Kitchen garbage treating machine

A processing machine and kitchen waste technology, applied in the direction of solid waste removal, etc., can solve the problems of difficult installation, noise amplification, loud noise, etc., and achieve the effect of short running time, ensuring electricity safety and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

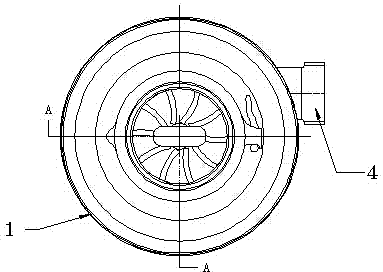

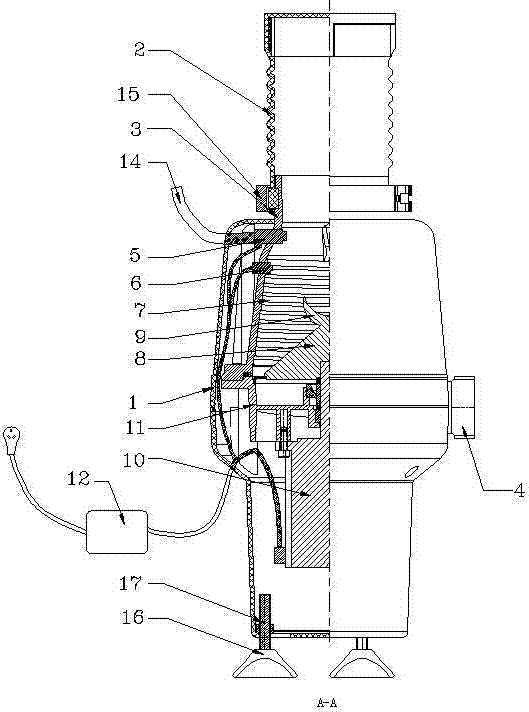

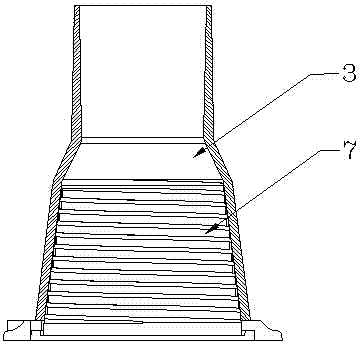

[0022] A food waste processing machine comprises a casing, a coupling piece is arranged on the top of the casing, a water outlet is arranged in the middle of the casing, a suction cup assembly is arranged on the bottom of the casing, and a conical rolling chamber is arranged inside the casing. The inner wall of the rolling chamber is provided with a spiral inverted stepped platform, the upper part of the rolling chamber is provided with an automatic water supply device and a food waste detection head, and the lower part of the rolling chamber is provided with a rolling plate. A crushing ax is arranged on the center of the rolling plate, and the lower end of the rolling plate is connected with the motor. A drainage chamber is arranged at the lower end of the rolling disc, and the drainage chamber is connected with the drainage port. The motor, automatic water feeder and food waste detection head are all connected with the integrated controller.

[0023] Working method: The foo...

Embodiment 2

[0025] A food waste processing machine comprises a casing, a coupling piece is arranged on the top of the casing, a water outlet is arranged in the middle of the casing, a suction cup assembly is arranged on the bottom of the casing, and a conical rolling chamber is arranged inside the casing. The inner wall of the rolling chamber is provided with a spiral inverted stepped platform, the upper part of the rolling chamber is provided with an automatic water supply device and a food waste detection head, and the lower part of the rolling chamber is provided with a rolling plate. The rolling plate is conical, and the rolling plate is provided with raised spiral steps along the circumference. The spiral steps are bar-shaped, and there are at least two spiral steps. The raised spiral steps can increase the contact area between the rolling disc and the food waste, and improve the crushing efficiency of the food waste.

[0026] Other structures and working process are identical with ...

Embodiment 3

[0028] A food waste processing machine comprises a casing, a coupling piece is arranged on the top of the casing, a water outlet is arranged in the middle of the casing, a suction cup assembly is arranged on the bottom of the casing, and a conical rolling chamber is arranged inside the casing. The inner wall of the rolling chamber is provided with a spiral inverted stepped platform, the upper part of the rolling chamber is provided with an automatic water supply device and a food waste detection head, and the lower part of the rolling chamber is provided with a rolling plate. The lower end of the connecting piece is provided with a projection, and the outer end of the projection is provided with a locking buckle, and the connecting piece is connected with the upper end of the rolling bin through the locking buckle. The locking buckle is used to realize the connection between the connecting piece and the rolling chamber, which has simple structure, reliable performance, convenie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com