Water-base lubricating fluid for aluminum cold-rolling and preparation method thereof

A technology of water-based lubricating fluid and lubricating additive, applied in lubricating composition, petroleum industry, additives, etc., can solve the problems of poor lubricating performance, reduced rolling effect, easy volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

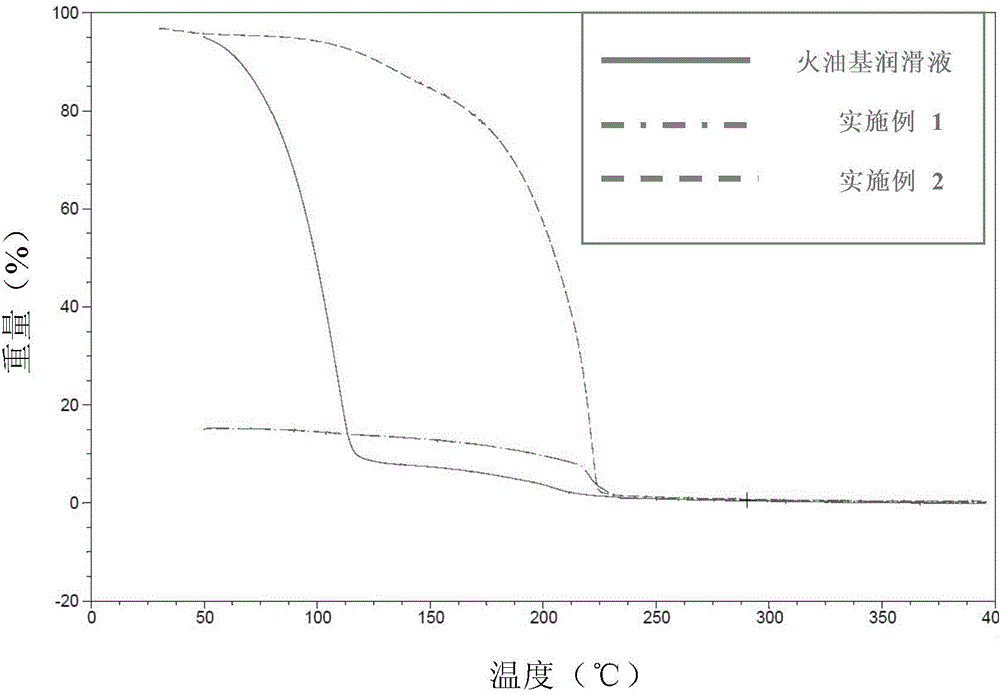

Image

Examples

Embodiment 1

[0026] A single-phase water-based lubricating fluid for aluminum cold rolling. The water-based lubricating fluid is composed of the following components by weight percentage: polyoxyethylene-polypropylene polymer (molecular weight: 1000) 10%, polyoxyethylene Phosphate ester 1%, benzotriazole 0.5%, and the rest made up with deionized water.

[0027] The preparation method of the above-mentioned single-phase water-based lubricating liquid for aluminum cold rolling, the steps are: first pour half of the above-mentioned polyoxyethylene-polypropylene polymer into a container, and then pour polyoxyethylene phosphate and benzotriazole Pour into containers one by one, heat to 50°C and stir evenly until all components are completely dissolved, and finally add the remaining amount of polyoxyethylene-polypropylene polymer and stir well.

Embodiment 2

[0029] A single-phase water-based lubricating fluid for aluminum cold rolling. The lubricant is composed of the following components by weight percentage: polyethylene glycol (molecular weight: 200) 90%, polyoxyethylene phosphate 1%, benzene Triazole 0.5%, triethanolamine 1.5%, and the rest are supplemented with deionized water.

[0030] The preparation method of the above-mentioned single-phase water-based lubricating liquid for aluminum cold rolling, the steps are: first pour half of the above-mentioned polyethylene glycol into a container, and then pour polyoxyethylene phosphate, benzotriazole and triethanolamine in sequence Pour into a container, heat to 50°C and stir evenly until all components are completely dissolved, then add the remaining amount of polyethylene glycol and stir well.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com