single rolling until a part was removed to a thickness of 15 μm to obtain an aluminum alloy foil. The conditions of the intermediate annealing are that a continuous annealing furnace is used, the annealing temperature is 450°C, the heating rate is 10°C / sec, the cooling rate is 20°C / sec, and the holding time is 5 seconds. The thickness of the plate (foil texture) after hot rolling is 3.5 mm, and the thickness of the plat...

Embodiment 2

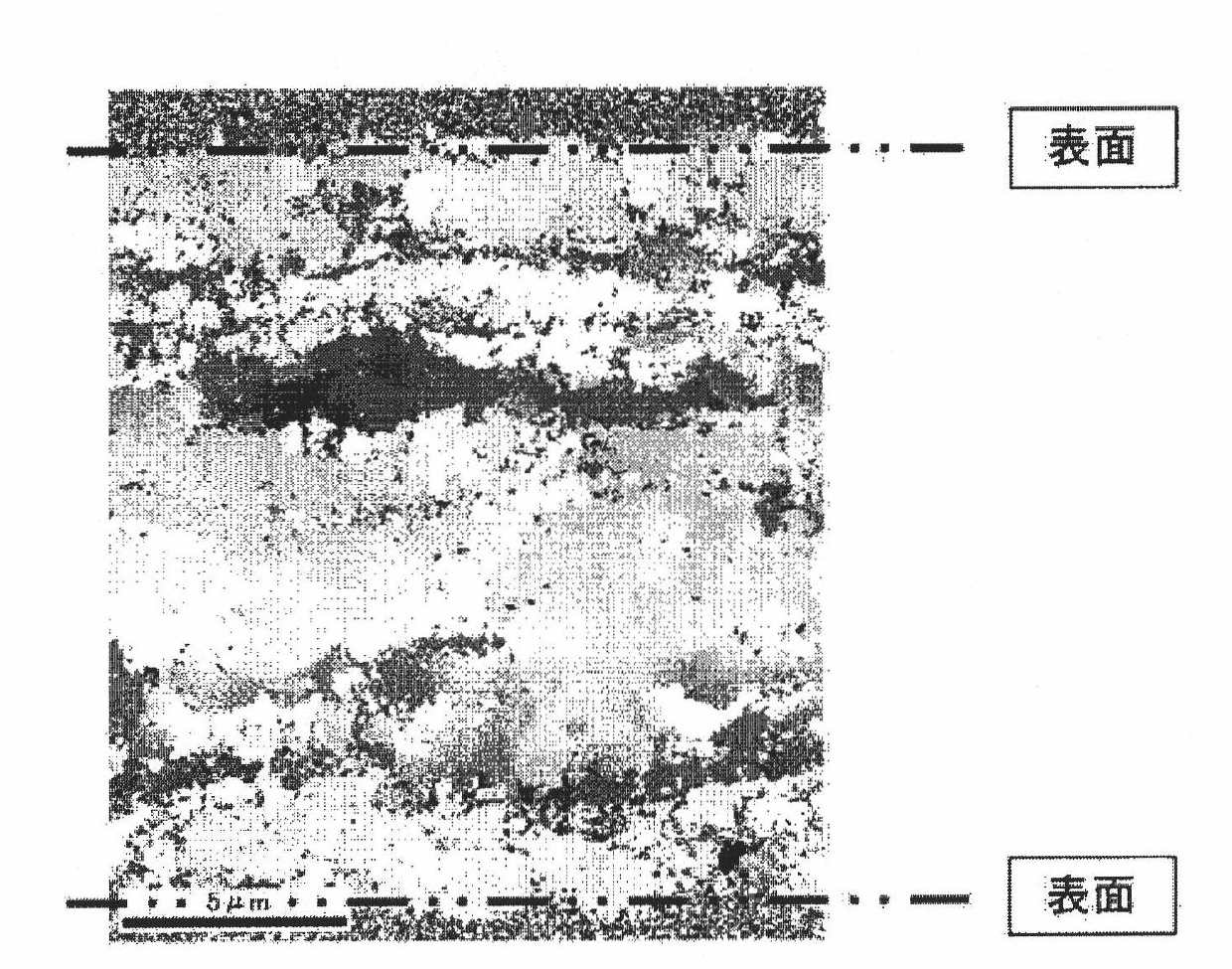

[0107] Next, an example of an aluminum alloy foil manufactured by double-pass rolling will be described.

[0108] (Example No.101-110, Comparative Example No.111-119)

[0109]Aluminum alloys having the compositions shown in Table 3 were melted and cast to form ingots, and after face milling the ingots, homogenization heat treatment was performed at 540° C. for 4 hours. The homogenized ingot is hot-rolled, then cold-rolled, and intermediate annealed. Thereafter, cold rolling was performed under the conditions of foil rolling by overlap rolling until a part was removed to an average thickness of 12 μm to obtain an aluminum alloy foil. The conditions of the intermediate annealing are that a continuous annealing furnace is used, the annealing temperature is 450°C, the heating rate is 10°C / sec, the cooling rate is 20°C / sec, and the holding time is 5 seconds. The thickness of the plate (foil texture) after hot rolling is 3.0 mm, and the thickness of the plate (foil texture) before...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com