Preparation method of ternary material with high cycle and stable structure

A ternary material and a stable structure technology, applied in structural parts, electrical components, electrochemical generators, etc., can solve the problems of capacity, cycle performance, and poor high-temperature storage performance, so as to reduce cation mixing, improve cycle performance, easy processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

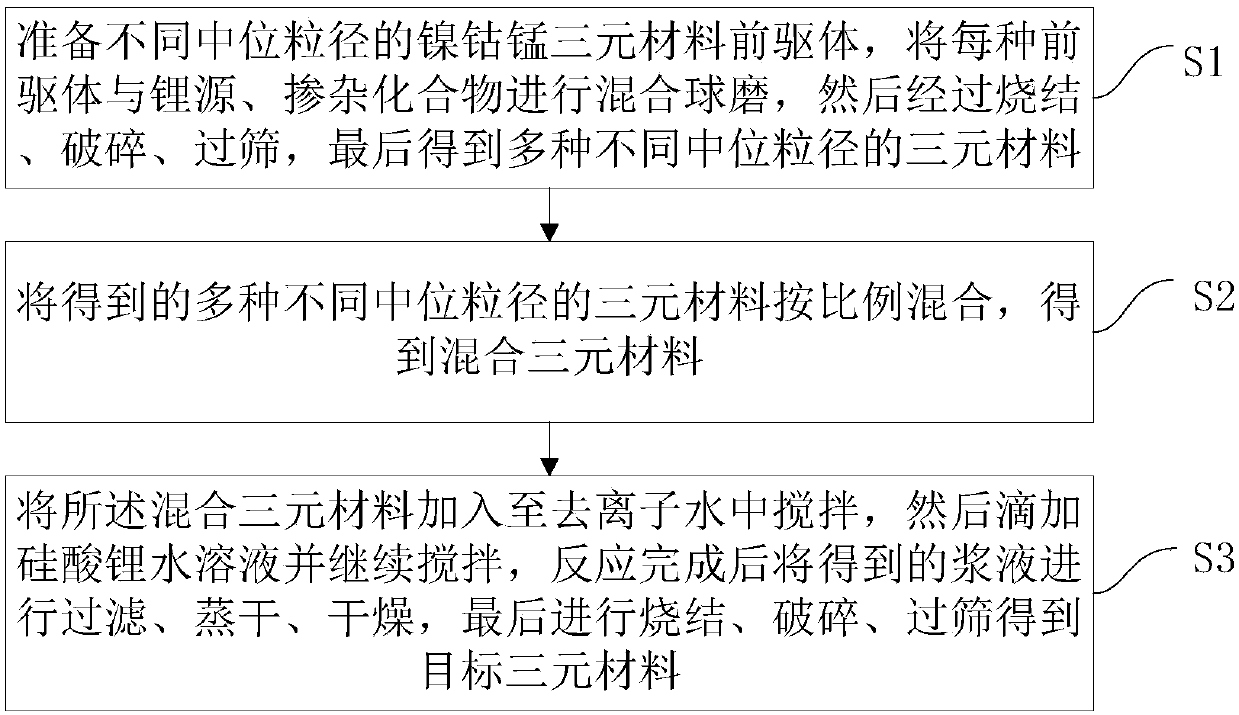

[0027] Such as figure 1 As shown, the high cycle and structurally stable ternary material preparation method provided by the present invention comprises the following steps:

[0028] S1. Prepare nickel-cobalt-manganese ternary material precursors with different median particle sizes, mix and ball-mill the nickel-cobalt-manganese ternary material precursors with each median particle size with lithium source and doping compound, and then sinter and crush , sieving, and finally obtain a variety of ternary materials with different median particle sizes;

[0029] S2, mixing the obtained ternary materials with different median particle sizes in proportion to obtain a mixed ternary material;

[0030] S3. Add the mixed ternary material into deionized water and stir, then dropwise add lithium silicate aqueous solution and continue to stir, after the reaction is completed, filter the obtained slurry, evaporate to dryness, dry, and finally sinter, crush, and sieve Get the target ternar...

