Road pavement repairing device for highway bridge construction

A technology for road pavement and road bridges, which is applied in the field of road pavement repair devices, can solve the problems of low pavement repair efficiency and large labor input, and achieve the effect of improving the leveling repair efficiency and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

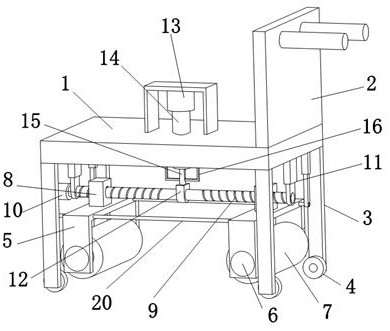

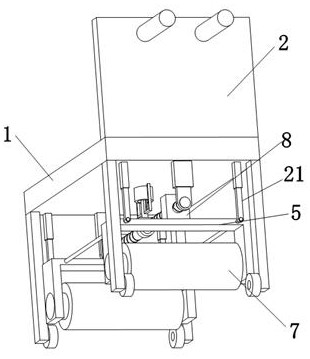

[0024] like Figure 1-3 As shown, the present invention includes a base plate 1, the bottom of the base plate 1 is provided with support columns 3 around, the top side of the base plate 1 is provided with a push plate 2, the rear side of the push plate 2 is provided with a control panel, and the control panel is provided with a control device The button for starting and stopping; the bottom end of the support column 3 is provided with a moving wheel 4, through the design of the moving wheel 4, it is convenient to realize the movement of the device, and the bottom of the base plate 1 is symmetrically provided with two mounting plates 5, and the two mounting plates 5 The bottom ends are provided with mounting shafts 6, and the mounting shafts 6 are provided with pressure rollers 7. A driving motor is fixed on one side of the mounting plate 5, and the output shaft of the driving motor is fixedly connected with the mounting shafts 6; by controlling the rotation of the driving motor...

Embodiment 2

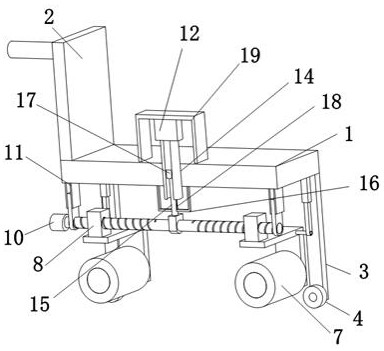

[0032] Based on the above-mentioned embodiment 1, during the road surface repair process, the pressure roller 7 is easy to adhere to the repair material, which affects the repair of the pressure road repair. It can only be leveled after repeated rolling, which leads to low work efficiency; during the rolling process, the low-lying places cannot be avoided when encountering low-lying places, resulting in the low-lying places being rolled and making them lower than the repaired road surface. Therefore, in order to solve the above Technical problem, the inventor has carried out following improvement.

[0033] like Figure 4-6 As shown, a road pavement repairing device for highway bridge construction includes a base plate 1, a push plate 2 is provided on the top side of the base plate 1, and support columns 3 are provided around the bottom end of the base plate 1, and the bottom ends of the support columns 3 are arranged A moving wheel 4 is provided, and two mounting plates 5 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com