Buried full medium optical cable

An all-dielectric and optical cable technology, applied in the direction of fiber mechanical structure, etc., can solve the problems of unreachable, poor lateral pressure resistance, difficulty in meeting the mechanical performance requirements of direct burial, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

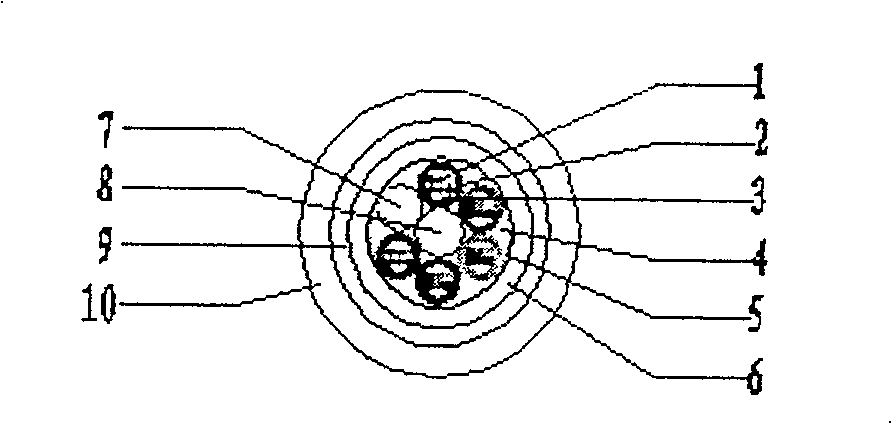

[0010] Example: such as figure 1 As shown, the cable core adopts a 1+6 structure with 30 cores, that is, 5 bundle tubes 2 (6 cores / tube) + 1 filling rope 7 and a central reinforcement 8. The central reinforcement in this embodiment is FRP (glass Fiber-reinforced plastic round rod), the modulus of elasticity of FRP is 50GPa, the diameter is 2.1mm, each bundle tube contains 6 optical fibers 1, the excess length of the fiber in the bundle tube is 0.6-1.0‰, the bundle tube in the cable core adopts SZ stranding, twisted The joint pitch / twisting angle is 60-70mm / 10π, and the glass fiber yarn 9 is used as a tensile element for the outer wrapping of the cable core. Due to the reasonable excess length of the optical fiber and the small twisting pitch, the present invention makes the performance of the optical cable normal in direct burial environment, high tensile strength and other severe mechanical performance requirements and high and low temperature operation; the outer longitudina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com