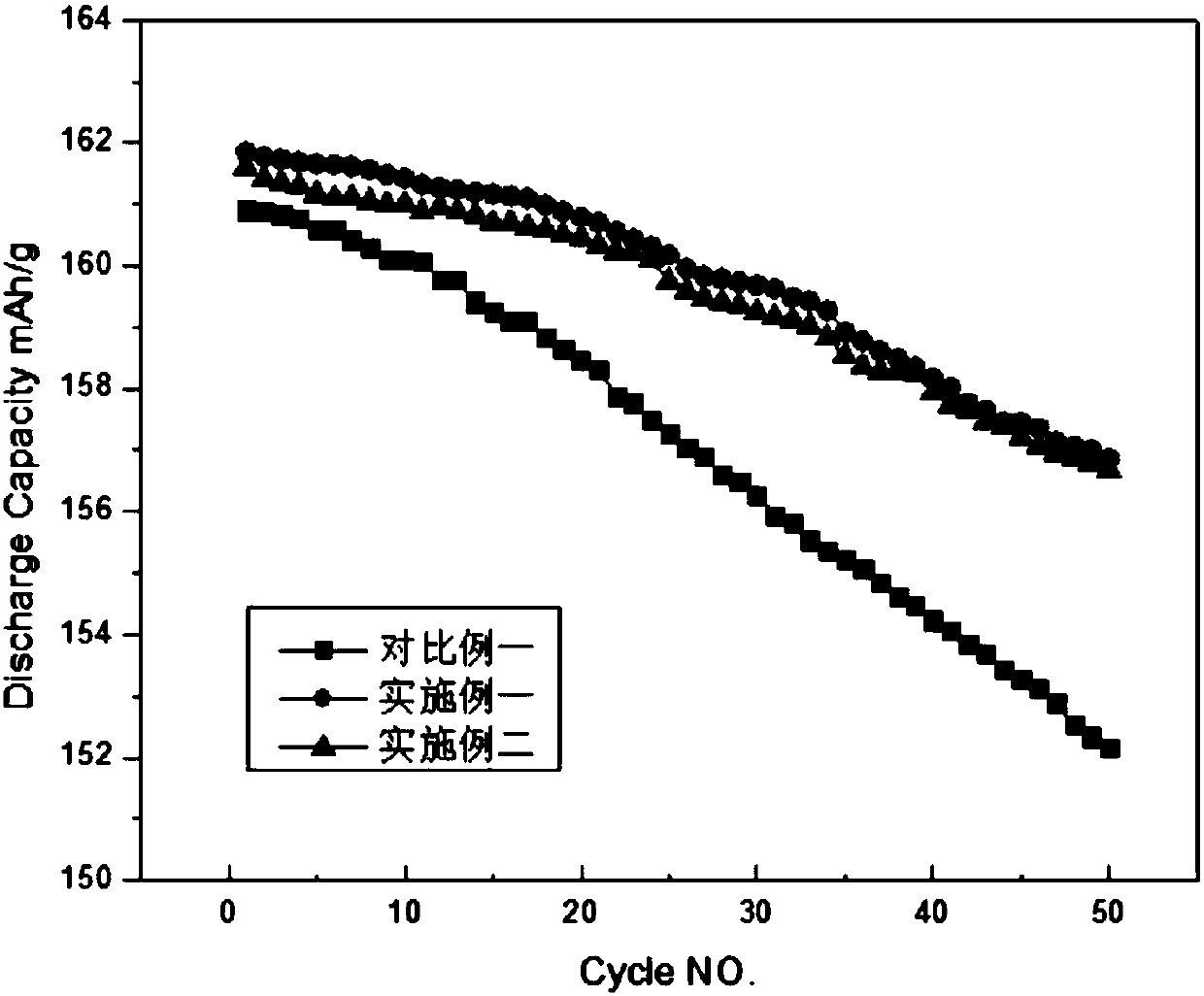

Embodiment 1

[0037] Select Ni with a median particle size of 15 μm 0.5 co 0.2 mn 0.3 (OH) 2, according to Li / Me=1.03, weigh Ni 0.5 co 0.2 mn 0.3 (OH) 2 , Li 2 CO 3 and a doping compound, the doping amount of the F element in the doping compound is 1500ppm, the doping amount of the Si element is 1500ppm, and the doping amount of the Co element is 12000ppm. Mix them by ball milling for 2 hours, place them in a roasting furnace, and roast them at 910°C for 10 hours in an air atmosphere. After the roasted products are crushed and sieved, D 50 14.0μm NCM523 ternary material.

[0038] Select Ni with a median particle size of 6 μm 0.5 co 0.2 mn 0.3 (OH) 2 , according to Li / Me=1.03, weigh Ni 0.5 co 0.2 mn 0.3 (OH) 2 , Li 2 CO 3 and a doping compound, the doping amount of F element in the doping compound is 1500ppm; the doping amount of Si element is 1500ppm, and the doping amount of Co element is 12000ppm. They were ball milled and mixed for 2 hours, and calcined at 900°C for 1...

Embodiment 2

[0042] Select Ni with a median particle size of 15 μm 0.5 co 0.2 mn 0.3 (OH) 2 , according to Li / Me=1.03, weigh Ni 0.5 co 0.2 mn 0.3 o 2 , Li 2 CO 3 and a doping compound, the doping amount of F element in the doping compound is 2000ppm; the doping amount of Si element is 2000ppm. They were ball milled and mixed for 3 hours, then placed in a roaster, and roasted at 930°C for 10 hours in an air atmosphere; after the roasted product was crushed and sieved, D 50 14.0μm NCM523 ternary material.

[0043] Select Ni with a median particle size of 6 μm 0.5 co 0.2 mn 0.3 (OH) 2 , according to Li / Me=1.03, weigh Ni 0.5 co 0.2 mn 0.3 (OH) 2 , Li 2 CO 3 and the source compounds of each doping element, wherein the doping amount of F element is 2000ppm; the doping amount of Si element is 2000ppm, and the doping amount of Co element is 12000ppm. They were ball milled and mixed for 3 hours, then placed in a roaster, and roasted at 920°C for 10 hours in an air atmosphere; af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com